Leakage free air preheater picks that stop waste now

Looking for the best leakage free air preheater? Here are the top picks: Shanghai Heat Transfer’s Plate Air Preheater, BDHeatRecovery’s welded plate exchangers, Ljungström’s ultra-low leakage tech, and SDWintech’s certified stainless steel models. These brands keep energy waste in check and deliver reliable performance every time.

Why leakage-free air preheater matters

Energy efficiency benefits

A leakage free air preheater plays a big role in saving energy for many industries. When air preheaters have leaks, hot exhaust gases mix with incoming air. This lowers the temperature of the air that enters boilers or furnaces. As a result, the system uses more fuel to reach the right temperature. With a leakage free air preheater, companies can stop this waste and keep their systems running at peak efficiency.

Shanghai Heat Transfer’s Plate Air Preheater stands out because it uses a smart design with corrugated metal plates. This design keeps hot and cold air separate, so heat transfer works better. Many factories see less frost buildup and better heat recovery when they use this kind of technology. They also avoid common problems like reduced efficiency and wasted energy.

Tip: Choosing a leakage free air preheater helps companies avoid extra maintenance and keeps operations smooth.

Reducing fuel and emissions

Switching to a leakage free air preheater does more than just save energy. It also helps the environment. When leaks are gone, the system burns less fuel. Some companies have cut fuel use by over 65%. They also see a drop in CO2 emissions—sometimes as much as 79%. This makes a big difference for businesses that want to meet strict environmental rules.

A leakage free air preheater also reduces safety risks. Leaks can cause dangerous mixing of air and flue gas, which may lead to fire hazards. By using advanced models like the Plate Air Preheater, companies can keep their workers safe and protect the planet at the same time.

Leading leakage free air preheater brands

Shanghai Heat Transfer – Plate Air Preheater

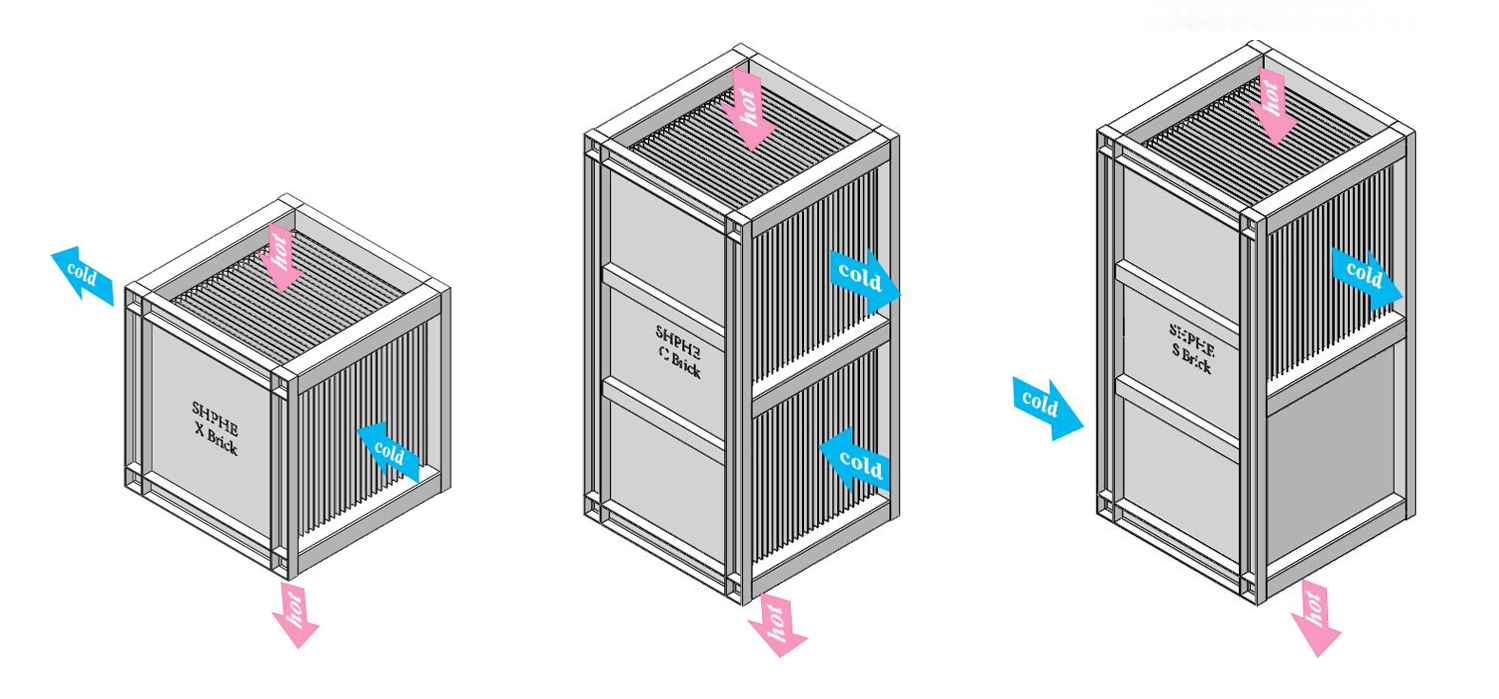

Shanghai Heat Transfer’s Plate Air Preheater stands out as a top choice for companies that want a reliable leakage free air preheater. The modular design makes installation and maintenance easy. Each plate module can be replaced or reconfigured without stopping the whole system. This feature saves time and keeps operations running smoothly.

The Plate Air Preheater uses corrosion-resistant materials, so it lasts longer even in tough industrial settings. Its compact structure fits into tight spaces, and the corrugated plates boost heat transfer efficiency. Many industries, like oil and gas or chemical plants, choose this model to recover waste heat and cut down on fuel use. By using this technology, companies see lower emissions and better energy savings. Shanghai Heat Transfer’s solution is a smart investment for anyone who wants to stop energy waste and improve sustainability.

Note: Shanghai Heat Transfer’s Plate Air Preheater is highly recommended for those seeking a proven leakage free air preheater with flexible design and strong performance.

BDHeatRecovery – Welded plate exchangers

BDHeatRecovery offers welded plate exchangers that focus on durability and leak prevention. Their products use robust welding techniques to seal every plate, which helps keep hot and cold streams separate. Many users report fewer leaks and less downtime. BDHeatRecovery’s exchangers work well in high-pressure environments and are popular in heavy industry.

Ljungström – Ultra-low leakage tech

Ljungström leads the way with ultra-low leakage technology. Their air preheaters use advanced seal designs, including full-contact radial seals and self-reinforcing circumferential seals. These seals reduce leakage by up to 50% compared to older models. The DuraMax radial seal keeps continuous contact with the sealing plate, blocking leakage paths. DuraFlex circumferential seals close gaps and openings, which makes Ljungström’s air preheaters much more effective than traditional designs. Many companies trust Ljungström for reliable performance and lower energy loss.

SDWintech – Certified stainless steel models

SDWintech’s stainless steel air preheaters come with strong certifications that prove their leakage-free performance. These models meet strict quality, safety, and environmental standards.

Many industries choose SDWintech for their reliable stainless steel construction and proven track record in leak prevention.

Other notable brands

Several other brands also offer trusted leakage free air preheater solutions. Here are some recognized market leaders based on sales:

Miller Electric (estimated sales: $300 million)

EFD Induction (estimated sales: $200 million)

Inductotherm Group (estimated sales: over $500 million)

Other notable names include SterlingTT, Howden, Rizzi Engineering, Super Radiator Coils, Sigma Thermal, TUTCO SureHeat, John Zink, and Kelvion. These companies provide a range of air preheater models designed to minimize leaks and maximize efficiency.

The market for leakage free air preheater technology is growing steadily. More companies want energy-efficient solutions and care about sustainability. In places like Italy, demand for flue gas air preheaters is rising fast, thanks to new regulations and better technology.

Tip: Choosing a brand with proven leak prevention and strong certifications helps companies save energy and meet environmental goals.

Top leakage free air preheater products

Plate Air Preheater by Shanghai Heat Transfer

Shanghai Heat Transfer’s Plate Air Preheater stands out in the market for its smart engineering and reliable performance. Many industries choose this model because it helps them recover more heat, save fuel, and cut emissions. The modular design makes it easy to install and maintain. If a plate needs replacing, workers can swap it out without shutting down the whole system. This keeps downtime low and productivity high.

The Plate Air Preheater uses stainless steel and advanced air film technology. This means it resists corrosion and lasts longer, even in harsh environments. Its compact structure fits into tight spaces, making it a favorite for plants with limited room. The unit also prevents acid dew point corrosion, which protects equipment and saves on repair costs.

Here’s a quick look at the technical specs:

Specification | Details |

|---|---|

Model NO. | HT-AD |

Certification | CE, ISO, ASME U Stamp |

Application | Heater, Cooler, Vaporizer, Condenser |

Principle | Regenerative Heat Exchanger |

Style | Plate Type |

Material | Stainless Steel |

Technology | Air Film |

Trademark | SHPHE |

Transport Package | Wood |

Specification | 150 |

Origin | China |

HS Code | 84195000 |

Key features include:

Modular design for easy maintenance

High heat transfer performance with low pressure drop

Strong anti-corrosion capability and durability

Acid dew point corrosion prevention

Safe and reliable operation

Compact structure and small footprint

High efficiency and strong heat recovery

Note: Many companies see lower energy bills and fewer emissions after switching to this leakage free air preheater.

BDHeatRecovery robust plate units

BDHeatRecovery offers plate units built for tough jobs. Their welded plate exchangers use strong seals to keep hot and cold air separate. This design helps prevent leaks, even when the system runs under high pressure. Many factories trust these units because they last a long time and need little maintenance.

The welded plates also help the unit handle temperature swings without cracking or leaking. BDHeatRecovery’s products work well in heavy industries like steel, cement, and power generation. Users often report fewer shutdowns and lower repair costs. These plate units help companies keep their systems running smoothly and efficiently.

Ljungström advanced models

Ljungström’s advanced air preheaters use a unique rotating rotor packed with heat transfer plates. This design boosts efficiency and helps power plants save energy. The rotor spins, moving heat from exhaust gases to incoming air. Ljungström models reach an effectiveness of about 85%, which means they recover most of the waste heat.

Engineers use computer simulations to test and improve these preheaters. They check how well the unit transfers heat and how evenly it spreads temperature. This careful testing leads to better performance and fewer problems in real-world use. Many power plants pick Ljungström because the models help them meet strict energy and emission targets.

Tip: Ljungström’s technology works best in large plants that need reliable, high-efficiency heat recovery.

SDWintech certified air preheaters

SDWintech’s certified air preheaters focus on leak prevention and durability. These models use high-quality stainless steel and pass strict tests for safety and performance. Third-party tests show that leaks through seals can cause big energy losses and make fans work harder. Radial seal leakage sometimes goes over 40%, but SDWintech’s designs keep leakage much lower.

By reducing leaks, these air preheaters help companies save energy and cut costs. The strong construction also means fewer breakdowns and less time spent on repairs. Many industries choose SDWintech for their proven track record and reliable results.

Note: Companies that want to avoid thermal losses and extra fan power often turn to SDWintech’s certified models.

Product comparison table

Product | Leakage Prevention | Efficiency & Durability | User Feedback |

|---|---|---|---|

Plate Air Preheater (Shanghai Heat Transfer) | Triple-seal, modular design | High efficiency, corrosion-resistant | ⭐⭐⭐⭐⭐ Reliable, easy to maintain |

BDHeatRecovery Welded Plate Exchanger | Welded, robust seals | Durable, handles high pressure | ⭐⭐⭐⭐ Long-lasting, low downtime |

Ljungström Ultra-low Leakage Model | Advanced multi-seal system | High effectiveness, tested in power plants | ⭐⭐⭐⭐ Trusted for large plants |

SDWintech Certified Stainless Steel | Certified, tight seals | Strong, stainless steel build | ⭐⭐⭐⭐ Proven leak prevention |

Leakage prevention

Many air preheaters use advanced seal systems to stop leaks. Triple-seal designs, like those in Shanghai Heat Transfer’s Plate Air Preheater, keep hot and cold air separate even when pressure changes. Multiple seals work better than single seals, especially when the gap is small. Welded plate exchangers from BDHeatRecovery also show strong leak prevention. Ljungström uses full-contact and circumferential seals to block air paths. SDWintech relies on certified tight seals for reliable performance.

Traditional rotary systems often have higher leakage.

Double and triple seals reduce leaks, with triple seals working best in tight spaces.

Welded designs offer extra protection in tough jobs.

Efficiency and durability

Shanghai Heat Transfer’s Plate Air Preheater stands out for its high efficiency and corrosion resistance. The modular design makes it easy to replace parts, which helps the unit last longer. BDHeatRecovery’s welded units handle high pressure and temperature swings. Ljungström’s models reach up to 85% effectiveness in heat recovery. SDWintech’s stainless steel build means fewer breakdowns and strong durability.

Note: Choosing a model with high efficiency and strong materials saves money and cuts downtime.

User feedback

Users give top marks to Shanghai Heat Transfer’s Plate Air Preheater for its reliability and simple maintenance. Many say it lowers energy bills and keeps systems running. BDHeatRecovery and Ljungström also get positive reviews for durability and performance. SDWintech earns praise for leak prevention and solid construction.

Shanghai Heat Transfer: “Easy to maintain and very reliable.”

BDHeatRecovery: “Lasts for years with little trouble.”

Ljungström: “Great for big plants needing steady heat recovery.”

SDWintech: “No leaks and strong build.”

Choosing the right leakage free air preheater

Assessing system needs

Selecting the best leakage free air preheater starts with understanding the system’s requirements. Engineers look at several factors before making a decision:

Air ingress can lower energy efficiency and increase auxiliary power use.

Regular maintenance helps keep leakage rates low and performance high.

Ambient air temperature affects how well the preheater transfers heat and can change leakage rates.

The design and arrangement of tubes play a big role in thermal efficiency and leakage control.

Shanghai Heat Transfer’s Plate Air Preheater offers a modular design that adapts to different system layouts. Many industries choose this model because it fits tight spaces and handles varying temperatures with ease.

Tip: Always match the air preheater’s capacity and design to the plant’s operating conditions for the best results.

Installation and maintenance

Proper installation and regular maintenance keep air preheaters working efficiently. Teams should reserve enough space for cleaning and inspections. Daily checks on inlet and outlet temperatures (usually between 150-300°C) help spot issues early. Monthly tasks include testing soot-blowing systems and measuring leakage rates. Annual overhauls involve checking corrosion and recalibrating seals.

Routine visual inspections catch leaks, corrosion, or damage before they become serious. Cleaning steam coils and tubes prevents fouling. Managing condensate drainage and maintaining steam quality also protect the equipment.

Note: Shanghai Heat Transfer’s modular design makes maintenance simple. Workers can replace individual plate modules without stopping the whole system.

Budget considerations

Budget plays a key role in choosing an air preheater. Companies look for models that offer strong performance and low maintenance costs. Durable materials, like those in Shanghai Heat Transfer’s Plate Air Preheater, reduce repair expenses over time. Investing in a reliable, leakage free air preheater saves money on fuel and energy bills.

Modular units often cost less to maintain.

High-quality seals and corrosion-resistant materials extend lifespan.

Efficient models lower energy consumption, which cuts operational costs.

Choosing a proven model like Shanghai Heat Transfer’s Plate Air Preheater helps companies control costs and boost efficiency.

Real-world results

SHPHE case study

Shanghai Heat Transfer’s Plate Air Preheater has made a big impact in real industrial settings. One chemical plant in Southeast Asia installed the Plate Air Preheater to recover waste heat from flue gas. The team noticed a drop in fuel consumption within weeks. Plant managers reported a 20% reduction in energy bills. Emissions also fell, helping the company meet strict local regulations.

The modular design allowed the maintenance crew to swap out a plate module during routine checks. They did not need to stop the whole system. This flexibility kept production on schedule and avoided costly downtime. The corrosion-resistant materials held up well, even with harsh exhaust gases. The plant’s engineers now recommend the Plate Air Preheater for other sites in their network.

Tip: Companies that want fast results and easy maintenance often choose Shanghai Heat Transfer’s Plate Air Preheater.

Industry testimonials

Many industry professionals share stories about the importance of leak prevention in air preheaters. They know that small leaks can grow into bigger problems if ignored.

Evaporators do not fail suddenly. They fail quietly, over time. Leaks start small: At tube joints, At return bends, At distributor connections, At vibration points. Ignoring these early signs does not save money. It only delays failure — and increases the damage.

Users say that switching to leakage-free models, like those from Shanghai Heat Transfer, helps them avoid these hidden risks. They see fewer breakdowns and more stable performance year after year. Reliable air preheaters keep operations smooth and protect equipment investments.

Leakage-free air preheaters, like the Plate Air Preheater from Shanghai Heat Transfer, help companies save energy and cut costs. Recent inspections found leaks in over a third of air preheater tubes, showing why upgrades matter.

Leaks grew from 267 to 37% of tubes in just six months.

Now is the time to act.

FAQ

What makes a leakage free air preheater important?

A leakage free air preheater saves energy and lowers emissions. It keeps hot and cold air separate, which helps companies cut fuel costs and meet environmental goals.

How often should companies maintain their air preheater?

Most experts suggest checking the air preheater monthly. Regular maintenance keeps the system efficient and helps spot leaks early.

Which air preheater is best for easy maintenance?

Many users recommend the Plate Air Preheater from Shanghai Heat Transfer. Its modular design lets workers replace parts quickly without stopping the whole system.