Plate Heat Exchanger Catalogues for Modern Industries

An engineer faces a significant challenge when selecting the right heat exchanger. A plate heat exchanger catalogue serves as the primary engineering tool for this task. It guides engineers in matching specific heat exchanger types to demanding applications in modern industries.

Using a Plate Heat Exchanger Catalogue for HVAC and Food Processing

Engineers in the HVAC and food processing sectors rely on specific heat exchanger types to meet demands for both performance and compliance. A detailed plate heat exchanger catalogue is the essential guide for navigating these choices, clearly outlining models suited for flexible operations versus those designed for standardized duties.

Gasketed PHEs for Flexible Operations

Gasketed plate heat exchangers (GPHEs) provide exceptional operational flexibility. Their design features removable plates and gaskets, which permits convenient access for cleaning, maintenance, and component replacement. This characteristic makes them an ideal solution for applications requiring frequent servicing, such as in food processing and commercial HVAC.

Hygienic Design for Food & Beverage In food processing, equipment must prevent contamination and be easy to clean. GPHEs selected for these roles must adhere to stringent hygienic design principles, often requiring certification to standards like:

·3-A Sanitary Standards, especially for dairy.

·EHEDG (European Hygienic Engineering and Design Group) Guidelines.

Gasket materials are also critical, with options like PTFE offering excellent resistance to acids and NBR providing reliable sealing with oils.

In HVAC, GPHEs are commonly used for free cooling, typically operating with water temperatures between 45°F and 55°F.

Brazed PHEs for Standardized Duties

Brazed plate heat exchangers (BPHEs) offer a compact and highly efficient solution for standardized applications. Unlike gasketed models, their plates are permanently brazed together, creating a durable, leak-proof unit. BPHEs demonstrate superior thermal performance compared to older shell-and-tube exchangers, primarily due to a design that maximizes counter-current flow. This allows for a closer temperature approach and greater efficiency.

Engineers use BPHEs extensively in refrigeration and air conditioning systems for roles such as:

·Evaporators and condensers in chillers and heat pumps

·Economizers for cooling liquid refrigerant

·Sub-coolers in refrigeration cycles

These standardized units are readily available for quick deployment in systems where high performance and a small footprint are paramount.

Navigating Demanding Conditions in Heavy Industry

Heavy industries present some of the most challenging thermal management scenarios. Engineers in these sectors must select equipment that withstands extreme pressures, temperatures, and difficult media. A comprehensive plate heat exchanger catalogue is indispensable for identifying robust solutions tailored to these environments.

Welded PHEs for High Pressure and Temperature

Welded plate heat exchangers are engineered for durability in demanding process applications. Their gasket-free, all-welded construction eliminates the primary weak point of traditional designs, enabling them to operate reliably at pressures exceeding 1,015 psi and temperatures up to 1,202°F (650°C). This makes them essential in sectors where performance cannot be compromised.

Key applications include:

·Oil & Gas: Used in crude oil preheating and gas purification, where they handle high-pressure hydrocarbon streams.

·Chemical Processing: Ideal for managing aggressive fluids and controlling reaction temperatures.

·Power Generation: Employed in closed-loop cooling systems where preventing fluid loss is critical.

Mitigating Common Failure RisksThe robust, welded design directly addresses critical failure modes common in high-stress environments. By eliminating gaskets, these units significantly reduce the risk of leakage due to seal failure. Their sturdy construction also provides superior resistance to vibration and corrosion, ensuring long-term operational integrity.

Wide-Gap Models for Viscous or Particulate Fluids

Processing fluids with suspended solids, fibers, or high viscosity poses a significant risk of clogging. Wide-gap plate heat exchangers solve this problem with a specialized design. These models feature extra-wide channels—sometimes up to 10 mm—that allow media like slurries, sludge, and fiber-laden process streams to flow smoothly.

This design effectively prevents fouling and blockages, which translates to longer operational cycles and lower maintenance costs. Engineers frequently specify these units for applications in the pulp and paper industry to handle black liquor or in chemical plants for processing special media. The result is reliable, efficient heat transfer without the downtime associated with conventional designs.

Sourcing Solutions for Specialized and Emerging Technologies

As industries advance, the demand for highly specialized thermal management solutions grows. A comprehensive plate heat exchanger catalogue is the engineer's guide to finding innovative designs for unique and high-tech applications, moving beyond standard configurations to address specific process needs.

Pillow Plates for Tank and Vessel Heating

Pillow plate heat exchangers offer a versatile solution for heating and cooling large tanks and vessels. These components feature a unique, inflated "pillow" structure created by welding two metal sheets together. This design provides a large surface area for efficient heat transfer and excellent structural integrity for pressure handling. Engineers often specify them as integrated heating or cooling jackets for tanks in food production, chemical processing, and other industries requiring stable temperature control for large volumes.

Calculating Performance:The effectiveness of a pillow plate depends on the overall heat transfer coefficient (k), which accounts for the fluid properties, material conductivity (λ), and potential for fouling (Rf). Specialized software helps engineers model these variables to ensure optimal performance in tank applications.

Printed Circuit Heat Exchangers (PCHEs) for High-Tech Uses

Printed Circuit Heat Exchangers (PCHEs) represent the cutting edge of thermal management technology. Manufacturers create these units by chemically etching intricate micro-channels onto metal plates, which are then stacked and diffusion-bonded into a solid block. This process results in an exceptionally compact, lightweight, and robust heat exchanger with superior thermal efficiency.

PCHEs can withstand extreme pressures and temperatures, making them indispensable in advanced and emerging sectors. Their high power density and resilience are critical for:

·Green hydrogen production and liquefaction

·Aerospace thermal management systems

·Cryogenic applications, including LNG facilities

·Advanced manufacturing processes

By using materials like corrosion-resistant alloys (CRAs) and nickel-based superalloys, PCHEs provide reliable performance in the most demanding environments, from deep-sea equipment to space exploration hardware.

Optimizing Energy Efficiency Across Applications

Maximizing energy efficiency is a primary goal across all industries. Plate heat exchangers are central to this effort, offering advanced solutions for waste heat recovery and tailored performance. Government incentives, including federal tax credits and utility rebates, further encourage the adoption of these high-efficiency systems.

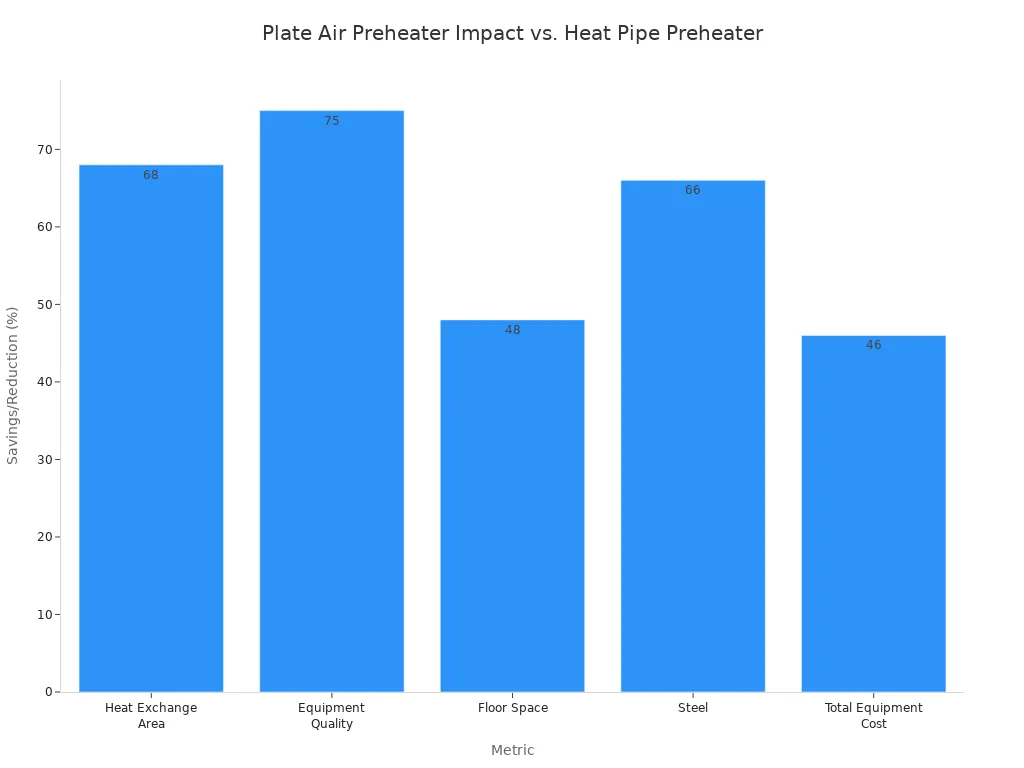

Plate Air Preheaters for Waste Heat Recovery

Plate air preheaters are specifically designed to recover valuable heat from exhaust streams. In industrial processes, flue gas temperatures can exceed 1100°C, representing a significant source of wasted energy. These units capture this thermal energy and use it to preheat incoming combustion air. This process can increase combustion efficiency to nearly 99% and reduce fuel consumption. The optimized plate structure enhances heat transfer while minimizing airflow resistance. As a result, plate air preheaters offer substantial advantages over other technologies.

Custom Solutions for Unique Process Needs

Standard models may not fit every application. A comprehensive plate heat exchanger catalogue often includes options for custom-engineered solutions. Industries like food processing, pharmaceuticals, and chemical manufacturing have unique requirements that demand specialized designs. For example, a food producer might need a specific plate configuration to achieve the correct texture for creamy peanut butter.

Designing with Precision ⚙️ Engineers use advanced tools like Computational Fluid Dynamics (CFD) to design and validate these custom units. CFD simulations help:

·Optimize flow paths to maximize heat transfer.

·Predict pressure drop across the unit.

·Select materials resistant to corrosion and fouling.

This digital modeling ensures the final product delivers optimal performance for the specific process.

A plate heat exchanger catalogue is more than a product list; it is a critical resource for solving complex thermal challenges. Engineers use this key resource to avoid common selection errors and choose optimal materials for long-term reliability. By understanding how to navigate these documents, they can confidently select and implement the most effective heat transfer solutions for any industrial application.

FAQ

How do engineers choose between gasketed and welded PHEs?

Gasketed models offer easy maintenance for hygienic uses. Welded units provide high durability for extreme pressure and temperature applications in heavy industry.

What is the most important factor in material selection?

Engineers prioritize fluid compatibility. The material must resist corrosion from the process media. This ensures long-term reliability and prevents leaks in the system.

How does a catalogue help with custom designs?

Catalogues provide performance data for standard components. Engineers use this data as a baseline to develop custom solutions for unique process requirements.