Avoiding the 5 Biggest PHE Plate Heat Exchanger Headaches

You face several common faults when working with a phe plate heat exchanger, such as leakage, corrosion, and production issues that can disrupt your operations.

Common Faults | Description |

|---|---|

Leakage | Often occurs at the weld seams of the tube plates due to erosion, cavitation, and corrosion. |

Corrosion | Internal stress from leakage can lead to further corrosion of the tubesheet weld seam. |

Production Issues | Difficulties in controlling production temperature can affect product quality. |

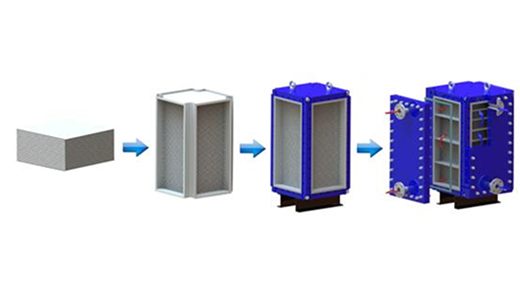

Early detection and regular maintenance extend the life and efficiency of plate heat exchangers. Shanghai Plate Heat Exchanger and the HT-Bloc Welded Plate Heat Exchanger offer advanced features, like secondary adjustment and easy gasket replacement, to help you address these common faults. You can spot underperformance by monitoring for increased pressure drop, loss of heat transfer efficiency, and fluid leakage. Regular cleaning and inspection of each plate keep your exchangers running reliably.

Fouling in PHE Plate Heat Exchangers

Identifying Fouling Issues

Fouling is the most common problem you will face with a phe plate heat exchanger. You can spot fouling early by watching for a loss of heat transfer efficiency, increased pressure drop, or higher energy bills. When fouling builds up on the plate surfaces, the exchanger cannot transfer heat as well. This means you need more energy to keep your process running. You may also notice more frequent shutdowns for cleaning or maintenance.

Tip: Regularly check for uneven temperature differences across the exchanger. This can signal early fouling before it becomes a bigger issue.

Causes of Plate Fouling

Fouling happens when unwanted materials stick to the plate surfaces inside plate heat exchangers. These materials can include minerals, sediment, algae, or even corrosion products. High temperatures, low fluid velocity, and poor water quality make fouling worse. For example, biological fouling from algae or zebra mussels can occur if you do not maintain proper fluid velocity or use the right materials. Deposition fouling, like sediment buildup, often results from low flow rates or poor system design.

Common Causes | |

|---|---|

Biological (algae, mussels) | Low velocity, warm water, lack of cleaning |

Deposition (sediment, minerals) | Poor water quality, low flow, high temperature |

Corrosion fouling | Incompatible materials, poor grit removal |

Solutions for Fouling Prevention

You can prevent fouling in plate heat exchangers by following a few key steps:

Maintain high fluid velocity to reduce buildup.

Use corrosion-resistant materials such as stainless steel or titanium.

Schedule regular cleaning using methods like chemical, thermal, or ultrasonic cleaning.

Choose a plate heat exchanger with easy access for cleaning.

Shanghai Plate Heat Exchanger stands out as a trusted partner for fouling solutions. The HT-Bloc Welded Plate Heat Exchanger offers advanced cleaning features, including accessible channels for mechanical flushing, chemical cleaning, and ultrasonic cleaning. Ultrasonic cleaning can remove nearly all types of fouling, while thermal cleaning works well for organic deposits. These methods help restore full heat duty and keep your exchangers running efficiently.

Effectiveness Description | |

|---|---|

Hydroblasting | About 85% effective, labor-intensive |

Chemical Cleaning | 30-85% effective, depends on procedure |

Thermal Cleaning | Up to 100% effective for organic fouling |

Ultrasonic Cleaning | Near 100% effective for most fouling types |

Fouling costs industries billions each year due to extra energy use, lost production, and more frequent maintenance. By choosing the right plate heat exchanger and following best practices, you can avoid these costs and keep your operations reliable.

Corrosion—A Common Fault in Plate Heat Exchangers

Signs of Corrosion

You can spot corrosion in plate heat exchangers by looking for several clear warning signs. Corrosion often starts as small pits or craters on the metal surface. These pits form when the protective film on the plate breaks down, allowing aggressive ions to attack specific areas. You might also notice:

Discoloration or rust on the metal surfaces

Pitted, warped, or cracked or corroded plate

Leaks at joints or along the frame

Loose bolts or distorted frames

Cracks in plates or end plates

Corrosion can lead to leaks, reduced heat transfer efficiency, and even unexpected downtime. If you ignore these signs, you risk catastrophic failures that can halt your operations.

Why Corrosion Occurs

Corrosion happens when the metal in your plate heat exchanger reacts with its environment. This process is natural, but certain conditions make it worse. High temperatures, aggressive chemicals, and poor water quality speed up corrosion. Erosion from fast-moving fluids can strip away protective layers, exposing fresh metal to attack. Pitting corrosion creates deep, localized pits that can quickly cause leaks. Stress corrosion cracking appears when high stress and corrosive environments combine, leading to cracks that weaken the structure of your exchangers.

Corrosion does not just affect performance. It increases maintenance costs and shortens the service life of your equipment. Over time, you may face higher replacement costs and more frequent repairs.

Preventing Corrosion in PHEs

You can prevent corrosion by choosing the right materials and maintaining your plate heat exchangers properly. Material selection plays a key role in corrosion resistance. Stainless steel alloys offer excellent resistance and long-term durability. Titanium alloys provide exceptional corrosion resistance, especially in aggressive environments, though they come with higher initial costs. The table below compares common materials used in plate heat exchangers:

Material Type | Advantages | Disadvantages |

|---|---|---|

Stainless Steel | Excellent corrosion resistance, durable | Needs treatment, can bend or crack |

Copper-based Alloys | Good thermal conductivity, works in seawater | Moderate resistance in harsh settings |

Titanium Alloys | Exceptional resistance, long lifespan | Higher initial cost |

Composite Materials | Lightweight, enhanced thermal properties | Not widely available |

The HT-Bloc Welded Plate Heat Exchanger uses stainless steel and titanium to maximize corrosion resistance and durability. This design helps you avoid leaks and keeps your exchangers running longer, even in tough conditions. Regular inspection and cleaning also help prevent corrosion and erosion, protecting your investment and ensuring reliable performance from your phe plate heat exchanger.

Leakage in Welded Plate Heat Exchangers

Detecting Leaks

You need to spot leaks early in welded plate heat exchangers to prevent costly downtime and damage. Look for signs such as process fluid leakage around the unit, unexpected drops in system pressure, or an increased pressure drop across the exchanger. Sometimes, you may notice fluid pooling near the base or see visible corrosion at weld seams. If you detect a sudden loss of heat transfer efficiency, this can also signal a leak. Regular inspections help you catch these issues before they escalate.

Tip: Use a gas test with the plates installed to identify even small leaks that might not be visible during normal operation.

Causes of Leakage

Several factors can cause leaks in welded plate heat exchangers. You should pay attention to these common sources:

Welding quality: Poor welding can create microscopic cracks or holes at the weld joints. These flaws may expand over time and cause leaks.

Thermal stress: Large temperature changes during operation can make the metal expand and contract. This stress may exceed design limits and lead to failures.

Material selection: Using the wrong materials can result in corrosion or stress corrosion cracking, which eventually causes leaks.

Connection integrity: Weak tube-to-tube sheet connections may not seal properly, leading to leaks as the exchanger ages.

Corrosion and impurities: Corrosive fluids or impurities can erode the plate walls, creating paths for leaks.

Traditional plate heat exchangers often suffer from gasket failure, which is a major source of leaks. The HT-Bloc Welded Plate Heat Exchanger uses a fully welded, gasket-free design. This approach removes the risk of leaks caused by gasket wear and deterioration, making it ideal for high-pressure and high-temperature applications.

Fixing and Preventing Leaks

You can take several steps to repair and prevent leaks in your plate heat exchanger:

Check that your operating parameters match the original design specifications.

Clean the exchanger using chemical or mechanical methods to remove deposits that might damage the plate surfaces.

Install in-line filters to keep foreign particles out of the exchanger.

Follow proper startup and shutdown procedures to avoid sudden stress on the plates.

If you find a leak, consider welding repairs performed by qualified technicians to restore the integrity of the weld seams.

Routine maintenance and careful monitoring help you extend the life of your exchangers. By choosing robust designs like the HT-Bloc, you reduce the risk of process fluid leakage and minimize downtime. Reliable plate heat exchangers keep your operations safe and efficient.

Blockage and Flow Restrictions in Plate Heat Exchangers

Spotting Blockages

You can often spot blockages in plate heat exchangers by watching for a sudden loss of flow and performance. If you notice a higher pressure drop across the unit or your pumps seem to work harder, you may have a blockage. Sometimes, you will see uneven temperature readings at the inlet and outlet. These signs mean that fluid cannot move freely through the plate channels. When this happens, your system loses efficiency and energy costs rise.

Tip: Regularly monitor pressure gauges and temperature sensors. Early detection helps you avoid costly downtime and major repairs.

What Causes Flow Restrictions

Several factors can cause flow restrictions in plate heat exchangers. Impurities, fouling, and poor system design often lead to blocked channels. The table below shows some common causes and their effects:

Cause of Flow Restriction | Description |

|---|---|

Uneven flow through the plates reduces system performance. | |

Header-Induced Pressure Drop | Pressure drop from headers causes non-uniform flow. |

Phase Separation in Two-Phase Flow | Different flow patterns at the inlet can block some plate channels. |

End Channel and End Plate Effects | End plates with less heat transfer can change flow behavior and create restrictions. |

When blockages form, you see increased pressure drops. Pumps must work harder, which increases energy use. Over time, this puts stress on your exchangers and can lead to early breakdowns.

Clearing and Preventing Blockages

You can clear and prevent blockages by following a few best practices. Start with regular cleaning to remove deposits from each plate. The HT-Bloc Welded Plate Heat Exchanger features accessible channels, making cleaning easier and more effective. You can use mechanical flushing, chemical cleaning, or ultrasonic methods to keep the channels clear.

Shanghai Plate Heat Exchanger recommends these maintenance steps:

Water treatment and fluid quality control help prevent scaling and fouling.

Proper installation ensures fluid moves smoothly and avoids stagnation.

Maintain recommended flow rates and use compatible fluids for best results.

If you do find a blockage, act quickly to repair the issue. Remove the exchanger from service and clean the plates thoroughly. Check for any damage that might need further attention. By following these steps, you keep your phe plate heat exchanger running efficiently and avoid costly downtime.

Gasket and Seal Problems—Common Faults in Plate Heat Exchangers

Identifying Gasket Wear

You often see gasket and seal problems in a phe plate heat exchanger. Worn or damaged gaskets can lead to leaks, which affect product quality and system performance. Common symptoms include fluid escaping from the plate edges, visible cracks, and hardening of the gasket material. You may notice a failed gasket when the exchanger loses pressure or when you see fluid pooling near the unit. Regular inspections help you spot these issues before they cause major problems.

Tip: Check for discoloration or swelling in the gasket. These signs often point to chemical attack or excessive heat exposure.

Causes of Seal Failure

Several factors contribute to gasket failure in plate heat exchangers. Hydraulic hammering can displace gaskets, while rapid temperature changes affect the rubber’s resistance and flexibility. Gasket swelling and deformed grooves also lead to seal failure. Excessive clamping, especially overtightening, causes misalignment and damages the gasket, increasing the risk of leaks. Over time, gasket materials lose compressibility, which reduces sealing effectiveness. Aging and chemical erosion further weaken the gasket, making it less reliable.

Most frequently observed causes of seal failure:

Hydraulic hammering and abnormal pressure impacts

Gasket swelling due to incompatible fluids

Deformed gasket grooves from poor installation

Loss of compressibility from aging or heat

Maintenance and Replacement Tips

You can maintain high exchanger quality by following industry standards for gasket care. Inspect gaskets every six months, even if the unit seems to perform well. Look for cracks, hardening, or other damage. Most gaskets last one to two years, depending on operating conditions. Replace any damaged or worn gaskets promptly to prevent leaks and maintain product quality.

Recommended maintenance steps:

Schedule regular inspections for all seals and gaskets

Replace failed gasket immediately to avoid system downtime

Use compatible gasket materials for better erosion resistance

Avoid overtightening during installation to prevent misalignment

The HT-Bloc Welded Plate Heat Exchanger uses a gasket-free design. This feature eliminates gasket and seal problems, making it ideal for critical applications where leaks and maintenance interruptions are unacceptable. You benefit from improved reliability and resistance to erosion, ensuring your exchangers deliver consistent performance.

You improve long-term reliability when you address common faults in your phe plate heat exchanger. Shanghai Plate Heat Exchanger and the HT-Bloc Welded Plate Heat Exchanger offer advanced solutions that help you avoid costly downtime. Regular inspections and proactive maintenance keep your system running at peak performance.

Regular maintenance routines help you spot issues early.

Cleaning procedures prevent fouling and scaling.

Proactive monitoring reduces unplanned outages.

Inspections for damage and cleanliness support reliability.

Documenting maintenance activities helps track trends.

Expert consultations ensure compliance and safety.

FAQ

What is the main advantage of a welded plate heat exchanger like the HT-Bloc?

You get a gasket-free, fully welded design. This means you avoid leaks, handle higher pressures, and reduce maintenance. The HT-Bloc works well in demanding environments.

How often should you clean your plate heat exchanger?

You should inspect and clean your exchanger every six months. If you notice a drop in performance or see fouling, clean it sooner. Regular cleaning keeps your system efficient.

Can you use the HT-Bloc Welded Plate Heat Exchanger with aggressive fluids?

Yes. The HT-Bloc uses stainless steel or titanium plates. These materials resist corrosion from aggressive fluids. You can use it in harsh chemical or industrial settings.

What signs show your plate heat exchanger needs maintenance?

Watch for leaks, pressure drops, or uneven temperatures. If you see fluid around the unit or hear unusual noises, schedule maintenance. Early action prevents bigger problems.