How different heat exchanger types are applied across major industries

Major industries use different heat exchanger types for heating and cooling. Shell and tube heat exchangers are the most common in 2024. Plate heat exchangers are becoming more popular because they are small and work well. Shanghai Heat Transfer is a top company for plate heat exchangers. They have many products and smart solutions. Plate heat exchangers make up 42% of all units used. This shows they are liked in many fields. New heat exchanger designs help with hard jobs in oil and gas, chemical plants, and power stations. Important certifications like ASME, ISO 9001, and TEMA keep things safe and working well.

Heat exchanger certifications help companies work safely and well.

Type of Heat Exchanger | Market Share (%) |

|---|---|

Shell and Tube | Most common in 2024 |

HVAC and Refrigeration Industries

Heating, ventilation, air conditioning, and refrigeration systems are important. They help keep buildings safe and comfortable. These systems use different heat exchangers to control temperature. Heat exchangers also help save energy. Each type of exchanger has special features. These features make them good for certain jobs. Companies like Shanghai Heat Transfer make advanced solutions. They help with climate control in big and small buildings.

Plate Heat Exchanger Types for Climate Control

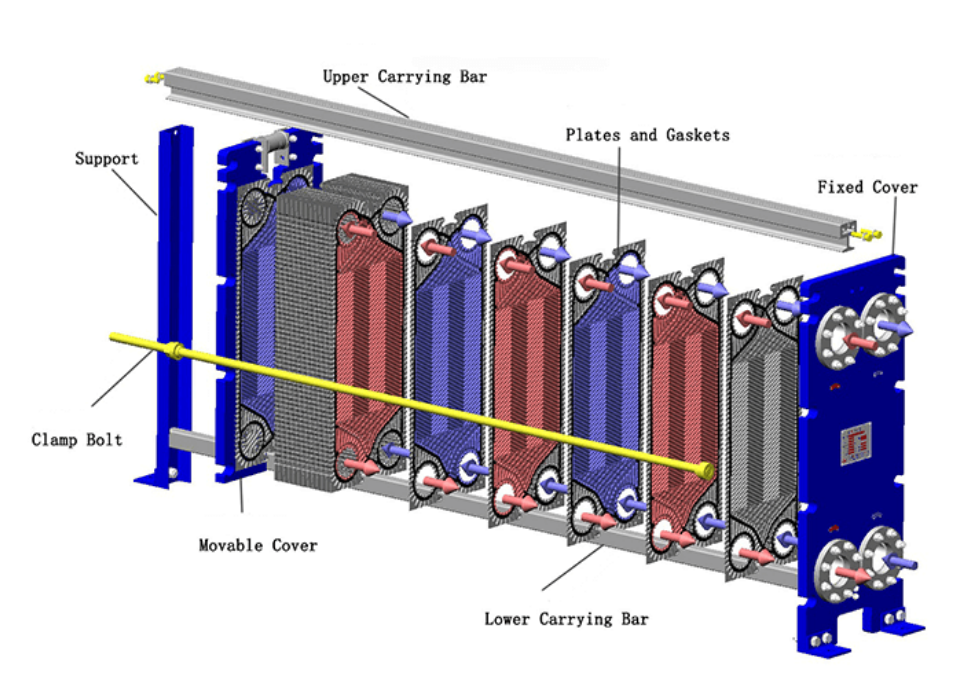

Plate heat exchangers help control temperature in many systems. They use thin plates to move heat between fluids. This design lets heat move quickly. It also saves space. Many industries pick plate heat exchangers for these reasons:

They save energy by reusing heat.

They lower costs by using less energy.

They help equipment work better.

They help the environment by cutting pollution.

They keep equipment safe from breaking.

Shanghai Heat Transfer makes plate heat exchangers for climate control. Their products include the Gasketed Plate Heat Exchanger and HT-Bloc Welded Plate Heat Exchanger. These exchangers help with both heating and cooling. They recover and reuse heat energy. This makes processes work better and use less fuel. Plate heat exchangers also cut fuel use and lower costs. They help the environment by making less pollution. Many buildings and factories use these exchangers. They keep temperatures steady and save energy.

Finned-Tube Exchanger Types in Air Conditioning

Finned-tube heat exchangers are used in air conditioning. They have metal fins on tubes. The fins make more surface area for heat to move. This design helps heat move fast between air and fluids. Finned-tube exchangers make air conditioning systems work better.

A new study showed finned-tube exchangers can make systems over 25% more efficient. The heat transfer rate got almost five times better after changes. The performance index, which compares heat transfer to pumping power, got almost three times better. This means air conditioning with finned-tube exchangers uses less energy. It also cools better. Many big buildings use these exchangers. Offices and shopping centers use them to keep air cool and fresh.

Shell-and-Tube Heat Exchanger Types for Industrial Cooling

Shell-and-tube heat exchangers are used for cooling in big systems. They have a shell with tubes inside. One fluid goes through the tubes. Another fluid moves around the tubes in the shell. This setup lets heat move well and safely, even in large systems.

The table below shows where shell-and-tube exchangers are used:

Industry | Application Description |

|---|---|

Power Plants | Keep cooling water systems working for turbines and generators. |

Chemical and Petrochemical | Control heat in production to keep reactions safe and products good. |

Oil and Gas | Cool oils and gas streams for safe work in tough places. |

HVAC and Refrigeration | Control coolant temperatures in big air conditioning and refrigeration systems. |

Manufacturing and Metal Processing | Keep equipment working and products good by stopping too much heat. |

In HVAC and refrigeration, shell-and-tube exchangers control coolant temperatures in big systems. They are used in chilled water systems to cool water for air handlers. They are also used in hot water boilers for heating. Heat recovery units use them to reuse waste heat. These uses help equipment work well and save energy.

Note: Picking the right heat exchanger for each job helps things work better, cost less, and stay safe.

Shanghai Heat Transfer has many heat exchanger types for HVAC and refrigeration. Their products work in small buildings and big factories. With smart designs and certified products, they help industries get good heating and cooling while saving energy.

Power Generation and Energy Industries

Heat exchanger types are very important in power and energy. These systems need good heat control and energy movement. Different exchangers help manage heat and make things work better. They also keep everything safe.

Shell-and-Tube Heat Exchanger Types in Power Plants

Shell-and-tube exchangers are used in many power plants. They control heat in steam cycles and cool other systems. They also turn steam back into water. The table below shows how these exchangers help in power plants:

Heat Exchanger Type | Application in Power Generation |

|---|---|

Steam Power Plant | Controls steam temperature and pressure. Turns steam into water for reuse. |

Gas and Coal-Fired | Takes heat from flue gas, warms feedwater, and cools other systems. |

Nuclear Power | Moves heat from radioactive coolant to safe loops. Uses leak-proof designs. |

Shanghai Heat Transfer makes shell-and-tube exchangers for tough jobs. Their products are safe and high quality. They work well for heating and cooling in power plants.

Plate Heat Exchanger Types for Renewable Energy

Plate heat exchangers are used in renewable energy. In geothermal plants, they move heat from underground fluids to working fluids. Solar thermal systems use small plate exchangers to get heat from the sun. These designs save space and use energy well. Special materials stop rust in salty geothermal places. By saving heat, these exchangers help lower pollution from energy systems.

Plate exchangers take and move heat in geothermal plants.

Solar thermal systems use small units to get more heat.

Special materials help them last a long time.

Plate exchangers cut energy waste and help clean energy.

Shanghai Heat Transfer’s plate exchangers are made for renewable energy. Their products work well and last in hard places.

Air-Cooled Exchanger Types in Gas Turbines

Air-cooled exchangers help gas turbines work well in hot weather. These exchangers are cheap and stop power loss when it is hot. Evaporative cooling can make air up to 30°F cooler. This helps turbines burn fuel better and make more power. Air-cooled exchangers use less electricity than chillers and use water to cool. They also keep dust and dirt out of turbines. Cooling air below 59°F lets turbines make more power, which is good when it is hot.

Air-cooled exchangers save money and protect turbines.

They help gas turbines work well and move energy.

Shanghai Heat Transfer makes air-cooled exchangers for power plants. Their products are safe and help with heating and cooling, even in hard places.

Chemical and Petrochemical Industries

Picking the right heat exchanger is important for safety. It also helps things work well in chemical plants. Many industries use different exchangers for heating and cooling. These exchangers work in tough places. The materials and designs keep workers and equipment safe.

Plate Heat Exchanger Types for Corrosive Fluids

Plate heat exchangers are good for strong chemicals in plants. They use special alloys that do not get damaged by acids or alkalis. Some common alloys are stainless steel, nickel-based alloys, and titanium. Titanium and Hastelloy are very good for hard chemical jobs. Stainless steel with coatings costs less and still works well. Surface treatments and inhibitors make a shield on the metal. This helps the exchangers last longer. New plate designs help fluids move better and stop damage. Shanghai Heat Transfer makes special exchangers for these jobs.

Special alloys work in tough places.

Inhibitors and passivation keep surfaces safe.

Titanium, Hastelloy, and coated stainless steel are used a lot.

New plate shapes and coatings make exchangers last longer.

Shell-and-Tube Exchanger Types in Refineries

Shell-and-tube exchangers are used a lot in refineries. They are strong and can handle high pressure and heat. These exchangers move heat well and do not rust easily. This is important for plants that run all the time. Refineries use them to save heat and move heat in processes. Safety rules like ASME, TEMA, and API 660 keep things safe in hard jobs. Shanghai Heat Transfer makes exchangers that meet these rules.

Material | Key Features | Typical Applications |

|---|---|---|

Inconel Alloys | Handles high heat | Petroleum refineries |

Duplex Stainless Steel | Strong and does not rust | Chemical processing |

Coated Carbon Steel | Cheap and resists some rust | Refinery heat recovery |

Double Pipe Heat Exchanger Types for Small-Scale Chemical Processing

Chemical plants use double pipe exchangers to control heat in reactions. Good heat control keeps products safe and good. Many plants use them because they work with strong chemicals and high pressure. For example, in making polymers, these exchangers keep reactions steady. This gives better results and less waste.

Double pipe exchangers are good for small chemical jobs. They give exact heating and cooling for careful reactions. Their design makes cleaning and fixing easy. These exchangers help make products better and save energy.

Shanghai Heat Transfer makes special exchangers for all chemical jobs. Their products help plants stay safe, work well, and save energy.

Industrial Manufacturing Applications

Factories use heat exchanger types to keep machines working well. These exchangers help with heating and cooling in many jobs. Shanghai Heat Transfer makes many exchangers for factories. Their products help machines, food making, and cooling.

Finned-Tube Exchanger Types for Machinery Cooling

Factories use finned-tube exchanger types to cool machines. These exchangers have metal fins that make more space for heat to move. This design helps get rid of heat fast from machines. Finned-tube exchangers fit in small spaces and work with many materials. Workers think they are easy to clean and fix, so machines last longer.

Benefit | Description |

|---|---|

More surface area means heat moves faster, so machines stay cool. | |

Compact structure and small footprint | Good for small spaces, so they do not take up much room. |

Good adaptability and flexibility | Can be changed for different jobs and materials. |

Easy to maintain and clean | Simple design makes cleaning and fixing easy, so they last longer. |

Environmental protection and energy saving | Use less energy and money, which is good for the planet. |

Factories pick finned-tube exchangers because they work well and can change for different jobs. These exchangers stop machines from getting too hot. This keeps machines safe and stops them from breaking. Cleaning and checking them often, like with eddy current tests, keeps them working well.

Plate Heat Exchanger Types in Food and Beverage Manufacturing

Food and drink factories need exchangers that are very clean. Plate heat exchanger types use thin plates to move heat between liquids. Stainless steel plates do not get dirty or rusty, so food stays safe. These exchangers use safe materials and clean designs to stop germs.

Standard Type | Description |

|---|---|

Design Considerations | Plate heat exchangers must use safe materials and clean shapes to stop germs. |

Cleaning Protocols | Clean-in-Place (CIP) systems clean them without taking them apart. |

Material Selection | Stainless steel and safe materials keep food safe when cleaning. |

Temperature Control | Monitors keep the right temperature to stop germs from growing. |

Compliance with Regulations | They follow FDA, HACCP, and ISO rules for safety and quality. |

Shanghai Heat Transfer makes plate exchangers that keep food safe and good. Their exchangers use smart designs to move heat well and stop dirt. Monitors help control temperature, so germs do not grow. These things help keep food the same and move heat well.

Air-Cooled Heat Exchanger Types for Process Equipment

Air-cooled exchanger types are important for cooling in factories. These exchangers use air to take heat away from machines. Workers use them to keep the right temperature and save energy. Air-cooled exchangers help with power, food, and chemical jobs.

Used in factories to keep the right temperature and save energy.

Needed in power plants to keep things working right.

Used in food and drink factories to move heat well.

Used in chemical plants to cool things and control heat.

Factories use air-cooled exchangers for LNG, NGL, and gas-cooling jobs. They also help with fixing refineries and big fridges. Their design uses less water and helps the environment.

Tip: Picking the right exchanger types and materials helps machines last longer and keeps products the same.

Material | Benefits |

|---|---|

Copper Alloys | Works well with seawater |

Stainless Steel | Does not get dirty or rusty, good for clean jobs |

Titanium | Does not rust in tough places |

Factories have problems like dirt, leaks, and fixing. Dirt makes heat move slower and blocks flow. Workers clean them, change gaskets, and use smart designs to fix these problems. Making more movement and less dirt helps keep them working well.

Shanghai Heat Transfer has many exchangers for factories. Their exchangers help machines last longer, keep products the same, and save energy in many jobs.

Environmental and Wastewater Industries

Plate Heat Exchanger Types for Wastewater Treatment

Plate heat exchangers are important in wastewater plants. They take heat from warm wastewater. This saves energy and money for the plant. Plate heat exchangers keep the right temperature for treatment steps. If the temperature stays steady, bad bacteria do not grow. Workers use these exchangers to make sure water treatment works every day.

Shanghai Heat Transfer makes plate heat exchangers for many uses. Their products include gasketed and welded plate types. These exchangers can handle strong fluids and hard jobs. The company’s products help plants save energy and be greener. Many plants pick Shanghai Heat Transfer because their exchangers work well.

Tip: Plate heat exchangers let plants reuse heat and use less energy.

Shell-and-Tube Exchanger Types in Environmental Protection

Shell-and-tube exchangers help protect the environment. They control heat in pollution control systems. These exchangers cool gases and liquids before filters or scrubbers. Cooling helps remove bad stuff and keeps machines safe. Shell-and-tube exchangers work with high pressure and hot fluids. They last a long time in hard places.

Shanghai Heat Transfer gives shell-and-tube exchangers for these jobs. Their products meet tough safety and quality rules. Workers use these exchangers to save energy and make less waste. The company’s exchangers help keep the environment clean and safe.

Plate and shell-and-tube exchangers:

Take heat from wastewater and process streams

Keep the best temperature for treatment

Lower costs and help the planet

Exchanger Type | Main Function | Typical Applications |

|---|---|---|

Plate Heat Exchanger | Save energy, control temperature | Wastewater treatment, recycling |

Shell-and-Tube | Cooling, pollution control | Air and water cleaning |

Shanghai Heat Transfer keeps making better heat exchangers for these industries. Their products help plants save more energy and stay clean.

Many industries use heat exchanger types for their own needs. Refrigeration needs exchangers with low pressure drop and big surface area. Power generation needs exchangers that handle high pressure and heat. Chemical processing needs exchangers that resist fouling and corrosion. The right exchanger depends on the fluids, how things run, and what is needed. Picking the best exchanger helps heat move better and saves energy. New designs use AI to keep things safe and help the planet. Shanghai Heat Transfer makes good exchangers for every job. Experts help pick the right exchanger for safe and easy heat control.

Tip: Talk to skilled manufacturers for custom solutions and future-ready jobs.

FAQ

What is a heat exchanger?

A heat exchanger moves heat from one fluid to another. It helps keep the right temperature in many places. People use it in factories, power plants, and buildings. The design lets heat move fast and keeps things safe.

Which industries use heat exchanger applications most?

Industries like power generation, chemical processing, and food making use heat exchangers a lot. These jobs need good heat control for safety and to work well.

How does a plate heat exchanger work?

A plate heat exchanger uses thin plates to move heat between fluids. The plates give a big area for heat to move. This design helps heat move fast and saves space.

What are the main benefits of using heat exchangers?

Heat exchangers save energy, cut costs, and protect machines. They help systems work well every day. Many industries pick them because they are safe and reliable.

How do companies select the right exchanger for their applications?

Companies look at what fluids they use, the temperature needed, and how big the system is. They pick an exchanger that fits their job. Experts help choose the best design for each use.