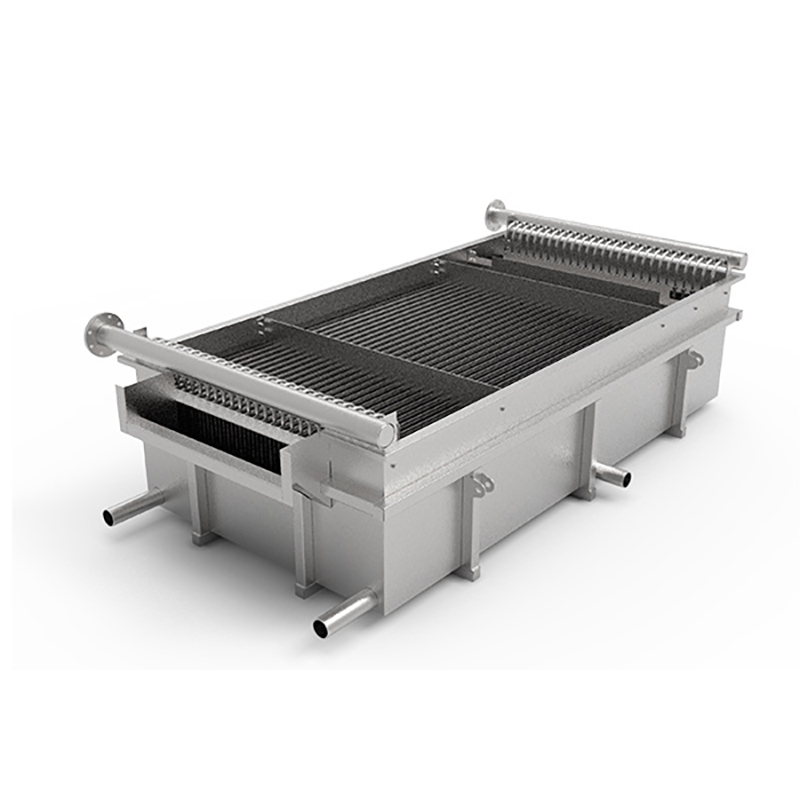

How to Choose the Right OEM Pillow Plate Supplier for Your Project

OEM Pillow Plate Supplier Criteria

Experience and Industry Knowledge

Selecting an OEM pillow plate supplier begins with evaluating their experience and industry knowledge. Suppliers with a long history in the field understand the complexities of heat exchange technology. They can anticipate challenges and deliver solutions that meet demanding project requirements. A supplier’s expertise ensures that every stage, from design to manufacturing, aligns with industry standards and client expectations.

Shanghai Heat Transfer (shphe) stands out as a supplier with proven expertise and a strong track record. Their team has worked with a wide range of industries, including food processing, chemical manufacturing, and environmental protection. This broad experience allows them to address unique project needs and provide valuable guidance throughout the process. When reviewing suppliers, companies should use criteria such as years in business, project portfolio, and client testimonials to assess expertise and reliability.

Material Selection and Thickness

Material selection and plate thickness play a critical role in the performance and durability of pillow plate heat exchangers. The right combination of material and thickness ensures optimal heat transfer, mechanical strength, and resistance to pressure. Suppliers should offer a variety of materials and thickness options to match the specific requirements of each application.

Common materials include:

DC04

304

304L

316L

316Ti

318LN

904L

254 SMO

The most frequently used thicknesses are:

0.8 mm

1.0 mm

1.5 mm

2.0 mm

3.0 mm

Material | Thickness Range | Unit |

|---|---|---|

Mild Steel | 0.80 - 20.00 | mm/inch |

Stainless Steel | 0.80 - 20.00 | mm/inch |

Uniform thickness is essential for proper deformation during hydroforming, which impacts the final product’s efficiency and reliability. Thinner plates may deform unevenly, leading to performance issues. Optimizing thickness reduces weight while maintaining thermal and mechanical performance. This approach enhances efficiency and ensures the pillow plate can withstand high temperatures and pressures.

Customization Capabilities

Customization capabilities set leading suppliers apart in the pillow plate market. Not all suppliers offer full customization, but those who do can tailor dimensions, materials, and design features to fit unique project needs. This flexibility allows for special shapes, sizes, and material choices, such as stainless steel or carbon steel, to match specific operational requirements.

The ability to customize pillow plate heat exchangers leads to better project outcomes and higher client satisfaction. Custom designs improve heat transfer efficiency and ensure compliance with industry standards. Companies like shphe provide extensive customization options, supporting clients in achieving optimal performance for their applications.

When choosing a supplier, companies should include customization capabilities as a key criteria. Suppliers who demonstrate expertise in engineering flexible solutions can adapt to changing project demands and deliver superior results.

Quality and Certifications

Quality Standards for Pillow Plate Heat Exchangers

Quality plays a central role in the performance and safety of pillow plate heat exchangers. Manufacturers must implement strict quality control measures throughout the production process. These measures include material inspection, precise welding, and thorough pressure testing. Consistent quality ensures that pillow plate heat exchangers deliver reliable thermal performance and withstand demanding operating conditions.

Shphe has established a reputation for maintaining high quality standards. The company uses advanced manufacturing techniques and rigorous quality control measures to guarantee product consistency. Each pillow plate heat exchanger undergoes detailed inspection before shipment. This approach reduces the risk of defects and increases the lifespan of the equipment.

Key Certifications (ASME, CE, etc.)

Certifications validate the safety and reliability of pillow plate heat exchangers in global markets. Regulatory bodies require manufacturers to comply with recognized standards. These certifications confirm that products meet strict design, construction, and testing requirements.

The following table summarizes the most frequently required certifications for pillow plate heat exchangers:

Certification | Description |

|---|---|

ASME | International Boiler and Pressure Vessel Code, applicable to heat exchangers under ASME VIII. |

PD500 | Standard for unfired, fusion-welded pressure vessels. |

EN13445 | European pressure vessel standards covering various aspects of design and manufacturing. |

TEMA | Tubular Exchanger Manufacturers Association standards for heat exchangers. |

API | American Petroleum Institute standards relevant to heat exchangers. |

ISO | International Organization for Standardization standards applicable to various manufacturing processes. |

Certifications such as ASME and CE enhance the marketability of pillow plate heat exchangers. These certifications ensure compliance with international safety and performance standards. Regulatory frameworks govern the design, construction, and maintenance of thermal equipment. Products with these certifications gain acceptance in regulated industries, including food processing, pharmaceuticals, and chemical manufacturing.

Shphe holds multiple certifications, including ASME and CE. The company’s commitment to certification demonstrates its dedication to quality and safety. This focus allows shphe to serve clients in highly regulated sectors worldwide.

Evaluation Criteria for Product Reliability

Evaluation of product reliability involves several key factors. Buyers should consider the following evaluation criteria when selecting pillow plate heat exchangers:

Consistency in manufacturing processes

Adherence to international standards and certifications

Comprehensive quality control measures

Proven track record of performance in similar applications

Availability of technical documentation and test reports

Reliable pillow plate heat exchangers maintain stable performance over time. They resist corrosion, deformation, and pressure fluctuations. Shphe provides detailed technical support and documentation for every product. This transparency helps clients verify product reliability before installation.

Tip: Always request documentation of quality control measures and certifications from your supplier. This step ensures that the pillow plate heat exchangers meet your project’s requirements and industry regulations.

By focusing on quality, certifications, and clear evaluation criteria, companies can select pillow plate heat exchangers that deliver long-term value and dependable performance.

Customization and Innovation

Engineering Flexibility

Engineering flexibility allows pillow plate suppliers to meet a wide range of project requirements. Clients value the ability to choose from different plate types and designs. The following table shows common options and their features:

Type | Features | Applications |

|---|---|---|

Single Embossed Pillow | Highly flexible design, compact size | Heating and cooling applications |

Double Embossed Pillow | Customizable, supports various industrial needs | Industrial heat exchange |

Immersion Pillow Plate | Easy maintenance, effective for high-viscosity liquids | Contaminated liquid heating/cooling |

Tailored designs, ensures no heat tint, sanitary properties | Food and pharmaceutical applications |

Suppliers like shphe use advanced design software and rapid prototyping to deliver custom solutions quickly. This engineering flexibility helps reduce project timelines and ensures that each pillow plate fits the client’s unique process.

Technological Advancements

Recent technological innovation has transformed the pillow plate industry. Manufacturers now use advanced laser welding to create precise dimples and strong seams. Industry 4.0 integration allows real-time quality monitoring during production. These improvements increase efficiency and product quality. The use of computational fluid dynamics (CFD) simulations helps optimize heat transfer and fluid flow. Some manufacturers have adopted nanofluids and microencapsulated phase change materials to boost heat transfer rates. The shift from manual production to automatic laser welding machines has made manufacturing faster and more consistent. These advancements show how innovation drives better performance and reliability.

Application Versatility

Pillow plate heat exchangers serve many industries because of their versatility. The table below highlights key sectors and benefits:

Industry Sector | Applications | Benefits |

|---|---|---|

Processing, preservation | Improved quality, lower costs | |

Chemical | Manufacturing processes | Higher energy efficiency |

Pharmaceutical | Product integrity during processing | Compliance with strict standards |

Energy | Thermal management, energy recovery | Cost savings, energy conservation |

Commercial | HVAC, refrigeration, kitchens | Better temperature control |

Residential | Heating, water heating, heat recovery | Sustainable living, energy savings |

Suppliers like shphe use customization and innovation to tailor pillow plate solutions for each industry. They select high-grade materials and advanced construction techniques to meet strict hygiene and performance standards. This approach ensures that every client receives a product designed for their specific needs.

Pricing, Support, and Supply Chain

Transparent Pricing Criteria

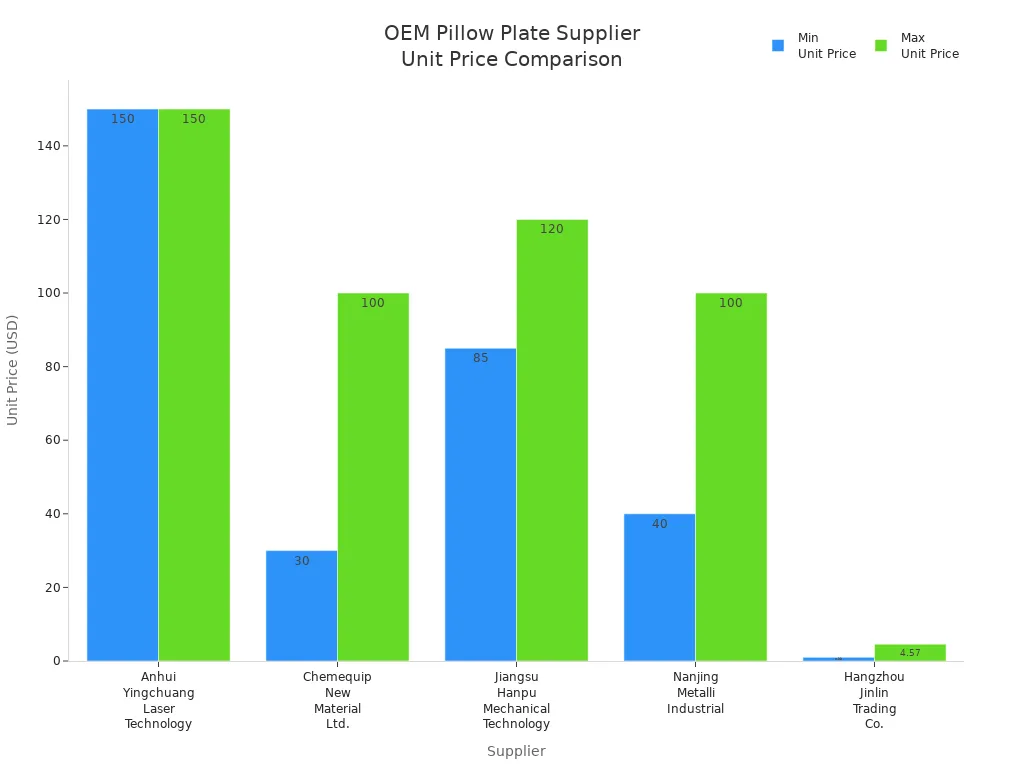

Pricing transparency helps buyers compare options and make informed decisions. Most oem metal fabrication shop suppliers use clear pricing models based on unit price, minimum order quantity, and service offerings. The table below shows how leading suppliers structure their prices and strengths:

Supplier | Unit Price Range (USD) | MOQ | Key Strengths |

|---|---|---|---|

Anhui Yingchuang Laser Technology | $150 | 1–20 pcs | 100% on-time delivery, 50% reorder rate, fast response |

Chemequip New Material Ltd. | $30–100 | 1 set | Low price, broad customization |

Jiangsu Hanpu Mechanical Technology | $85–120 | 10 pcs | Titanium options, scalable batches |

Nanjing Metalli Industrial | $40–100 | 1 piece | Low MOQ, laser welding focus |

Hangzhou Jinlin Trading Co., Ltd. | $0.99–4.57 | 20 pieces | Ultra-low cost, packaging-integrated uses |

Price differences often reflect variations in performance, customization, and support. High-performance heat exchangers from reputable suppliers like shphe may cost more but deliver greater energy efficiency and long-term value. Buyers should review the supplier’s portfolio and reputation to understand what is included in the price.

After-Sales Support

Strong after-sales support ensures that clients receive help throughout the product’s life cycle. Leading oem metal fabrication shop suppliers offer:

Technical consultations for product questions

Installation guidance for proper setup

Troubleshooting assistance for operational issues

Warranty management systems and easy claim processes improve customer service and satisfaction. These services reduce operational costs and build loyalty. Shphe provides high-quality products and full support, which includes technical expertise and responsive customer service. This approach helps clients achieve reliable performance and energy-efficient solutions.

Supply Chain Reliability

Supply chain reliability impacts project timelines and costs. Reliable oem metal fabrication shop suppliers use advanced inventory management and real-time tracking to maintain optimal stock levels. They synchronize production schedules with delivery needs and communicate closely with clients. This process supports on-time delivery and consistent performance.

Disruptions in the supply chain can cause delays and increase costs. Suppliers with just-in-time capabilities and strong planning systems help clients avoid these risks. Shphe’s experience and commitment to reliability ensure that custom-engineered heat exchangers arrive on schedule, supporting energy efficiency and project success.

Tip: Always ask about supply chain practices and after-sales support when choosing an oem metal fabrication shop. These factors play a key role in long-term performance and customer service.

Selecting the right OEM pillow plate supplier involves careful evaluation. Buyers should focus on experience, quality, customization, pricing, support, and reliability. The table below highlights important steps for supplier selection:

Description | |

|---|---|

Reputation | Review case studies and customer references. |

Technical Capabilities | Check equipment, experience, and quality assurance. |

Post-Manufacturing Support | Assess after-sales service and product development support. |

Scalability | Confirm the supplier can meet future needs. |

Communication | Ensure clear and effective communication. |

A checklist helps compare suppliers. For trusted results, many choose shphe for proven expertise and support.

FAQ

What makes oem pillow plate exchangers different from traditional metal heat exchangers?

Oem pillow plate exchangers use a unique internal structure. This design increases heat transfer efficiency. The metal plates have embossed patterns that create fluid channels. These exchangers handle high pressure and temperature. Many industries choose oem pillow plate solutions for better performance and durability.

How does shphe ensure quality in oem pillow plate metal exchangers?

Shphe uses advanced manufacturing for oem pillow plate exchangers. The company inspects every metal component. They follow strict quality standards. Certifications like ASME and CE support their process. Shphe provides reliable oem solutions for many industries.

Can oem pillow plate exchangers be customized for different metal applications?

Yes. Oem pillow plate exchangers offer many customization options. Clients can select metal type, thickness, and size. Shphe engineers design solutions for unique needs. These exchangers fit food, chemical, and energy industries. Customization improves efficiency and safety.

What after-sales support do oem suppliers like shphe provide for metal exchangers?

Oem suppliers such as shphe offer technical support for metal exchangers. They help with installation and troubleshooting. Clients receive guidance on maintenance. This support ensures oem pillow plate solutions work well over time. Reliable service builds trust with customers.

Why do industries prefer oem pillow plate solutions for heat exchangers?

Industries prefer oem pillow plate solutions because these exchangers save energy and reduce costs. The metal design resists corrosion and deformation. Oem suppliers like shphe deliver products that meet strict standards. These solutions improve process safety and reliability.