Heat Exchangers 101 Their Function and Importance

Understanding What Heat Exchanger Is and How It Works

A deep dive into this technology reveals a device governed by fundamental physics. Understanding what heat exchanger systems do begins with the principles of thermodynamics and heat transfer. These concepts explain how energy moves from a warmer substance to a cooler one, forming the basis of every heating and cooling application.

The Core Principle of Heat Transfer

Heat exchangers operate according to the foundational laws of thermodynamics. These laws dictate how energy behaves within a closed system.

·The First Law of Thermodynamics: This principle is about energy conservation. It states that energy cannot be created or destroyed, only transferred or changed from one form to another. A heat exchanger moves thermal energy from one fluid to another without any net energy loss.

·The Second Law of Thermodynamics: This law governs the direction of energy transfer. Heat naturally flows from a hotter medium to a colder one. This principle ensures the process is spontaneous and defines the efficiency of the energy exchange.

This transfer of thermal energy occurs through three primary mechanisms: conduction, convection, and radiation. Most heat exchangers rely heavily on conduction and convection.

| Feature | Conduction | Convection | Radiation |

|---|---|---|---|

| Mechanism | Direct contact between objects | Movement of a fluid | Electromagnetic waves |

| Medium | Through a solid object | Through fluids like air or water | Occurs without particles |

| Speed | Slow | Faster | Fastest |

A Practical Example: Your Home Furnace

To understand what heat exchanger technology looks like in practice, consider a residential gas furnace. The heat exchanger is the component responsible for safely warming the air that heats your home. It sits between the combustion chamber, where fuel burns, and the blower system.

The process unfolds in a few simple steps:

1.Natural gas or oil burns inside the combustion chamber, producing extremely hot combustion gases.

2.These hot gases flow into the heat exchanger, a series of metal tubes or shells. The heat transfers from the gases to the metal walls via conduction.

3.Simultaneously, the furnace's blower fan circulates cooler air from your home across the exterior surfaces of the hot heat exchanger.

4.The air absorbs heat from the metal via convection, becoming warm.

5.The system then distributes this heated air through your home's ductwork. Meanwhile, the harmful combustion byproducts (like carbon monoxide) are safely contained within the heat exchanger and vented outside through a flue pipe.

Important Note: The heat exchanger ensures the air you breathe never mixes with the toxic exhaust gases. This separation is critical for both efficiency and safety.

Common Types of Heat Exchangers

Engineers have developed numerous heat exchanger designs to meet diverse industrial and commercial needs. The choice of type depends on factors like the fluids involved, pressure and temperature requirements, and space constraints. Here are four common types.

1. Shell-and-Tube Heat ExchangersThis is a workhorse of heavy industry. It consists of a large cylindrical shell containing a bundle of tubes. One fluid flows through the tubes while another flows over them within the shell. Their robust construction makes them ideal for high-pressure and high-temperature applications in oil refineries, chemical processing plants, and power generation facilities.

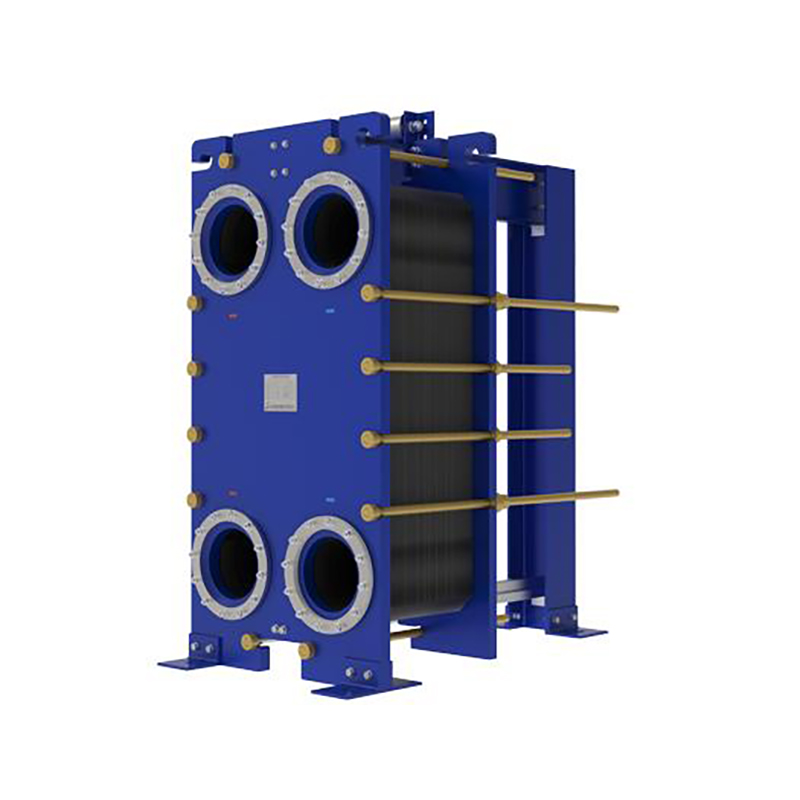

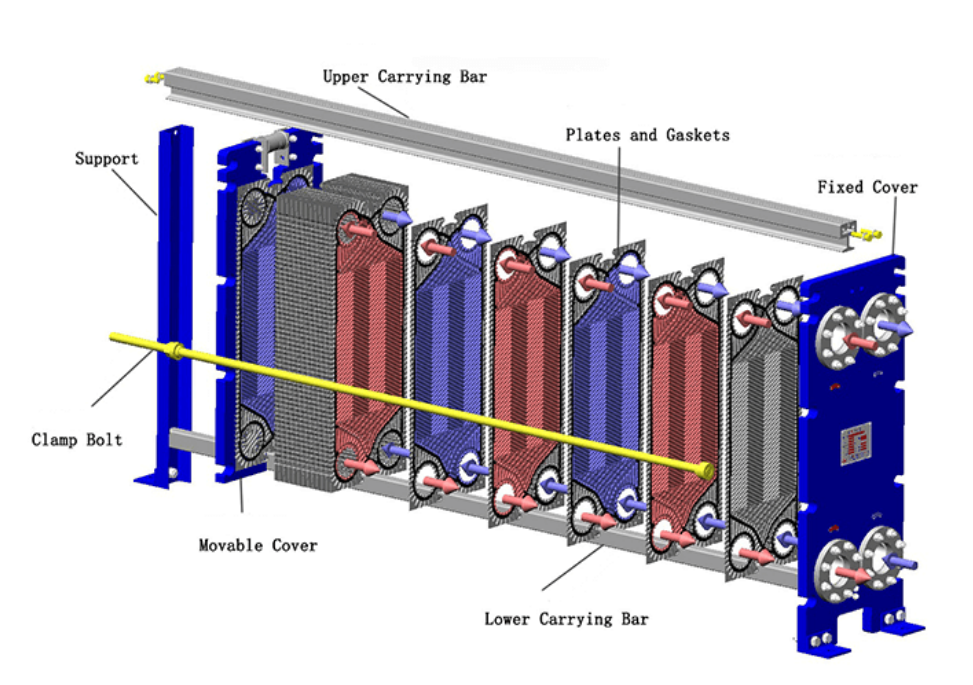

2. Plate-and-Frame Heat ExchangersThese units use a series of thin, corrugated metal plates to create flow paths. The design creates high turbulence, leading to very efficient heat transfer in a compact size. This makes them popular in the food, beverage, and pharmaceutical industries.

·Gasketed types allow for easy disassembly for cleaning and maintenance.

·Brazed types are permanently sealed and offer a compact, economic solution for refrigeration and industrial tasks.

·Welded types provide maximum durability for high temperatures and corrosive materials. An advanced example is the HT-Bloc Welded Plate Heat Exchanger. It combines the high efficiency of plate designs with the high pressure and temperature resistance of shell-and-tube models. Its gasket-free construction ensures robust, leak-resistant performance for critical applications. This design helps professionals understand what heat exchanger innovation can achieve.

3. Air-Cooled Heat ExchangersThese exchangers use ambient air to cool a fluid flowing through finned tubes. A large fan forces or induces air across the tubes to dissipate heat. They are common in locations where water is scarce or expensive, such as arid regions or remote facilities. While their initial capital cost can be higher, their operating costs are often lower due to minimal water usage and reduced maintenance. You can find them in petrochemical plants and refrigeration systems.

4. Spiral Heat Exchangers A spiral heat exchanger is made by rolling two long metal plates around a central core to form a pair of concentric spiral channels. This unique design is excellent for handling fluids with high solids content, like sludges and slurries, because the single-channel flow path creates a self-cleaning effect that reduces fouling. They are highly efficient and compact, serving specialized roles in wastewater treatment, mining, and paper manufacturing.

The Importance and Risks of Heat Exchangers

Heat exchangers are fundamental to modern life. They provide comfort, enable industrial production, and drive efficiency. Their function, however, carries inherent responsibilities. A properly maintained unit is a model of efficiency and safety. A neglected one can become a significant financial and health liability. Understanding both the benefits and the risks is essential for any system owner.

Energy Efficiency and Cost Savings

Heat exchangers are masters of energy conservation. They capture and reuse thermal energy that would otherwise go to waste. This process significantly reduces fuel consumption and lowers operational costs. In an industrial setting, this means recovering heat from an exhaust stream to preheat an incoming fluid. In a residential setting, it means getting the most warmth from every unit of fuel.

Upgrading to a high-efficiency furnace with a modern heat exchanger offers substantial savings. The Department of Energy reports that homeowners can cut heating bills by up to 20% with such an upgrade. The long-term financial benefits are even more compelling.

| Upgrade Scenario | Annual Savings Percentage | Total Savings Over 5 Years | Total Savings Over 10 Years | Total Savings Over 15 Years |

|---|---|---|---|---|

| From 60% AFUE to 80% AFUE | 25% on home heating costs | $2,506 | $5,012 | $7,518 |

These savings demonstrate how an efficient heat exchanger directly translates into lower utility bills year after year.

The Critical Role in Safety

Beyond efficiency, heat exchangers play a vital role in operational safety across countless applications. They maintain stable operating temperatures, preventing equipment from overheating and failing catastrophically.

·Automotive Systems: A car's radiator is a perfect example. It circulates coolant to absorb immense heat from the engine. The radiator then transfers this heat to the surrounding air. This continuous cycle prevents the engine from overheating, ensuring vehicle reliability and safety.

·Chemical Processing: These facilities rely on heat exchangers to control reaction temperatures, manage corrosive materials, and reuse heat from exhaust streams. This control is vital for maintaining process stability and preventing dangerous thermal runaways.

·Industrial Manufacturing: Heat exchangers cool hydraulic oil, manage furnace temperatures, and support precise heating cycles in processes like injection molding. This protects machinery, ensures product quality, and creates a safer working environment.

In each case, the heat exchanger acts as a silent guardian, managing thermal energy to keep systems running smoothly and safely.

Signs of a Damaged Heat Exchanger

A heat exchanger often provides warning signs before it fails completely. Recognizing these indicators is key to preventing a dangerous situation. Homeowners and facility managers should be alert to any changes in their system's operation.

Audible Clues 👂Strange noises often signal metal stress. The expansion and contraction of a cracked component can produce distinct sounds when the system cycles on and off.

·Rattling Noises: These can occur if a crack develops where pipes connect to the combustion chamber, causing a part to become loose.

·Popping or Banging Sounds: Loud bangs may indicate that the metal walls of the exchanger are flexing due to a fracture. These sounds often worsen over time.

Visual Indicators 👀A visual inspection can reveal physical damage. Look for the following signs near your furnace or boiler:

·Visible cracks or fractures on the unit's surface.

·Significant rust or corrosion, which weakens the metal.

·Soot or black carbon buildup around the burners, indicating incomplete combustion.

·Water pooling on the floor around the unit.

Operational Changes 🔥The behavior of the furnace flame is a critical diagnostic tool.

A healthy gas furnace should produce a steady, blue flame. A change in color or behavior is a major red flag. A yellow or flickering flame suggests that the combustion process is imbalanced, which can be caused by a crack pulling excess air into the chamber.

Dangers of a Cracked Unit

A crack in a heat exchanger is more than a simple mechanical issue; it is a serious safety hazard. The primary function of the device is to keep breathable air separate from toxic combustion gases. A crack destroys this barrier. This failure allows harmful byproducts like carbon monoxide (CO), sulfur dioxide, and nitrous oxide to leak from the sealed combustion chamber and mix with the air circulating through your home or facility.

Carbon monoxide is an odorless, colorless, and tasteless gas that is highly poisonous. Exposure can lead to severe health consequences, and understanding what heat exchanger failure means is critical. Vulnerable individuals, such as infants, the elderly, and those with heart conditions, are at an even greater risk.

| CO Exposure Level | Symptoms | Potential Severe Outcomes |

|---|---|---|

| Low (70 PPM) | Headache, nausea, and fatigue over time. | Long-term heart or brain damage. |

| High (150-200 PPM) | Disorientation, dizziness, and nausea. | Unconsciousness and death. |

| Very High | Headache and dizziness within 20 minutes. | Death within one hour. |

Beyond CO poisoning, these leaks degrade indoor air quality, circulating pollutants that can trigger allergies, asthma, and other respiratory problems.

The Need for Professional Maintenance

Heat exchangers are built to last, with many manufacturers offering warranties of 20 years or even a lifetime. However, their lifespan depends heavily on proper care. Factors like poor installation, moisture-related corrosion, or neglected air filter changes can cause a unit to fail prematurely, often within 15 years.

Because the risks are so high, professional inspection is not optional. A trained technician performs a series of detailed checks that go far beyond a simple visual scan.

1.Visual and Internal Examination: A technician inspects the exterior for rust and cracks and uses tools like a borescope to examine the interior walls for metal fatigue.

2.Operational Checks: They monitor the burner flame for discoloration or rollout when the blower engages.

3.Combustion Analysis: Using specialized equipment, they measure gas levels like carbon monoxide in the flue to ensure complete and safe combustion.

4.Safety Switch Inspection: They test all safety controls, including the high-limit switch, to confirm they function correctly and will shut the system down in an emergency.

5.System-Wide Review: The inspection includes checking air filters, condensate drain lines, and ventilation systems for blockages or wear.

Regular, professional maintenance is the only way to ensure a heat exchanger operates efficiently, safely, and for its full intended lifespan.

A heat exchanger is a vital component for efficient thermal management across countless systems. Its proper function provides significant energy savings and, most critically, protects against hazardous byproducts like carbon monoxide.

Regular professional maintenance is non-negotiable. It prevents dangerous failures and ensures the system's longevity and safe operation.

FAQ

What is the main function of a heat exchanger?

A heat exchanger transfers thermal energy between two mediums. It accomplishes this transfer without allowing the mediums to mix, ensuring efficient and safe heating or cooling processes.

How long does a typical furnace heat exchanger last?

A furnace heat exchanger can last over 20 years with proper care. Regular professional maintenance is essential to prevent premature failure from issues like corrosion or operational stress.

Why is a cracked heat exchanger dangerous?

A crack allows toxic combustion gases, like carbon monoxide, to leak into breathable air. This contamination creates a severe health hazard and compromises indoor air quality.