Essential Tips for Choosing the Best Gasketed Plate Heat Exchanger

Essential Tips for Choosing the Best Gasketed Plate Heat Exchanger

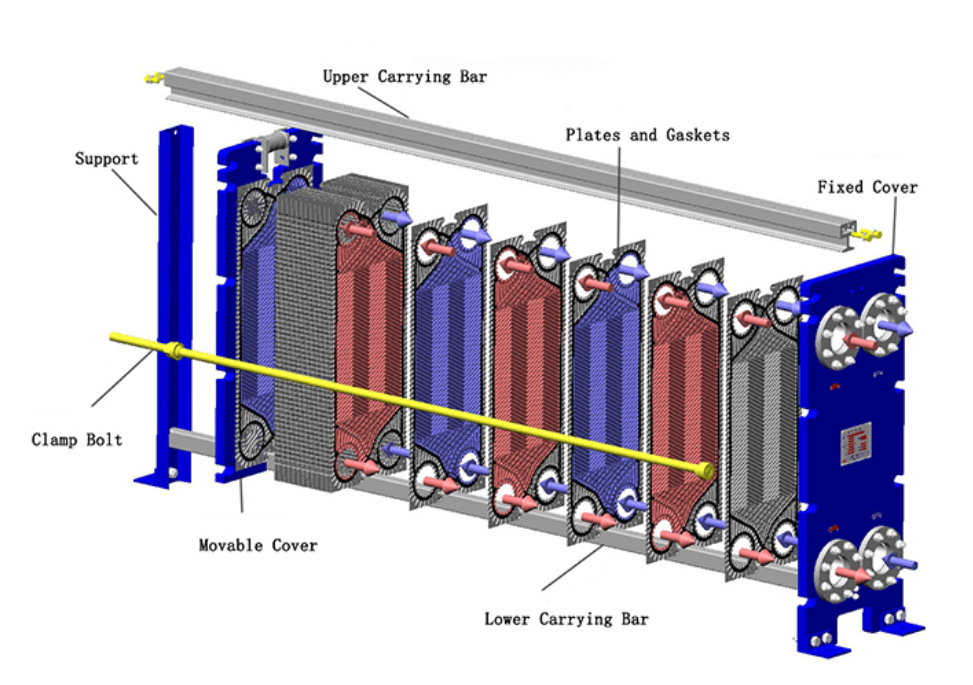

Choosing the best gasketed plate heat exchanger starts with understanding the application’s specific needs. Matching the heat exchanger to the correct temperature, pressure, and fluid type helps prevent common issues like tube leaks, structural deformations, or gasket failures. SHPHE offers advanced features such as modularity, high efficiency, and a range of material options. Considering both operational requirements and future maintenance ensures reliable performance and long-term value.

Operating Conditions

Temperature & Pressure

Selecting a heat exchanger begins with understanding the temperature and pressure limits of the application. Every gasketed plate heat exchanger must operate within safe ranges to maintain performance and reliability. The SHPHE model offers a compact design that handles demanding environments with ease. Operators should always check the recommended ranges before installation.

Temperature Range | Pressure Range |

|---|---|

-45°C to 150°C | Vacuum to 63 barg (900 psig) |

This table shows the typical operating ranges for gasketed plate heat exchangers in industrial settings. Staying within these limits helps protect the unit and ensures efficient energy transfer. High efficiency depends on matching the heat transfer requirements to the correct design specifications.

In a plate HXCH a gasket separates the thin metal plates. The gasket acts to stop the contents escaping from the HXCH and to direct the flows within the HXCH. If incompatible gasket material is selected for the process chemicals and conditions then it will fail early. For example rubber gaskets have a limited temperature range. If the design selection assumes both liquids will be present and a rubber is selected because it will stay cool in the fluid flows then that will be a recipe for disaster.

This block quote highlights the importance of choosing the right gasket material. Operators must consider both the process chemicals and the expected temperature range. Exceeding design limits can lead to early gasket failure and loss of containment.

Flow Rate & Fluid Type

Flow rate and fluid type play a major role in selecting a gasketed plate heat exchanger. The SHPHE design supports a wide range of flow rates and adapts to different fluid properties. Operators should measure the flow rate and analyze the fluid before making a selection.

Factor | Impact on Heat Exchanger Selection |

|---|---|

Viscosity | Determines compatibility with heat exchanger design |

Particulate Content | Affects thermal performance and maintenance requirements |

Fouling Potential | Influences choice of materials and design geometry |

This table lists key fluid factors that affect the selection and efficiency of a gasketed plate heat exchanger. High viscosity fluids may require special plate patterns to maintain energy efficiency. Fluids with high particulate content can increase fouling potential and maintenance needs.

Viscosity

Corrosiveness

Particulate content

Fouling potential

Operators should review these factors to match the heat exchanger to the process. The SHPHE model offers high efficiency and a low fouling design, which helps maintain performance over time. Proper selection ensures the unit meets heat transfer requirements and delivers reliable operation.

Materials & Design

Plate & Gasket Selection

Selecting the right materials for a gasketed plate heat exchanger is essential for reliable operation and long service life. The choice of plate and gasket materials depends on fluid compatibility, corrosion resistance, and the specific heat transfer requirements of the application. Stainless steel, titanium, and Hastelloy are common plate materials. Stainless steel works well for most water-based and mild chemical processes. Titanium resists corrosion in seawater and aggressive fluids. Hastelloy provides excellent durability in highly corrosive environments.

Gasket selection also plays a critical role in performance and compatibility. Operators must match gasket material to the chemical and temperature conditions of the process. EPDM gaskets perform reliably in water and steam systems, handling temperatures from -50°C to 150°C. Nitrile gaskets suit hydrocarbon-based applications, with a temperature range of -40°C to 120°C. Viton gaskets excel in high-temperature, high-pressure, and chemically aggressive environments, tolerating temperatures up to 250°C.

Gasket Material | Temperature Range | Chemical Suitability |

|---|---|---|

EPDM | -50°C to 150°C | Water and steam systems |

Nitrile | -40°C to 120°C | Hydrocarbon-based systems |

Viton | Up to 250°C | High-temperature, chemically aggressive |

Tip: Always verify fluid compatibility before selecting plate and gasket materials. This step helps prevent early failure and ensures optimal performance.

SHPHE offers a wide range of customization options for both plates and gaskets. This flexibility allows operators to tailor the heat exchanger to meet specific process needs and energy goals.

Plate Patterns & Configuration

Plate patterns and configuration have a direct impact on the design and efficiency of a gasketed plate heat exchanger. The arrangement of plates, such as herringbone or chevron patterns, creates turbulence that boosts heat transfer rates. Mixed chevron configurations can further enhance performance by increasing the heat transfer coefficient while managing pressure drop.

Parameter | Effect on Heat Transfer (Nu) | Effect on Pressure Drop (f) |

|---|---|---|

Chevron Angle (β) | Increases with β | Increases with β |

Channel Height | Smaller heights improve | N/A |

Reynolds Number (Re) | Increases Nu by 1.5–2 times | Increases f |

Surface Roughness | Influences coefficients | Influences pressure drop |

Aspect Ratio | Improves effectiveness | N/A |

Operators can adjust plate patterns and channel dimensions to meet specific heat transfer requirements. This level of customization ensures the heat exchanger matches the demands of each process.

SHPHE’s modular design stands out in the industry. The ability to add or remove plates provides scalability and operational flexibility. As process needs change, operators can easily increase or decrease capacity without replacing the entire unit. This adaptability supports long-term energy savings and efficient system upgrades.

Compact and energy-efficient designs help optimize space and reduce costs.

Customization options allow for tailored solutions in industries such as chemical processing and HVAC.

Sustainable practices and eco-friendly materials support modern energy goals.

Recent advancements include digital monitoring for real-time performance tracking and stricter safety standards. These innovations help operators maintain high efficiency and reliability in demanding environments.

Applications & Suitability

Industry Use Cases

Many industries rely on gasketed plate heat exchangers for efficient thermal management. Operators in HVAC systems value high efficiency, compactness, and energy savings. Chemical processing facilities require resistance to corrosive substances and compatibility with specific materials. Food and beverage manufacturers focus on hygiene and precise temperature control. Power generation plants need flexible solutions that handle varying temperatures and pressures.

Industry | Application Requirements |

|---|---|

HVAC | High efficiency, energy saving, compact design, environmental friendliness |

Food and Beverage | Hygiene, temperature control, efficiency in heat transfer |

Chemical Processing | Resistance to corrosive substances, high pressure and temperature handling, material compatibility |

Food processing applications often demand high temperatures and moderate pressures. Power generation processes vary, so operators must assess each system’s needs. Compactness, noise reduction, and seasonal efficiency remain important across all sectors.

Compactness

Noise reduction

Seasonal efficiency

SHPHE’s gasketed plate heat exchanger adapts to these diverse requirements. Its modular design and multi-pass configurations allow operators to optimize performance for each industry.

Matching to Ideal Heat Exchanger

Selecting a heat exchanger involves matching the model to the application’s heat transfer requirements, fluid type, and operating conditions. Operators must consider gasket material, temperature range, and fluid compatibility.

Gasket Material | Application | Temperature Range | Fluid Type |

|---|---|---|---|

EPDM | HVAC, hot water, steam | Lower temperatures | Water, steam, certain chemicals |

NBR | Cooling, general utility | Moderate temperatures | Oil, water-based fluids |

Viton (FKM) | Power generation, chemical | Up to 180-200°C | Corrosive chemicals |

Flexible Graphite | Extreme conditions | Very high | Various fluids |

HNBR | Aggressive fluids | Higher temperatures | Oil, water-based fluids |

Operators should select the ideal heat exchanger by evaluating the process fluid, temperature, and pressure. SHPHE’s operational versatility supports multi-pass arrangements, which help meet specific heat transfer requirements and energy goals. This flexibility ensures reliable performance in demanding applications.

Tip: Review the process conditions and fluid properties before selecting a heat exchanger. This step helps maximize efficiency and extend equipment life.

Installation & Start-Up

Venting & Integration

Proper installation of a gasketed plate heat exchanger helps maintain safety and efficiency. Operators should follow best practices for venting and integrating the unit into existing systems. The first step involves using full penetration welds near the gasket face. This method prevents leaks and ensures a strong seal. In hydrogen service, full penetration welds along the entire length protect against cracking and improve safety. Welding both sides of the pass partition plate and channel adds strength and stops media from entering gaps.

Best Practice | Description |

|---|---|

Full Penetration Welds | The first 50 mm from the gasket face must use full penetration welds to prevent leakage. |

Hydrogen Service | Use full penetration welds along the entire length to avoid cracking and ensure safety. |

Avoid Single-Side Welding | Always weld both sides for strength and to prevent media ingress into the gap between the pass partition plate and the channel. |

Operators should also check system alignment and connections before starting the unit. Proper venting removes trapped air, which helps maintain stable flow and temperature control. SHPHE’s Clean-in-Place compatibility allows for easy integration with automated cleaning systems, reducing downtime and supporting continuous operation.

Initial Checks

Before starting the gasketed plate heat exchanger, operators should perform several initial checks. Plate alignment must be correct to avoid dead zones that lower performance. Water flow should meet the recommended rate to maximize energy transfer. Operators need to inspect for debris, as buildup can block channels and reduce efficiency.

Plate alignment issues can create dead zones and reduce heat transfer.

Insufficient water flow lowers productivity and energy recovery.

Debris accumulation requires regular cleaning to maintain performance.

Routine inspection and cleaning help extend the life of the unit. SHPHE’s design supports quick access for maintenance, making it easier to replace gaskets and clean plates. These steps ensure reliable operation and help achieve optimal energy savings.

Tip: Operators should always follow manufacturer guidelines during installation and start-up. Careful attention to detail protects the system and improves long-term reliability.

Maintenance & Longevity

Inspection & Cleaning

Regular inspection and cleaning help maintain the performance and efficiency of a gasketed plate heat exchanger. Operators should check the unit daily for leaks, unusual noises, or temperature changes. These simple checks can prevent unexpected failures and reduce maintenance requirements. Semi-annual to annual non-destructive testing, such as ultrasonic thickness measurements, allows operators to assess plate integrity and predict potential issues. Chemical cleaning dissolves fouling using acids or alkalis, but operators must control the process to avoid damaging the plates. Mechanical cleaning uses brushes, scrapers, or high-pressure water jets to remove deposits.

Inspection Interval | Method | Description |

|---|---|---|

Semi-annual to Annual | Non-destructive Testing | Ultrasonic or eddy current testing for plate integrity |

Periodic | Chemical Cleaning | Controlled use of acids/alkalis to dissolve fouling |

As Needed | Mechanical Cleaning | Brushes, scrapers, or water jets for physical removal of fouling |

Gasketed plate heat exchangers tend to foul more quickly than shell-and-tube designs because of their intricate flow paths. Rapid deposition can occur without warning, so frequent cleaning is essential. SHPHE’s low fouling design and Clean-in-Place compatibility make routine cleaning easier and help maintain high energy recovery.

Tip: Operators should schedule inspections and cleaning based on process conditions and fouling rates. This approach extends equipment life and supports consistent performance.

Spare Parts & Upgrades

Managing spare parts ensures reliable operation and quick recovery from unexpected downtime. The most frequently required spare parts include plate packs, rubber gaskets, temperature and pressure sensors, and cleaning-in-place adapters.

Spare Part | Description |

|---|---|

Plate packs | Core transfer surfaces; fouling or fatigue reduces efficiency |

Rubber gaskets | Heat and pressure resistant; critical for sealing between plates |

Temperature and pressure sensors | Prevent overheating or mechanical failure |

Cleaning-in-place adapters | Enable safe, efficient chemical cleaning |

Certified suppliers typically provide these parts within a lead time of about 12 weeks. SHPHE’s modular design and easy gasket replacement allow operators to adjust capacity and maintain compatibility with changing process needs. Modular upgrades simplify maintenance and reduce downtime, while quick gasket replacement ensures effective sealing and sustained performance.

Operators find that gasketed plate heat exchangers offer lower lifecycle costs and easier cleaning compared to shell-and-tube models. Industries with frequent cleaning needs, such as food processing, benefit from these advantages. Customization options support long-term reliability and energy savings.

Selecting the ideal heat exchanger requires careful attention to application needs, material compatibility, and maintenance requirements. Industry case studies show that a gasketed plate heat exchanger delivers best performance in food processing, HVAC, and chemical manufacturing. The table below highlights key considerations:

Key Considerations | Description |

|---|---|

Applications | Used in food processing, HVAC, and chemical manufacturing due to their compact and efficient design. |

Maintenance | Modular design allows for easy maintenance and capacity adjustments. |

Installation | Requires specific gasket materials and considerations for flow rates and pressure drops. |

Compliance | Must meet industry standards like ASME or API, especially in food and pharma sectors. |

Cleaning | Supports rigorous cleaning and validation procedures, essential for regulatory compliance. |

Capacity Needs | Proper sizing is crucial to ensure efficiency and prevent over- or under-utilization. |

Long-term reliability depends on regular maintenance and proper sizing, which help optimize energy use and reduce downtime. SHPHE provides technical training, cleaning protocols, and expert support to help operators meet maintenance requirements and achieve best performance.

Regular technical training enhances diagnostic skills.

Structured cleaning protocols improve heat exchange efficiency.

Expert support is available for troubleshooting and upgrades.

Operators can contact SHPHE for guidance and resources to maximize the value of their gasketed plate heat exchanger.

FAQ

What is a gasketed plate heat exchanger used for?

A gasketed plate heat exchanger transfers heat between two fluids without mixing them. Industries use it for heating, cooling, or energy recovery in systems like HVAC, chemical processing, and food production.

How often should operators clean a gasketed plate heat exchanger?

Operators should inspect the unit daily and clean it based on fouling rates. Many facilities schedule cleaning every six months. SHPHE’s Clean-in-Place feature makes this process easier and faster.

Which gasket material should operators choose?

Gasket Type | Best For |

|---|---|

EPDM | Water, steam |

Nitrile | Oil, hydrocarbons |

Viton | High temperature, chemicals |

Operators should match gasket material to the process fluid and temperature.

Can operators expand the capacity of an SHPHE plate heat exchanger?

Yes! SHPHE’s modular design allows operators to add or remove plates. This flexibility helps meet changing process needs without replacing the entire unit.