How 700 Bar Hydrogen Precoolers Are Shaping Refueling Infrastructure

Imagine you drive to a hydrogen refueling station. You get a fast and safe refueling because of hydrogen precooler 700 bar technology. New reports say better cooling systems stop things from getting too hot. They also make refueling stations work better. You get help from good temperature control and digital checks. These things make refueling safer and more efficient. Companies like SHPHE use Printed Circuit Heat Exchanger technology. This lets them refuel at high pressure. It helps the future of hydrogen cars and trucks.

Hydrogen Precooler 700 Bar: The Basics

What Is a Hydrogen Precooler?

When you fill up your hydrogen car, the gas is squeezed very hard. This squeezing makes the gas hot. A hydrogen precooler 700 bar cools the gas before it goes into your car. The gas can get as cold as -40°C. This keeps your car’s tank from getting too hot. It also helps make refueling safer and quicker.

The cooler gas helps stop things from overheating.

You can fill up faster because the system does not need to wait for cooling.

Lowering the gas temperature helps the station follow safety rules.

Some stations use special chillers to keep the hydrogen cold enough. These chillers use heat exchangers, like the ones from SHPHE, to make sure the cooling works well. This technology helps more stations open by making them work better.

Why 700 Bar Matters

Many new hydrogen stations use 700 bar pressure. This high pressure lets you put more hydrogen in your car’s tank. You can drive longer before you need to refuel. Smaller cars need this high pressure because they have less room for tanks. The station pushes hydrogen from low pressure up to 700 bar so you get a full tank.

Higher pressure means you can drive farther.

You do not need as much space in your car for hydrogen.

Using 700 bar helps clean energy and hydrogen production grow.

When you use a station with 700 bar, you get the newest refueling technology. This makes hydrogen cars easier to use every day.

Technical Challenges in Hydrogen Refuelling Stations

Heat Generation at High Pressure

When you go to hydrogen refuelling stations, you see how fast it works. This speed happens because the station uses very high pressure, like 700 bar. When hydrogen gas gets squeezed, it makes a lot of heat. If the heat is not controlled, the temperature goes up quickly. This can make refuelling unsafe and slow. Cooling systems are needed to keep things at the right temperature. SHPHE uses special technology for this job. Their Printed Circuit Heat Exchanger cools the hydrogen before it goes into your car. This keeps refuelling safe and easy.

Here are some main problems:

You need strong compression technology for high pressure.

The station has high running costs.

Cooling systems must handle heat from squeezing the gas.

Different starting pressures make refuelling harder.

Risks Without Precooling

If you skip precooling, there are many risks. The hydrogen gas can get too hot while refuelling. This heat can hurt your car’s tank or the station’s machines. You might have to wait longer for things to cool down before you finish refuelling. This makes the whole process slower at hydrogen stations. Without good cooling, the station cannot work fast enough. You may see longer lines and less steady service.

Precooling helps stations follow safety rules. It keeps you and the equipment safe. As more people use hydrogen cars, safe and quick refuelling is needed. Good cooling helps hydrogen production and makes the system work better.

Tip: Pick stations with advanced cooling, like SHPHE, for safer and faster refuelling.

Precooler Solutions for 700 Bar Stations

Temperature Control and Safety

When you go to a hydrogen station, you want to be safe. Refueling at 700 bar makes a lot of heat. Too much heat can cause problems for you and your car. The hydrogen precooler 700 bar helps stop this from happening. It cools the hydrogen gas before it goes into your tank. The gas can get as cold as -40°C. This cooling step protects your car’s tank and the station’s machines.

You can see how important temperature control is by looking at what stations do:

The hydrogen precooler 700 bar uses special microchannel heat exchangers to cool hydrogen fast.

Cooling the gas first helps stop the Joule-Thomson effect, which can make hydrogen get hotter than 85°C.

The system keeps hydrogen at a safe temperature and lowers the chance of damage or accidents.

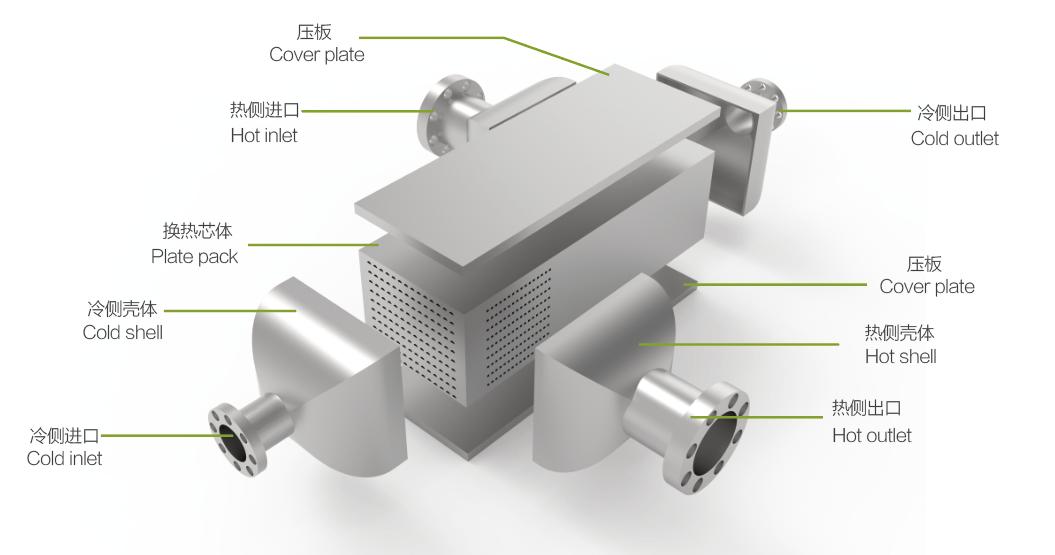

SHPHE is a leader in this area. Their Printed Circuit Heat Exchanger (PCHE) technology gives you good temperature control. The PCHE is small and fits easily in new stations. This saves space and makes it easy to install. You get safer refueling every time.

Fast and Reliable Refueling

You want to fill your tank fast and get going. The hydrogen precooler 700 bar helps make this happen. It cools the hydrogen so you can refuel at high pressure without waiting long. This technology works for cars, trucks, and buses.

Let’s see how heat exchangers like the PCHE from SHPHE help stations work better:

Feature | Description |

|---|---|

Compact Design | 85% smaller than old shell-and-tube exchangers, so stations can be set up in more ways. |

High-Pressure Capability | Handles up to 1,250 bar, which is great for 700 bar hydrogen stations. |

Installation Efficiency | Always put above ground, so building is easier and costs less. |

Refuelling Efficiency | Lets you refuel one after another, so you wait less. |

The PCHE is strong and welded together, so it can handle high pressure. You get quick and reliable refueling every time. The system keeps cooling all the time, so many vehicles can refuel with no breaks.

You also get these benefits:

The hydrogen precooler 700 bar saves space and lowers installation costs.

It works at high pressure, so you fill up fast.

The system helps with both making and delivering hydrogen, so everything runs better.

Note: If you pick a station with SHPHE’s PCHE technology, you get the best safety, speed, and reliability for your hydrogen car.

With these new solutions, hydrogen stations can serve more people and give you a better refueling experience every time.

Benefits for Operators and Users

Station Efficiency and Throughput

Hydrogen stations need to work fast and well. Using a 700 bar hydrogen precooler helps the whole station run better. SHPHE’s technology helps both owners and people who refuel. Here are some ways these stations get better:

Changing the cooling from 15 °C to 10 °C can save energy by 2.86% to 9.43% for each fueling.

If a station sells 180 kg of hydrogen daily, energy use drops by 1.4% to 5.5%.

Bigger stations selling 360 kg a day can save 2.9% to 8% energy.

These numbers mean stations make more hydrogen with less energy. More cars and trucks can refuel each day. This helps the hydrogen station market grow. Using less power is good for the environment. Faster refueling means you wait less. The system becomes more reliable for everyone.

User Experience and Safety

You want refueling to be safe and easy. SHPHE uses strong designs like OptiBondTM diffusion welding in their heat exchangers. This makes the system tough. Both cool and warm sides can handle high pressure. You do not need extra pressure relief valves. This lowers the chance of leaks or accidents.

Stations with these features give you safer refueling. The system keeps hydrogen at the right temperature. Your car’s tank stays safe. You do not worry about overheating or long waits. The hydrogen station market cares about safety and speed. SHPHE’s technology gives you both.

Tip: Pick stations with advanced cooling for the best refueling.

Trends in Hydrogen Refuelling Stations

Market Growth and Capacity

The hydrogen fueling station market is getting bigger fast. This happens because of new technology and help from governments. More stations now use 700 bar systems for quicker refueling. There is also a move toward dual-pressure stations. These stations can fill up cars, buses, and trucks. The global hydrogen fueling station market is changing as more people pick hydrogen for clean travel.

Many stations use 700 bar for quick refueling.

Dual-pressure stations work for many vehicles.

Government help makes the market grow.

350 Bar vs. 700 Bar Competition

You might wonder how 350 bar and 700 bar stations are different. Most new stations use 700 bar for modern cars. You get faster refueling and can drive farther. The table below shows how 700 bar and 350 bar compare:

Feature | 700 Bar | 350 Bar |

|---|---|---|

Refueling Time | Faster refueling | Slower refueling |

Driving Range | Longer trips | Shorter trips |

Vehicle Type | New passenger cars | Buses, trucks, older cars |

Industry Standard | New standard | Used more often |

More car makers build cars for 700 bar stations. The market grows as people want fast refueling and longer drives.

Integration of Digital Monitoring

Digital monitoring is now used in many hydrogen stations. Sensors and smart systems check temperature and pressure. This makes refueling safer and more steady. SHPHE uses advanced PCHE technology. Their heat exchangers work well with digital tools. You get better safety and stations work better. As the market grows, more stations will use digital monitoring and PCHEs for best results.

PCHEs work with high pressure and cold gas.

Digital tools help stations run well.

SHPHE gives strong technology to the market.

Future Outlook for Hydrogen Precooler 700 Bar

Scaling Up Infrastructure

More people are starting to use hydrogen vehicles now. This means more hydrogen stations are needed everywhere. Building these stations takes many different parts working together. Here is a table that shows what is needed for a good network:

Infrastructure Component | Description |

|---|---|

Production Facilities | You need places to make hydrogen, like electrolysis plants or steam-methane reformers. |

Storage Systems | Safe and efficient storage is important. You use both stationary and mobile systems. |

Transportation Networks | Moving hydrogen from where you make it to where you use it is key. |

Safety Mechanisms | You must keep everything safe and reliable. |

Grid Integration | Linking hydrogen with renewable energy makes the system stronger and more efficient. |

There are some problems when building more stations. It costs a lot of money to build new stations. You also need special technology for high-pressure hydrogen. Some places, like California, do not have as many stations as they wanted. This makes it harder for people to find a place to refuel.

Some areas do not have enough stations, which slows down hydrogen car growth. For example, California wanted 200 stations by 2025 but may only have 87.

Innovations Ahead

New ideas are changing how you refuel hydrogen cars. Cryo-compressed hydrogen (CcH2) systems are becoming more common. These systems cost less and do not need extra parts like buffers or heat exchangers. Companies like Cryomotive have made truck tanks that hold more hydrogen at a higher density. This lets you drive farther before you need to refuel.

Scientists are working on better cooling technology. SHPHE leads with printed circuit heat exchangers (PCHEs). These exchangers are small, strong, and work very well. They help keep hydrogen cool during refueling. New designs use hybrid channels and better materials to save energy and make things safer. You might also see new tools like vortex tubes and turbo-expanders soon.

The hydrogen station market will keep growing as these new ideas make refueling safer, faster, and more reliable. You will get better technology and more places to fill up your hydrogen vehicle.

You can see how hydrogen precooler 700 bar technology helps refueling stations. SHPHE uses advanced PCHE heat exchangers to make stations safer and work better. These exchangers help make hydrogen and keep the system small. You get to refuel quickly and stay safe. The table below shows how PCHE helps stations grow for a long time:

Feature | Description |

|---|---|

High Efficiency and Compactness | Delivers maximum heat exchange in a lightweight, space-saving design—ideal for urban stations. |

Pre-Cooling Precision | Cools hydrogen to -40°C before dispensing, mitigating compression heat and ensuring compliance. |

Scalability for Heavy-Duty Use | Modular design allows integration into cascade storage systems, supporting high-flow rates for trucks. |

New ideas will give you more places to fill up and help clean transportation get bigger. You can expect hydrogen precoolers to be important for travel in the future.

FAQ

What does a hydrogen precooler do at a refueling station?

A hydrogen precooler makes the gas cold before it goes into your car’s tank. This helps keep your tank safe. You can fill up faster. SHPHE uses smart technology to make sure this works well.

Why is 700 bar important for hydrogen cars?

At 700 bar, you get more hydrogen in your tank. This lets you drive farther. Most new hydrogen cars use 700 bar stations for better driving.

How does SHPHE’s PCHE help with safety?

SHPHE’s Printed Circuit Heat Exchanger keeps hydrogen at the right temperature. This lowers the chance of overheating. You stay safe when you fill up.

Can I use a 700 bar station for any hydrogen vehicle?

Most new cars use 700 bar stations. Some older cars and buses use 350 bar. Always look at your car’s manual before you refuel.