Thermal Exchanger Types You Should Know and Their Unique Benefits

Types of Heat Exchangers Overview

What Is a Thermal Exchanger

A thermal exchanger, often called a heat exchanger, is a device that moves heat from one fluid to another without mixing them. People use these devices in many systems to heat or cool liquids and gases. They help keep processes running smoothly and support energy efficiency goals. Heat exchangers allow heat transfer between fluids or between a fluid and a solid surface. This process is important in homes, factories, and power plants. When someone wants to save energy or control temperatures, they often rely on different types of heat exchangers.

Did you know? Heat exchangers play a key role in energy efficiency by reducing wasted heat and lowering costs.

Main Types of Heat Exchangers

Many types of heat exchangers exist, each with unique designs and benefits. The main types of heat exchangers include:

Shell and Tube Heat Exchangers

Spiral Heat Exchangers

Air Cooled Heat Exchangers

Double Tube Heat Exchangers

Tube in Tube Heat Exchangers

Regenerative Heat Exchangers

The table below shows how these types of heat exchangers differ in construction and operation:

Heat Exchanger Type | Construction Description | Operation Description |

|---|---|---|

Shell and Tube | Series of tubes inside a cylindrical shell | One fluid flows through tubes, another flows around them for heat transfer |

Plate | Thin, corrugated plates | Fluids pass through alternate plates for efficient heat transfer |

Spiral | Concentric spiral channels | Fluids flow in opposite directions, boosting heat transfer efficiency |

Double Tube | Two concentric pipes | One fluid in inner pipe, another in outer space, allowing heat transfer |

Air-Cooled | Uses air to cool fluids | Air passes over surface, cooling fluid inside |

Regenerative | Stores heat in a material matrix | Heat absorbed and released in cycles, improving energy efficiency |

Tube in Tube | Two tubes, one inside the other | Similar to double tube, effective fluid-to-fluid heat transfer |

People often choose a type based on the fluid, temperature, and space available. Some types of heat exchangers work better for thick fluids, while others handle high pressure or large volumes. The right choice can improve energy efficiency and make heat transfer more reliable.

Tip: Understanding the main types of heat exchangers helps users pick the best solution for their needs.

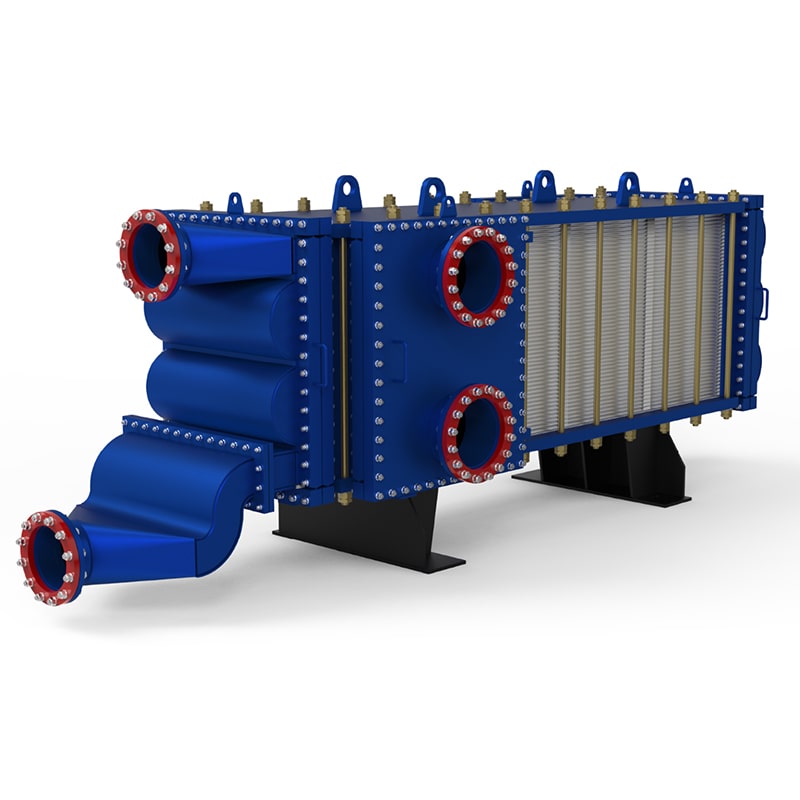

Shell and Tube Heat Exchangers

Operation and Design

Shell and tube heat exchangers stand out as one of the most popular choices in many industries. Their design looks simple, but it works very well. One fluid moves through a bundle of tubes, while another fluid flows around these tubes inside a larger shell. The two fluids never mix. Instead, heat transfer happens through the walls of the tubes.

Engineers often add baffles inside the shell. These baffles guide the fluid and create turbulence. This extra movement helps boost heat transfer between the fluids. The design also allows for easy cleaning and maintenance, which keeps the system running smoothly.

Here’s a quick look at the main design features and why they matter:

Design Feature | Contribution to Industrial Use |

|---|---|

Robust Construction | Strong design suitable for high pressure applications |

Efficient Heat Transfer | High heat transfer rates enhance operational efficiency |

Flexible Design Options | Various configurations and materials for diverse needs |

Advantages of Shell and Tube

Shell and tube heat exchangers offer several big advantages. Their strong construction lets them handle high pressures and very hot temperatures. This makes them perfect for tough jobs where other heat exchangers might not work as well. They can support both the tube side and the shell side under demanding conditions. Many industries choose them for processes that involve phase changes or large temperature differences.

These heat exchangers also work well in critical environments. They keep performing even when the pressure and temperature go up. That’s why so many factories and plants rely on them for reliable heat transfer.

Typical Applications

People use shell and tube heat exchangers in many places. You’ll find them in oil refineries, chemical plants, and power stations. They help cool or heat fluids in large systems. These heat exchangers also show up in HVAC systems, ships, and even food processing plants. Their flexible design means they can fit many different jobs, from cooling water to heating oil.

Tip: When a job calls for strong performance and efficient heat transfer, shell and tube heat exchangers often lead the way.

Plate Heat Exchangers

Plate and Frame Features

Plate heat exchangers use a series of thin plates to move heat between fluids. Each plate creates a large surface area, which helps fluids exchange heat quickly. The design allows engineers to adjust the number and type of plates for different jobs. Some plates are thicker for strength and durability, while others are thinner for better rates of heat transfer. Plates with a herringbone pattern boost turbulence and reduce fouling. This pattern also makes the unit stronger and easier to clean.

Feature | Description |

|---|---|

Thicker plates | Provide higher mechanical strength and longevity, suitable for corrosive fluids and high pressure. |

Thinner plates | Offer more efficient heat transfer and lower manufacturing costs, ideal for non-corrosive fluids. |

Plates with large heat exchange area | Promote higher heat transfer rates and reduce fouling, suitable for rapid heat exchange applications. |

Plates with small heat exchange area | Lower cost and easier maintenance, suitable for space-constrained installations. |

Herringbone corrugation | Enhances turbulence, reduces fouling, provides high mechanical strength, and allows design optimization. |

Wide Gap Welded Plate Heat Exchanger

Shanghai Plate Heat Exchanger offers the Wide Gap Welded Plate Heat Exchanger as a leading solution for tough industrial needs. This product stands out because it uses wide flow channels that prevent clogging, even when fluids contain solids or fibers. The fully welded, gasket-free construction handles high pressure and temperature with ease. Workers can open the unit from all sides, making cleaning and inspection simple. The vertical design saves space and reduces pressure drops, which means greater efficiency in tight areas.

Feature | Wide Gap Welded Plate Heat Exchanger | Traditional Plate Heat Exchanger |

|---|---|---|

Designed for | High solids and fiber content | Cleaner fluids |

Flow channel design | Wide flow channels for anti-clogging | Standard flow channels |

Application suitability | Slurries and high-concentration fluids | General applications |

Cleaning advantage | Easy-to-clean, detachable design | Not always easy to clean |

Shanghai Plate Heat Exchanger’s product meets strict industry standards, including cGMP, FDA, and EMEA certifications. These approvals show that the unit works well in chemical, food, and pharmaceutical industries.

Benefits of Plate Heat Exchangers

Plate heat exchangers deliver high thermal efficiency, which lowers energy use and costs. Their design allows for easy disassembly, so cleaning takes less time compared to tube heat exchangers. Maintenance is simple, and workers can restore performance quickly by cleaning the plates. The strong turbulence inside the channels helps prevent scale buildup and keeps heat transfer rates high.

Benefit | Description |

|---|---|

High thermal efficiency | Lowers energy consumption |

Reduced maintenance needs | No gaskets extend service life |

Suitability for challenging fluids | Suitable for high-pressure and high-temperature applications |

Easy disassembly for cleaning

Quick cleaning process compared to tube heat exchangers

Simplified maintenance with plate cleaning or CIP

Plate heat exchangers recover waste heat fully, which supports energy savings. Their high shear velocities stop scale from forming, and cleaning restores performance with minimal downtime. These features make them a smart choice for industries that need greater efficiency and reliable heat transfer.

Tip: Plate heat exchangers work best when users want better rates of heat transfer and easy maintenance.

Spiral Heat Exchangers

Spiral Design

Spiral heat exchangers use a unique spiral-shaped flow path. This design stands out from other heat exchangers. The spiral channels guide fluids in a continuous curve, which helps boost heat transfer. The path keeps fluids moving and reduces spots where flow might slow down. These areas, called dead zones, can cause problems in other designs. The spiral shape also helps the unit clean itself as fluids move through. This makes spiral heat exchangers a smart choice for fluids that are thick or tend to clog equipment.

Spiral heat exchangers feature a continuous spiral-shaped flow path, enhancing heat transfer efficiency.

The design minimizes dead zones and promotes self-cleaning, making them effective for viscous and fouling fluids.

The counter-current flow pattern improves thermal efficiency, while the absence of gaskets increases durability and maintenance ease.

Key Benefits

Spiral heat exchangers offer several important advantages. Their design maximizes the temperature difference between fluids, which leads to better heat transfer. The spiral flow creates turbulence, so deposits do not build up easily. This means less clogging and fewer shutdowns for cleaning. Spiral heat exchangers work well with many types of fluids and in different industries. They also save space because the spiral shape packs a lot of heat transfer area into a small unit. The self-cleaning action and strong materials mean less maintenance and a longer life. Many companies find that these units help lower costs over time.

Enhanced heat transfer efficiency due to the spiral flow path.

Superior fouling resistance because turbulence reduces deposit formation.

Versatility in applications, making them suitable for many industries.

Compact and space-saving design with a high heat transfer surface area.

Low maintenance and long life thanks to self-cleaning and durable construction.

Cost-effective operation from high efficiency and reduced maintenance needs.

Tip: Spiral heat exchangers are a great option when fluids are sticky, dirty, or likely to cause clogs.

Best Use Cases

Spiral heat exchangers shine in several industries. Their design helps them handle tough jobs where other heat exchangers might struggle. The table below shows some of the best use cases and the advantages they bring:

Use Case | Advantages |

|---|---|

Chemical Processing | High-efficiency heat exchange, reliable under harsh conditions |

Food Processing | Enhanced heat transfer efficiency, minimizes fouling |

Energy Recovery Systems | Compact size, saves operational space compared to traditional exchangers |

Many factories use spiral heat exchangers for chemical processing because they can handle harsh fluids and keep running smoothly. Food plants like them because they resist fouling and keep heat transfer rates high. Energy recovery systems benefit from their small size and strong performance.

Air Cooled Heat Exchangers

How Air Cooled Exchangers Work

Air cooled heat exchangers use the power of air to cool fluids without needing water. They rely on a simple but effective process. Here’s how they work:

The hot process fluid enters the tubes or plates inside the exchanger.

The fluid starts to transfer heat to the metal surfaces.

Fans pull in outside air and move it across the heated surfaces.

The air absorbs the heat, cooling the fluid inside.

The system pushes the warm air out through vents.

Sensors check the temperature and adjust the fans to keep cooling steady.

The cooled fluid leaves the exchanger, ready for the next step.

This process keeps the system running smoothly and helps control temperatures in many industries.

Air Cooled Advantages

Air cooled heat exchangers offer several important benefits. They do not need water for cooling, which makes them perfect for places where water is scarce or expensive. These units also help companies save money and protect the environment by reducing water use. People can install them almost anywhere because they do not need a water supply. The design makes installation and maintenance easy, so workers spend less time on setup and repairs. Many models are modular and scalable, which means they can grow with a company’s needs.

Tip: Air cooled heat exchangers provide a sustainable solution for industries that want to lower water costs and simplify maintenance.

Application Scenarios

Air cooled heat exchangers fit well in many situations. They work best in areas with limited water resources or strict water regulations. Factories in dry regions often choose these units to avoid high water bills. Power plants and refineries use them to cool process fluids without adding extra water systems. Data centers and HVAC systems also rely on air cooled designs to keep equipment safe and efficient.

Application Area | Why Air Cooled Works Well |

|---|---|

Dry Climates | No water needed for heat transfer |

Remote Locations | Easy installation, no water supply needed |

Industrial Plants | Reduces water use and maintenance |

Data Centers | Keeps electronics cool and reliable |

Air cooled heat exchangers help many industries achieve reliable heat transfer while saving water and energy.

Double Tube and Tube in Tube Heat Exchangers

Double Tube Design

Double tube heat exchangers use two concentric tubes. One fluid flows through the inner tube, while another moves in the space between the tubes. This setup keeps the fluids separate and allows for efficient heat transfer. Engineers often choose double tube heat exchangers for jobs that need high reliability and safety. The design includes two parallel tube sheets at both ends of the tube bundle. These tube sheets create a double sealing barrier, which helps prevent leaks. If a leak happens, the fluid stays in the space between the tube sheets. Workers can spot leaks quickly because the space is vented for easy detection. Each tube is secured by mechanical expansion or welding, which boosts durability and reliability.

Feature | Description |

|---|---|

Tube Sheets | Two parallel tube sheets at both ends, creating a double sealing barrier. |

Leakage Prevention | Leaking fluid stays between tube sheets, preventing mixing. |

Detection Mechanism | Vented space allows rapid leak detection. |

Structural Integrity | Tubes secured by expansion or welding for strength. |

Tube in Tube Features

Tube in tube heat exchangers look similar but have some differences. They use one tube inside another, with fluids flowing in opposite directions. This counterflow design increases heat transfer efficiency. Tube in tube heat exchangers work well with fluids that have high viscosity or contain particles. The smooth inner surfaces help prevent clogging and make cleaning easier. Many industries use tube in tube heat exchangers for heating or cooling thick liquids, slurries, or fluids with solids.

Unique Benefits

Both double tube and tube in tube heat exchangers offer unique benefits. Double tube heat exchangers provide extra safety because of their double sealing and leak detection features. They suit applications where fluid mixing must not happen, such as in chemical or pharmaceutical plants. Tube in tube heat exchangers handle tough fluids and work in harsh environments. Their design supports efficient heat transfer, even with challenging fluids. These heat exchangers fit jobs that need reliable performance and easy maintenance.

Tip: When choosing between double tube and tube in tube heat exchangers, consider the fluid type and the need for leak prevention or easy cleaning.

Regenerative Heat Exchangers

Regenerative Operation

Regenerative heat exchangers work by storing heat from one stream and then releasing it to another. They use special materials that absorb heat from hot fluids and give it back to cooler fluids later. This process happens in cycles. The exchanger switches between absorbing and releasing heat. The design helps maximize heat transfer between the two streams. People often see these exchangers in systems where saving energy matters. The cycle keeps the heat moving and makes the process more efficient.

Did you know? Regenerative heat exchangers can recover more heat than many other designs because they use thermal storage materials.

Special Advantages

Regenerative heat exchangers stand out for their ability to recover energy. They use thermal storage materials to absorb heat from waste streams and release it where it is needed. This method allows them to reach higher heat recovery rates than continuous heat exchangers. The process boosts energy efficiency and helps companies lower costs. These exchangers also improve heat transfer by keeping the temperature difference high during each cycle. The design reduces energy loss and supports sustainable operations.

Advantage | Description |

|---|---|

High energy recovery | Stores and reuses heat from waste streams |

Improved efficiency | Maximizes heat transfer during each cycle |

Lower operational costs | Reduces energy consumption |

Supports sustainability | Helps meet energy-saving goals |

Common Applications

Regenerative heat exchangers show up in many industries. Their ability to recover heat and improve efficiency makes them popular in places where energy savings matter.

Solar and biomass energy applications

Chemical, power, and manufacturing sectors

Pharmaceutical and data center sectors

HVAC Systems

Industrial Processes

Energy Generation

Marine Applications

Automotive

People use regenerative heat exchangers in solar and biomass systems to capture and reuse heat. Chemical plants and power stations rely on them for efficient heat transfer. Data centers and HVAC systems benefit from their energy-saving features. Marine and automotive industries also use these exchangers to improve performance and reduce waste.

Tip: Regenerative heat exchangers help companies save energy and money while supporting cleaner operations.

Comparison Table of Thermal Exchanger Types

Quick Reference of Benefits

Choosing the right heat exchangers can feel tricky. Each type brings its own strengths to the table. People often look at how well a unit handles heat transfer, how easy it is to maintain, and what it costs over time. Let’s break down the main types and see how they stack up.

Looking for a quick way to compare? Check out the tables below for a snapshot of what each exchanger offers.

Key Performance Metrics for Thermal Exchangers

Type | Heat Duty | Heat Transfer Coefficient | Fouling Resistance | Mean Temperature Difference | Heat Transfer Area |

|---|---|---|---|---|---|

Shell and Tube | High | Moderate | Moderate | High | Large |

Plate and Frame | High | Superior | Good | High | Compact |

Spiral | Moderate | Good | Excellent | Moderate | Compact |

Air Cooled | Moderate | Moderate | Good | Moderate | Large |

Double Tube | Moderate | Good | Good | Moderate | Moderate |

Tube in Tube | Moderate | Good | Good | Moderate | Moderate |

Regenerative | High | Superior | Excellent | High | Large |

Quick Reference Table: Efficiency, Maintenance, and Cost

Type | Efficiency | Maintenance | Cost |

|---|---|---|---|

Plate and Frame | Superior heat transfer | Simple and quick | Lower lifecycle cost |

Shell and Tube | Good for high pressure | More effort required | Lower upfront, higher over time |

Spiral | Good for fouling fluids | Low maintenance | Moderate |

Air Cooled | Water-saving | Easy access | Moderate |

Double Tube | Reliable leak prevention | Easy detection | Moderate |

Tube in Tube | Handles tough fluids | Easy cleaning | Moderate |

Regenerative | Excellent energy recovery | Low maintenance | Higher initial, saves energy |

Plate and frame heat exchangers stand out for their compact size and high heat transfer efficiency.

Shell and tube units work best in high-pressure jobs but need more space and maintenance.

Spiral designs resist fouling and keep heat transfer rates steady.

Air cooled models save water and offer easy access for cleaning.

Double tube and tube in tube types provide reliable performance with simple maintenance.

Regenerative exchangers help companies recover energy and lower costs.

Tip: When comparing options, focus on heat transfer efficiency, ease of cleaning, and long-term cost. The right choice depends on your process needs and available space.

Choosing the Right Thermal Exchanger

Selection Factors

Selecting the right thermal exchanger can feel overwhelming, but breaking it down makes the process easier. Every application has its own needs, so people should look at a few key factors before making a choice. The type of fluid, the temperature range, and the available space all play a big role. Some fluids need special materials to prevent corrosion, while others require strong construction to handle high pressure.

Here’s a table that highlights the main factors to consider when picking a thermal exchanger:

Factor | Importance |

|---|---|

Thermal Conductivity | Faster and more efficient heat transfer between fluids. |

Corrosion Resistance | Essential for long life, especially with harsh or corrosive fluids. |

Mechanical Strength | Needed for high pressures and temperatures; resists stress and fatigue. |

Cost and Availability | Balances performance with budget; some materials cost more but last longer. |

Ease of Fabrication | Affects long-term maintenance and repair costs. |

Weight | Important for mobile or space-limited setups; less critical in stationary systems. |

People should also think about how easy it is to clean and maintain the thermal exchanger. For example, plate heat exchangers often allow for quick cleaning, which saves time and money. The right choice will depend on the specific job, the type of fluid, and the space available.

Tip: Always match the thermal exchanger to the toughest demands of your process, not just the average conditions.

Shanghai Plate Heat Exchanger Solutions

Shanghai Plate Heat Exchanger offers a wide range of solutions for different industries. Their products cover everything from standard plate heat exchangers to advanced welded designs. They build each thermal exchanger to deliver reliable heat transfer and long service life.

Here’s a quick look at their product range and where each one fits best:

Product Type | Applications |

|---|---|

Plate Heat Exchangers | Chemical, marine, HVAC, and energy sectors |

Leak-proof performance and durability | |

Brazed Plate Heat Exchangers | Aggressive media and high-pressure needs |

M15B Series Plate Heat Exchanger | Marine environments, seawater cooling, LNG systems |

Shanghai Plate Heat Exchanger helps customers choose the right thermal exchanger for their needs. Their team understands the challenges of heat transfer in tough environments. They recommend solutions that balance efficiency, durability, and cost. With their expertise, companies can find the best fit for any application.

Heat exchangers come in many forms, each with its own strengths. Matching the right thermal exchanger to the job brings real advantages:

Maintaining optimal temperatures keeps machinery safe.

Improving energy efficiency saves resources.

Extending equipment lifespan protects investments.

Enhancing process performance boosts product quality.

Shanghai Plate Heat Exchanger offers expert guidance and advanced solutions. Their team supports clients from design to installation.

Service Type | Description |

|---|---|

Custom Design Capabilities | SHPHE collaborates with clients to create tailored PCHE solutions for specific needs. |

Technical Support | Full support from design and simulation to manufacturing is provided. |

Customer Service | Guidance is offered from initial inquiry through installation and operation. |

Contact Information | Ying Qiu, Email: info@shphe.com, Phone: +86 15201818405, Address: No. 99, Shanning Road, Jinshan, 201508, Shanghai, China |

FAQ

What is the main purpose of a heat exchanger?

A heat exchanger moves heat from one fluid to another without mixing them. This helps control temperatures in machines, factories, and homes.

How does someone choose the right heat exchanger type?

They should look at the fluid, temperature, and space. Each type works best for certain jobs. Experts at Shanghai Plate Heat Exchanger can help with the choice.

Can plate heat exchangers handle dirty or thick fluids?

Yes! Wide Gap Welded Plate Heat Exchangers from Shanghai Plate Heat Exchanger work well with fluids that have solids or fibers. The wide channels prevent clogging.

Why do industries prefer welded plate heat exchangers?

Industries like these exchangers because they handle high pressure and temperature. The welded design means fewer leaks and less maintenance.

How often should someone clean a heat exchanger?

Cleaning depends on the fluid and use. Many plate heat exchangers allow for easy cleaning. Regular checks keep the system running well.