Fully Welded Heat Exchangers vs Gasketed Plate Heat Exchangers Which Is Right for Your Industry

Plate Heat Exchanger Types Compared

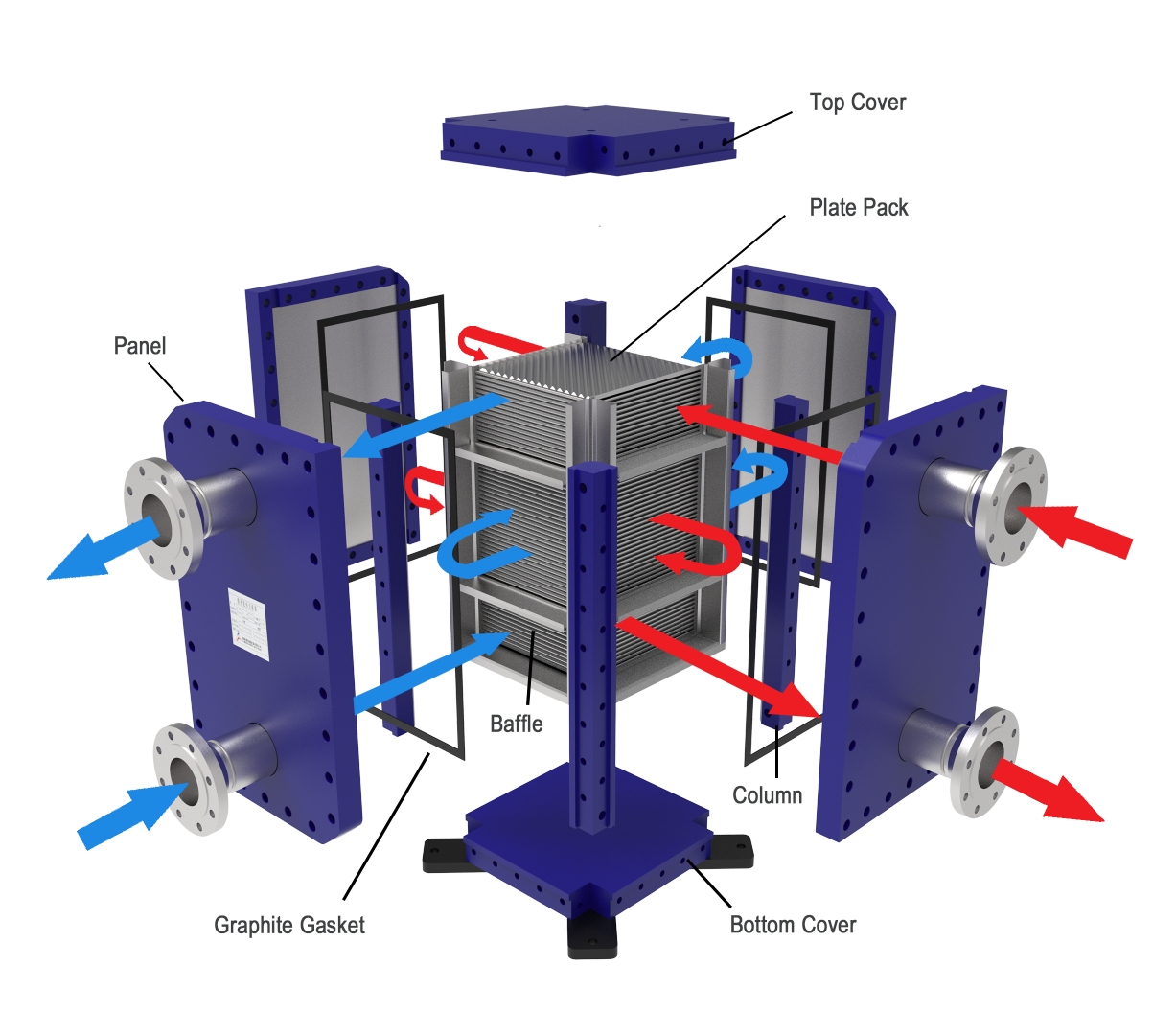

Fully Welded Heat Exchanger Overview

A fully welded plate heat exchanger uses metal plates joined by welding instead of gaskets. This design creates a permanent seal that prevents leaks, even under extreme pressure or temperature. Many industries choose this type for handling aggressive or hazardous fluids. The HT-Bloc Welded Plate Heat Exchanger from Shanghai Plate Heat Exchanger stands out in this category. It offers high efficiency and reliability, especially in demanding environments. The welded construction reduces fouling and supports easy cleaning. High turbulence inside the unit boosts heat transfer, making it a top choice for critical applications.

Gasketed Plate Heat Exchangers Overview

Gasketed plate heat exchangers use gaskets between plates to create a seal. These gaskets allow for easy disassembly and maintenance. Many facilities prefer this type for processes that require frequent cleaning or inspection. Gasketed plate heat exchangers work well in moderate temperature and pressure conditions. They offer flexibility because users can add or remove plates to adjust capacity. However, the gaskets can wear out over time, which may lead to leaks if not replaced regularly.

When comparing fully welded and gasketed plate heat exchangers, users should consider maintenance needs, operating conditions, and long-term reliability.

Gasketed Plate Heat Exchanger | Welded Plate Heat Exchanger | |

|---|---|---|

Maintenance | Easier to maintain; gaskets can be replaced easily | More permanent; cannot be easily disassembled |

Operating Conditions | Flexible; suitable for varying conditions | Best for high temperatures, pressures, and corrosive fluids |

Cost | Generally lower initial cost | Typically higher initial cost due to precision welding |

Risk of Leaks | Potential leaks due to gasket degradation | No risk of gasket failure; permanent seal |

Compactness | Less compact due to gasket grooves | More compact; lower risk of fouling |

Shanghai Plate Heat Exchanger recommends the HT-Bloc Welded Plate Heat Exchanger for industries that demand maximum reliability and efficiency. This advanced plate heat exchanger delivers outstanding performance where gasketed plate heat exchangers may not suffice.

Fully Welded Heat Exchanger Features

Design and Construction

A fully welded heat exchanger stands out due to its robust construction. Engineers join metal plates using advanced welding techniques, which eliminates the need for gaskets. This design creates a permanent seal and minimizes the risk of leakage. The HT-Bloc Welded Plate Heat Exchanger from Shanghai Plate Heat Exchanger uses high-quality materials such as stainless steel and titanium. Its modular design allows for easy customization and scalability. The following table highlights key design features that distinguish a fully welded heat exchanger from other types:

Feature | Welded Plate Heat Exchangers | Other Plate Heat Exchangers |

|---|---|---|

Risk of Leakage | Minimized | Higher due to gaskets |

Temperature Handling | Higher | Limited by gaskets |

Pressure Handling | Higher | Limited by gaskets |

Corrosive Fluid Handling | Better | Limited by gaskets |

Durability | More durable | Less durable |

Cleanability | Not manually cleanable | Can be manually cleaned |

Key Advantages

A fully welded heat exchanger offers several advantages for industrial applications. The welded construction eliminates non-metallic sealing materials, which allows the unit to operate at higher temperatures and pressures. The HT-Bloc Welded Plate Heat Exchanger can handle maximum working pressures up to 3.0 MPa and temperatures up to 300°C. Its compact footprint saves valuable space in facilities. Users benefit from high efficiency and reliable performance, especially when handling aggressive or hazardous fluids. Maintenance is simple due to accessible heat transfer channels and openable bolted connections. Shanghai Plate Heat Exchanger provides solutions that meet the needs of power generation, offshore engineering, and metallurgy.

Limitations

While a fully welded heat exchanger delivers outstanding durability and leak resistance, some limitations exist in industrial settings. Welded tubes may develop cracks in corrosive or critical applications. Operators often choose alternatives to reduce downtime caused by weld cracks. The risk associated with welded tubes may outweigh cost savings if a rupture occurs. Careful selection and regular inspection help maintain long-term reliability.

Gasketed Plate Heat Exchangers Features

Design and Construction

Gasketed plate heat exchangers use a series of thin plates stacked together. Each plate creates a channel for fluid flow, and a gasket sits between the plates to seal the unit and direct fluids. The modular design allows engineers to add or remove plates to adjust capacity. Facilities often select gasketed units for processes that require frequent cleaning or inspection. The gasketed construction makes it easy to access individual plates for maintenance. Operators can replace a gasket without disassembling the entire exchanger.

Advantages

Gasketed plate heat exchangers offer several benefits for industrial applications:

Capacity expands by adding plates, making the system cost-effective and efficient when demand changes.

Quick maintenance and gasket replacements minimize disruptions.

Adaptability to changing process requirements due to easy expansion and modification.

Modular design allows customization for specific application needs.

Maintenance is simplified because individual plates can be removed and replaced, reducing downtime during servicing.

Facilities can clean plates without special tools, supporting regular upkeep.

Tip: Gasketed plate heat exchangers provide flexibility for industries with variable production needs.

Limitations

Gasketed plate heat exchangers face some challenges in demanding environments. The following table summarizes common concerns:

Limitation | Description |

|---|---|

Limited temperature and pressure tolerance | Gasketed plate heat exchangers have lower tolerance compared to shell-and-tube types. |

Gasket wear | Leads to leakage, increased maintenance, and higher costs. |

Fouling and scaling buildup | Common with dirty fluids, reducing overall efficiency. |

Frequent temperature fluctuations can lead to material fatigue. | |

Mechanical fatigue | Pressure cycles can cause gasket failure and potential leaks. |

Facilities should evaluate process conditions before selecting gasketed plate heat exchangers. For high-pressure or high-temperature applications, Shanghai Plate Heat Exchanger’s HT-Bloc Welded Plate Heat Exchanger may offer a more robust solution.

Maintenance and Reliability

Cleaning and Servicing

Regular cleaning keeps plate heat exchangers running at peak efficiency. Operators should clean equipment before fouling becomes severe or when process issues threaten production. Gasketed plate heat exchangers allow easy access for manual cleaning. Technicians can open the plate pack, apply cleaning agents, and rinse with a soft brush or high-pressure water. Clean-In-Place (CIP) methods let users flush water and cleaning agents through the system without disassembly. Chemical cleaning works well for stubborn deposits. High-pressure water jet cleaning removes tough fouling and restores efficiency.

Fully welded plate heat exchangers, such as the HT-Bloc from Shanghai Plate Heat Exchanger, require less frequent maintenance. Cleaning procedures may be more complex, often involving disassembly for thorough servicing. However, these units maintain optimal efficiency over longer periods, minimizing downtime and labor costs. Effective cleaning methods help restore equipment to optimal condition, maintain performance, reduce pump energy consumption, and prevent harmful bacteria formation.

Tip: Choosing the right cleaning method improves efficiency and ensures product quality.

Leak Resistance and Durability

Leak resistance and durability play a vital role in heat exchanger reliability. Fully welded designs, like the HT-Bloc, use permanent metallurgical bonds that provide high leak resistance and durability. These units handle high stress and heat, maintaining efficiency in demanding environments. Gasketed plate heat exchangers offer moderate leak resistance and durability. They require more frequent maintenance to prevent leaks, especially as gaskets age.

Feature | Fully Welded (Brazed) | Gasketed |

|---|---|---|

Leak Resistance | High | Moderate |

Maintenance | Low | High |

Durability | High | Moderate |

Disassembly for Cleaning | No | Yes |

Corrosion Resistance | Moderate | Variable |

Brazed units deliver reliable performance and efficiency for high-pressure and high-temperature applications. Gasketed types suit moderate conditions and allow easier cleaning. Shanghai Plate Heat Exchanger’s HT-Bloc Welded Plate Heat Exchanger stands out for industries seeking maximum efficiency and long-term reliability.

Operating Conditions and Applications

Temperature and Pressure Suitability

Selecting the right plate heat exchanger depends on the operating environment. Fully welded plate heat exchangers, such as the HT-Bloc from Shanghai Plate Heat Exchanger, perform well in extreme conditions. These units handle high temperatures and pressures, making them ideal for challenging heat transfer tasks. Gasketed plate heat exchangers work best in moderate environments where frequent maintenance is necessary. The following table compares the recommended operating ranges:

Type of Heat Exchanger | Maximum Pressure | |

|---|---|---|

All-welded Plate Heat Exchanger | 300°C | 3.0 MPa |

Detachable Plate Heat Exchanger | < 150°C | < 1.6 MPa |

Engineers choose fully welded designs for processes that demand reliable heat transfer under harsh conditions. Gasketed models suit applications with lower temperature and pressure requirements.

Industry Use Cases

Different industries require specific heat transfer solutions. Power generation plants rely on fully welded plate heat exchangers for efficient heat transfer in steam and cooling systems. Chemical processing facilities use these units to manage aggressive fluids and maintain stable heat transfer even when exposed to corrosive substances. Offshore engineering projects benefit from the robust construction of welded designs, ensuring consistent heat transfer in demanding marine environments. Food and beverage manufacturers often select gasketed plate heat exchangers for easy cleaning and flexible heat transfer capacity. Metallurgy operations depend on the HT-Bloc for reliable heat transfer during metal processing. Shanghai Plate Heat Exchanger provides advanced solutions that optimize heat transfer and support energy efficiency across all these sectors.

Cost and Value

Initial Investment

When evaluating plate heat exchangers, companies often focus on the initial investment. Fully welded and gasketed plate heat exchangers both require a higher upfront cost compared to traditional heat exchangers. This higher capital requirement can present a challenge for small and medium-sized businesses. However, the investment brings significant benefits over time. Decision-makers should weigh the initial expense against the potential for long-term operational savings and improved energy efficiency.

Fully welded and gasketed plate heat exchangers typically cost more at the outset than conventional designs.

The higher price reflects advanced engineering, durable materials, and enhanced performance.

Long-term value often outweighs the initial cost, especially in demanding industrial environments.

Shanghai Plate Heat Exchanger (SHPHE) offers the HT-Bloc Welded Plate Heat Exchanger, which delivers robust performance and reliability. This product stands out as a smart investment for industries seeking efficiency and durability.

Operating and Maintenance Costs

Operating and maintenance costs play a crucial role in the total cost of ownership. Fully welded plate heat exchangers, such as the HT-Bloc, require less frequent maintenance due to their gasket-free design. This feature reduces the risk of leaks and minimizes downtime. Facilities benefit from lower labor costs and fewer interruptions to production. Gasketed plate heat exchangers may need more regular servicing, especially as gaskets age and require replacement.

Note: Choosing a heat exchanger with lower maintenance needs can lead to significant savings over the equipment’s lifespan.

SHPHE’s HT-Bloc model helps industries achieve long-term cost efficiency by combining high performance with minimal maintenance requirements.

Industry Recommendations

Chemical and Petrochemical

Chemical and petrochemical industries demand heat exchanger solutions that withstand aggressive fluids, high pressures, and extreme temperatures. Engineers must consider fluid properties, corrosion resistance, temperature adaptability, sealing performance, and economic feasibility. The following table summarizes the most important factors for selecting a heat exchanger in these environments:

Factor | Description |

|---|---|

Fluid Properties | Understanding the properties of the fluids being processed is essential for material selection. |

Corrosion Resistance | Materials must resist corrosion to ensure longevity and efficiency. |

Temperature Adaptability | The ability of materials to withstand varying temperatures is critical for operational stability. |

Sealing Performance | Effective sealing materials are necessary to prevent leaks and maintain efficiency. |

Economic Feasibility | Cost considerations are important to ensure the project remains within budget while meeting requirements. |

Shanghai Plate Heat Exchanger’s HT-Bloc Welded Plate Heat Exchanger excels in these demanding conditions. The fully welded design provides superior corrosion resistance and high heat transfer efficiency. Operators benefit from low pressure drop and reliable sealing, which minimizes maintenance and downtime. The HT-Bloc model supports compliance with technological process conditions and offers a higher heat transfer coefficient. Its accessible channels allow for effective cleaning, and the modular design ensures economical use of materials. These features make the HT-Bloc an ideal choice for chemical and petrochemical facilities seeking robust thermal performance.

Food and Beverage

Food and beverage processing requires heat exchanger solutions that prioritize hygiene, durability, and efficient heat transfer. Stainless steel construction maintains a hygienic surface, which is crucial for food safety. The table below outlines the unique requirements for plate heat exchangers in this sector:

Requirement | Description |

|---|---|

Hygiene | Stainless steel maintains a hygienic surface, crucial for food safety. |

Durability | It withstands high pressure and temperature variations, ensuring longevity. |

Corrosion Resistance | Offers resistance to corrosion, essential for maintaining product quality. |

Heat Transfer Efficiency | Provides an efficient surface for heat transfer, vital for temperature-sensitive processes. |

Plate heat exchangers play a key role in pasteurizing beverages, controlling bacterial levels, and enhancing flavor. Gasketed plate heat exchangers are common in the food industry due to their easy cleanability and flexibility. However, fully welded designs like the HT-Bloc Welded Plate Heat Exchanger offer greater durability and fewer temperature and pressure constraints. The HT-Bloc model resists fouling and corrosion, making it suitable for a wide range of food and beverage applications. Operators can rely on its long-term serviceability and efficient cleaning options, ensuring consistent product quality and safety.

Power Generation and HVAC

Power generation and HVAC systems require heat exchanger solutions that deliver high thermal efficiency, reliability, and adaptability. Engineers must define process requirements, including temperature, pressure, flow rate, and heat load. The table below highlights key considerations for selecting a heat exchanger in these industries:

Consideration | Description |

|---|---|

Process Requirements | Define temperature, pressure, flow rate, and heat load for the application. |

Type of Fluids Involved | Assess compatibility and fouling potential based on fluid characteristics. |

Thermal Efficiency | Evaluate heat transfer efficiency, surface area, and material conductivity. |

Space Constraints and Installation | Consider the physical space available and the flexibility of installation options. |

Maintenance and Cleaning Requirements | Determine ease of access for cleaning and frequency of maintenance needed. |

Compliance with Industry Standards | Ensure adherence to relevant safety and quality regulations. |

Shanghai Plate Heat Exchanger’s HT-Bloc Welded Plate Heat Exchanger meets the rigorous demands of power generation and HVAC applications. The compact design saves valuable space, while high heat transfer efficiency optimizes energy use. The HT-Bloc model supports central air-conditioning systems, heat exchange stations, and heat pump systems. Its robust construction ensures reliable operation in high-pressure and high-temperature environments. Maintenance is straightforward, and the modular design allows for easy expansion to meet changing needs.

Why Choose Shanghai Plate Heat Exchanger

Shanghai Plate Heat Exchanger stands out as a trusted provider of advanced heat exchanger solutions for diverse industries. The HT-Bloc Welded Plate Heat Exchanger offers high heat transfer efficiency, compact design, and low fouling. Operators benefit from ease of maintenance and adaptability to various applications, including chemical processing, food and beverage, power generation, HVAC, marine, and pharmaceuticals.

The plate heat exchanger from SHPHE simplifies maintenance with easy detection of blockage and corrosion. Cleaning processes are straightforward, and repair options are simple. Users can expand heat exchange capacity by adding more plates, provided the frame and interface are compatible.

Facilities seeking reliable, efficient, and durable heat exchanger solutions should consider Shanghai Plate Heat Exchanger and the HT-Bloc Welded Plate Heat Exchanger. These products deliver outstanding thermal performance and long-term value for demanding industrial environments.

Selecting the right plate heat exchanger depends on heat transfer needs, fluid compatibility, and maintenance. The table below highlights key decision factors:

Decision Factor | Description |

|---|---|

Heat Transfer Requirements | Required rate, temperature, pressure drop |

Fluid Compatibility | Material and gasket suitability |

Maintenance | Ease of servicing and spare part availability |

Shanghai Plate Heat Exchanger’s HT-Bloc offers durability and efficiency. For expert advice, readers can contact SHPHE for tailored solutions.

FAQ

What makes fully welded plate heat exchangers suitable for harsh environments?

Fully welded plate heat exchangers resist high pressure and temperature. SHPHE’s HT-Bloc model offers reliable performance in demanding industrial settings.

How often should operators clean a plate heat exchanger?

Operators should clean plate heat exchangers regularly to maintain efficiency. SHPHE recommends scheduled maintenance for the HT-Bloc to reduce downtime.

Can facilities customize the HT-Bloc Welded Plate Heat Exchanger?

Facilities can customize the HT-Bloc Welded Plate Heat Exchanger. SHPHE provides modular designs that adapt to specific thermal requirements.