What Most People Miss About Gasketed Heat Exchanger

Many overlook a simple truth: a gasketed heat exchanger offers impressive heat transfer rates but requires careful attention over time. Users often focus on immediate performance and miss the impact of maintenance in their daily operations. Shanghai Heat Transfer provides expert guidance to help industries choose the right gasketed plate heat exchanger.

Gasketed Heat Exchanger Pros

Flexibility and Customization

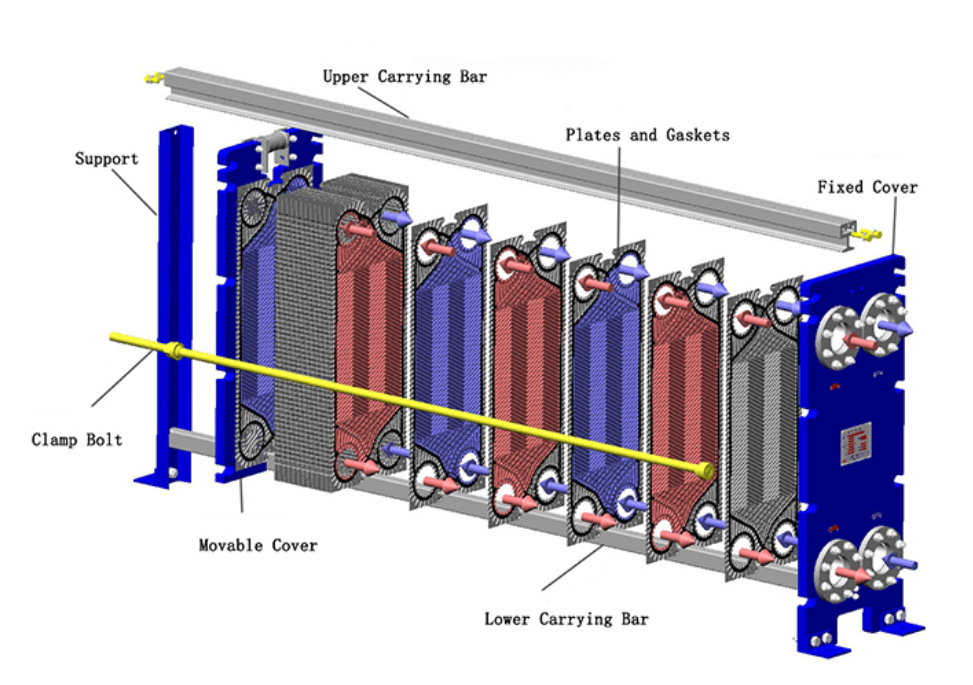

Shanghai Heat Transfer’s Gasketed Plate Heat Exchanger stands out for its flexibility in industrial applications. Operators can select from a wide range of plate and gasket materials, including stainless steel, titanium, and advanced polymers. This variety allows the unit to handle different fluids and temperature ranges. The modular design lets users add or remove plates, making it easy to adjust capacity as production needs change. Many industries value this adaptability because it supports both small and large-scale operations. Customizable accessories and connection types further enhance the unit’s suitability for unique applications.

Easy Maintenance and Cleaning

Gasketed plate heat exchangers offer straightforward maintenance. The plates can be separated quickly, which reduces downtime during cleaning or inspection. Many models, including those from SHPHE, support Clean-in-Place systems. This feature allows operators to clean the unit without taking it apart, saving time and labor costs. The design also helps prevent fouling, which keeps thermal performance high and ensures reliable operation over time.

Compact Design and Space Savings

Industrial plants often face space limitations. Gasketed plate heat exchangers solve this problem with a compact footprint. These units can be up to 80% smaller than traditional shell-and-tube heat exchangers for the same thermal duty. The high surface-area density means more energy transfer in less space. This efficiency allows facilities to maximize production without expanding their physical plant.

High Heat Transfer Efficiency

The gasketed heat exchanger delivers high heat transfer efficiency. The corrugated plate patterns create turbulent flow, which boosts the heat transfer coefficient. Compared to shell-and-tube designs, gasketed plate heat exchangers achieve coefficients between 2,000 and 6,000 W/m²·K. This high thermal performance leads to better energy recovery and lower operating costs in many applications.

Gasketed Heat Exchanger Cons

Gasket Wear and Leakage Risks

Gasketed plate heat exchangers rely on gaskets to keep fluids separated and prevent leaks. Over time, these gaskets can wear out, especially in demanding industrial environments. Many factors can cause leaks, such as high temperature, uneven tightening, or using the wrong gasket material for the fluid. The table below shows common causes of leakage in industrial applications:

Cause Type | Description |

|---|---|

Sealing Gasket Problems | Gaskets lose flexibility from heat, pressure, or chemical attack. |

Plate Problems | Corrosion or deformation of plates can create leak paths. |

Fastener Problems | Incorrect bolt tension can reduce sealing force. |

Operations Problems | Exceeding design limits or sudden changes can damage components. |

Design or Manufacturing Defects | Poor design or manufacturing can introduce weak points. |

Regular inspection and timely gasket replacement help maintain efficiency and thermal performance.

Pressure and Temperature Limits

Gasketed plate heat exchangers have specific limits for pressure and temperature. Most models operate safely up to 25 bar and 180°C. These limits mean that some high-pressure or high-temperature applications require other designs. For example, welded plate heat exchangers handle more extreme conditions. Careful selection ensures safe and reliable operation in each application.

Maintenance Costs Over Time

Maintenance costs play a role in the total cost of ownership. Gasketed plate heat exchangers allow for easy cleaning and plate replacement, which reduces downtime. Over a ten-year period, these units often have lower maintenance costs compared to shell-and-tube exchangers. This advantage supports better energy transfer and long-term performance.

Compatibility Challenges

Material selection is important for long-term reliability. The wrong gasket or plate material can lead to leaks or reduced efficiency. For example, NBR works well with oils, EPDM suits water and steam, and Viton resists acids. Matching materials to fluids in each application helps maintain safety and performance. SHPHE offers expert advice to help users choose the right materials for their needs.

What Most People Miss

Hidden Operational Costs

Many decision-makers focus on the initial price of a gasketed plate heat exchanger and overlook the total cost of ownership. Over the lifespan of the equipment, hidden costs can add up and affect the bottom line. These costs include maintenance, downtime, energy consumption, and replacement parts. The table below highlights the main hidden operational costs that often go unnoticed:

Hidden Costs | Description |

|---|---|

Total Cost of Ownership (TCO) | Includes all expenses over the lifecycle, not just the purchase price. |

Long-term Reliability | Impacts how often maintenance is needed and the associated costs. |

Operational Safety | Safety features help prevent leaks and contamination, which can be expensive to fix. |

Maintenance Efficiency | Efficient designs reduce downtime and labor, lowering operational expenses. |

Energy Efficiency | Optimized designs use less energy, saving money over time. |

When comparing different heat exchangers, the total cost of ownership can be much higher than the initial purchase price. For example, a plate and frame heat exchanger may cost less to buy, but maintenance and replacement costs can add up over 15 years. SHPHE helps clients analyze these factors to make informed decisions for their industrial applications.

Long-Term Reliability

Long-term reliability plays a key role in the success of gasketed plate heat exchangers. Many users miss the impact of material selection and maintenance on reliability. Common issues include gasket failures, fouling, leaks, and mechanical damage. Gasket failures can result from cracking, chemical attack, or exposure to high temperature. Fouling happens when dirt or minerals build up inside the unit, reducing thermal performance. Leaks often occur when gaskets fail or plates become misaligned. Mechanical damage can result from vibration or improper installation.

Proper maintenance and material selection can prevent most reliability issues. For example, using the right gasket material for the fluid and temperature range helps avoid early failures. SHPHE offers regular service and troubleshooting, which can prevent a decrease in heat transfer efficiency by up to 30%. Regular cleaning and inspection keep the unit running smoothly and extend its lifespan.

Overlooked Maintenance Factors

Maintenance planning often misses important details that affect the performance and safety of gasketed plate heat exchangers. Some factors include the presence of chloride ions in process water, which can damage stainless steel and cause leaks. In these cases, switching to titanium or other special alloys can prevent corrosion and extend the life of the equipment. Environmental factors, such as humidity and temperature changes, also influence maintenance needs.

Neglecting maintenance can reduce efficiency and increase operational costs. Gasketed plate heat exchangers can reach up to 95% thermal efficiency, but this drops if cleaning and gasket replacement are ignored. Regular maintenance prevents fouling, leaks, and safety risks. SHPHE provides cleaning and troubleshooting services to help clients maintain high performance and minimize downtime.

Tip: Schedule regular inspections and cleaning to keep your gasketed plate heat exchanger operating at peak efficiency.

Material and Fluid Compatibility

Material and fluid compatibility is a critical factor that many overlook during selection. The wrong choice can lead to corrosion, leaks, and reduced efficiency. The table below shows key considerations for selecting materials in challenging environments:

Material Type | Application/Consideration |

|---|---|

Special Alloys | Use titanium, Hastelloy C276, or 254SMO for highly corrosive media. |

Plate Types | Choose plates with larger corrugation spacing for fluids that scale easily. |

Gasket Material | Match the gasket to the fluid and temperature for best results. |

SHPHE supports clients by recommending the best materials for their specific applications. For example, stainless steel offers excellent resistance to chemical attack and works well with many industrial fluids. Anti-corrosion coatings can further enhance longevity and performance. By considering these factors, users can avoid costly failures and ensure reliable operation in all industrial settings.

Industrial Applications Overview

Chemical Processing

Chemical processing plants demand equipment that can handle aggressive fluids and high temperature conditions. The gasketed plate heat exchanger from SHPHE meets these needs with advanced materials and a modular design. Operators value the high heat transfer efficiency and the ability to manage corrosive fluids. This equipment supports optimal heat transfer and operational reliability in challenging environments. The compact structure also helps reduce costs and supports a lower total cost of ownership.

Food and Beverage

Food and beverage applications require strict hygiene and easy cleaning. The gasketed plate heat exchanger offers a sanitary design that prevents cross-contamination. Its compact size and easy maintenance allow for minimal downtime during cleaning. This feature ensures high thermal performance and effective heat transfer in pasteurization and other sensitive processes. SHPHE provides solutions that help maintain product quality and energy efficiency.

HVAC Systems

HVAC systems rely on gasketed plate heat exchangers for precise indoor climate control. These units deliver energy efficiency and space savings in both residential and commercial buildings. The design supports effective heat transfer and quick installation. Operators benefit from a cost-effective solution that reduces energy use and supports minimal downtime during maintenance.

Power Generation

Power generation facilities use gasketed plate heat exchangers for heat recovery and energy management. These units handle high pressures and temperatures, enhancing efficiency and plant performance. The modular design allows for easy scaling and maintenance. SHPHE supports industrial applications by providing reliable equipment that improves energy recovery and reduces operational costs.

Note: The table below summarizes unique requirements for each sector.

Industry Sector | Unique Requirements |

|---|---|

Chemical Processing | Manage aggressive fluids, operate under demanding temperature conditions. |

Food and Dairy | Sanitary design, hygienic heat treatment, pasteurization. |

HVAC | Precise climate control, energy efficiency. |

Power Generation | Heat recovery, enhance overall plant efficiency. |

Many overlook the impact of maintenance and material selection when choosing a gasketed plate heat exchanger. Key factors include:

Regular gasket checks and replacements

Selection of corrosion-resistant materials

Consideration of temperature and pressure limits

SHPHE offers free technical consultation to help industries optimize plate selection for their unique needs.

FAQ

What makes SHPHE’s gasketed plate heat exchanger different?

SHPHE uses advanced materials and modular designs. Their units offer high efficiency and easy maintenance for many industries.

How often should users inspect gaskets?

Users should inspect gaskets every six months. SHPHE recommends regular checks to prevent leaks and maintain performance.

Can SHPHE help with material selection?

Yes. SHPHE provides expert advice on choosing the best plate and gasket materials for each application.