What Makes a Gasket Free Heat Exchanger Work So Well

A gasket free heat exchanger uses a welded plate design to transfer heat between fluids without the need for gaskets. This type of plate heat exchanger, like the HT-Bloc from Shanghai Plate Heat Exchanger, works by channeling fluids through thin metal plates that are permanently sealed together. The absence of gaskets allows the gasket free heat exchanger to handle high pressures up to 3.2 MPa and temperatures from -20 to 350ºC. These exchangers use strong materials such as stainless steel and titanium, making them ideal for demanding industrial environments. The welded construction ensures a reliable, leak-resistant operation and supports efficient heat transfer.

Feature | Value |

|---|---|

Design Temperature/ºC | -20 to 350 |

Design Pressure/MPa | Up to 3.2 |

Area/m2 | 1.4 to 860 |

Plate Spacing/mm | 8 to 10 |

Plate Thickness/mm | 0.8 to 1.2 |

Gasket Free Heat Exchanger Features

Construction and Materials

A gasket free plate heat exchanger uses a fully welded construction. This design removes the need for gaskets, which are often the weakest part of traditional exchangers. The HT-Bloc welded plate heat exchanger by Shanghai Plate Heat Exchanger is a prime example of this advanced approach. Each plate is welded to the next, forming a strong, leak-resistant barrier that can handle high heat and pressure.

High-quality materials play a key role in the durability and performance of these exchangers. Stainless steel and titanium are common choices. These metals resist corrosion and maintain strength even under extreme heat. Some models use specialized materials like DIABON and SICABON for handling highly corrosive or oxidizing fluids. The table below shows how these materials perform in tough environments:

Material | Application Description | Durability and Corrosion Resistance Evidence |

|---|---|---|

DIABON | Gasket-free plate heat exchanger for heating or cooling of corrosive media | Reliable choice for tough applications, with a focus on economic performance in corrosive environments. |

SICABON | Tube heat exchangers for controlling highly corrosive or oxidizing applications | Optimized solutions that significantly reduce operational costs and minimize risks in processing corrosive media. |

These materials ensure the plate heat exchanger can operate for many years with minimal wear, even when exposed to aggressive chemicals or high temperatures.

Welded Design Benefits

The welded design of a gasket free plate heat exchanger brings several important benefits. By eliminating gaskets, the exchanger can withstand much higher pressures and temperatures. This design also reduces the risk of leaks, which is critical in industrial settings where safety and reliability matter most.

The HT-Bloc welded plate heat exchanger offers measurable advantages. It recovers 10–15% more energy through its cross-counterflow design, leading to better efficiency. Fewer maintenance shutdowns mean longer service life and less downtime. Many welded plate heat exchangers, including the HT-Bloc, come with extended warranties, showing the manufacturer’s confidence in their durability.

A welded plate heat exchanger also simplifies cleaning and maintenance. The absence of gaskets means fewer parts to replace and less chance of failure. This makes the exchanger a smart choice for industries that demand both high heat transfer and low maintenance.

How Gasket Free Plate Heat Exchangers Work

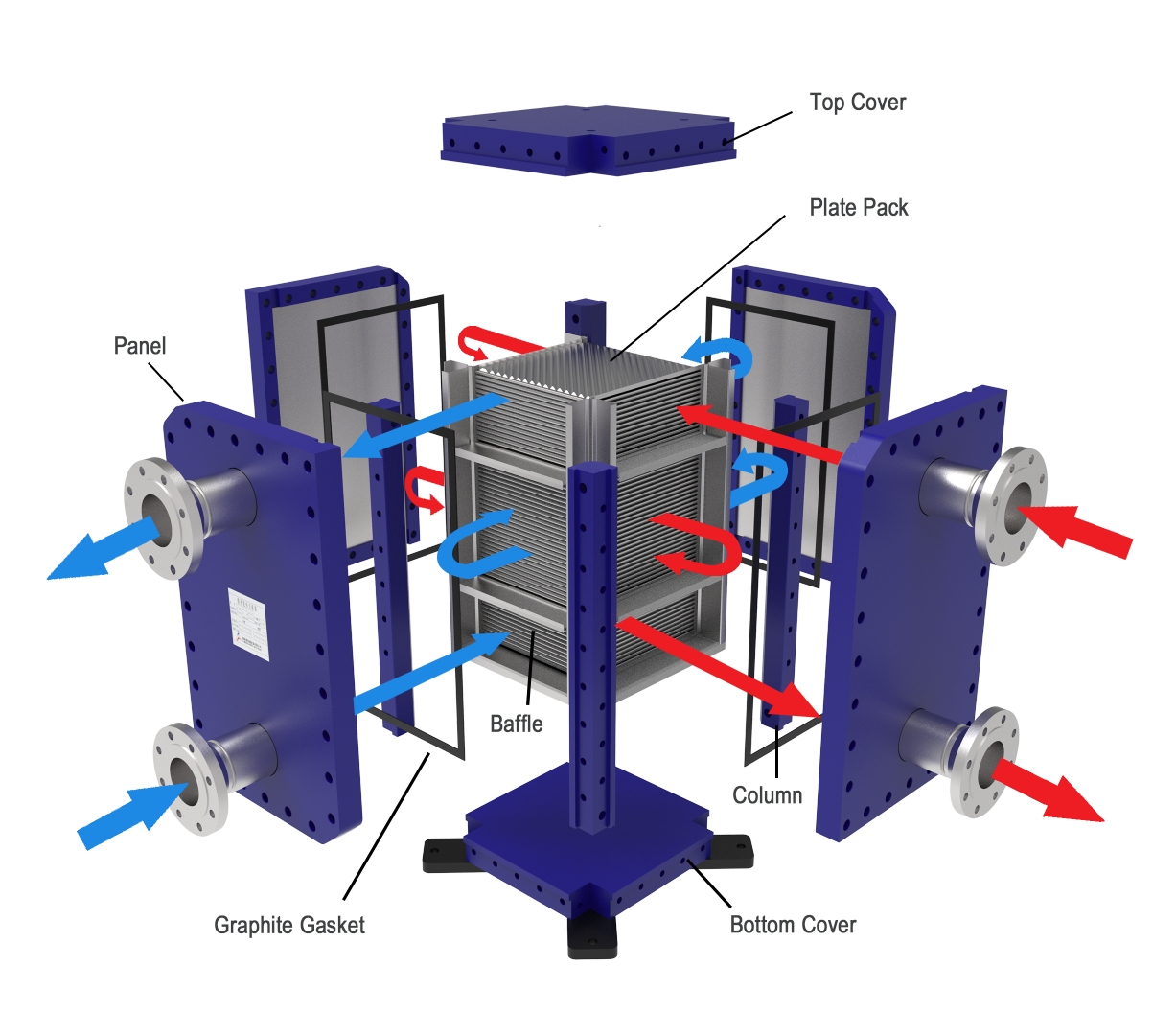

Flow Paths and Heat Transfer

A gasket free plate heat exchanger uses a series of thin metal plates welded together. These plates form channels with narrow gaps. The design creates troughs at right angles to the flow direction. This arrangement gives a large surface area for heat exchange. Fluids move through these channels and stay in close contact with the plates. The result is a rapid transfer of thermal energy.

The corrugated plates inside the exchanger promote turbulent flow. Turbulence increases wall shear stress and helps mix the fluids. This process boosts heat transfer efficiency. In many plate heat exchanger designs, hot and cold fluids flow in opposite directions. This counter-current flow raises the heat transfer coefficient. The HT-Bloc welded plate heat exchanger from Shanghai Plate Heat Exchanger uses this principle to maximize thermal energy transfer.

Researchers have found that adding fins or special corrugations to the plates can improve heat transfer. They also study how fouling affects performance. Fouling can lower the rate of thermal energy transfer. Scientists use experiments to measure heat transfer rate and overall efficiency. They look at clean and fouled conditions to understand how to optimize the exchanger.

An experimental study on panel plate heat exchangers showed that waved channels help control pressure drop. The Darcy friction factor is used to estimate this drop. Understanding flow dynamics is important for improving heat transfer efficiency in these systems.

Sealing and Pressure Resistance

The welded construction of a gasket free plate heat exchanger creates a tight and permanent seal. There are no gaskets between the plates. This design removes the risk of gasket failure and leaks.

Welded plate heat exchangers are constructed without gaskets. Instead, the plates are welded together to create a tight and permanent seal. This design eliminates the risk of gasket failure and potential leaks, making welded plate heat exchangers suitable for applications involving high temperatures, corrosive fluids, and high-pressure conditions.

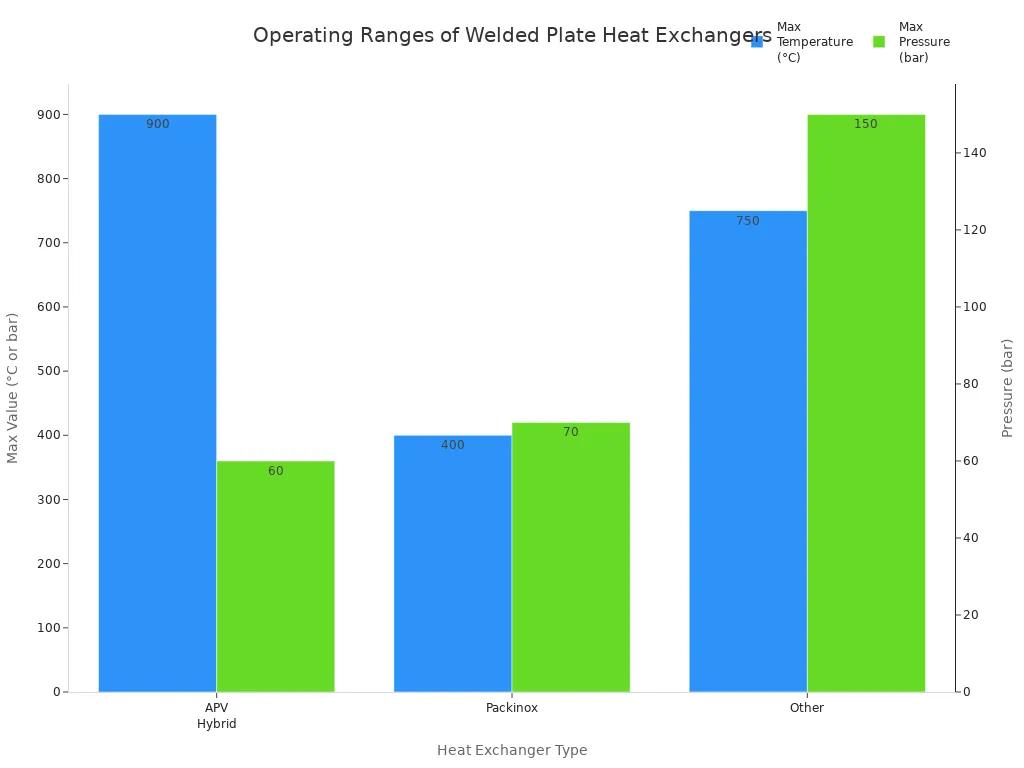

The absence of gaskets allows the exchanger to operate at much higher pressures and temperatures. The HT-Bloc welded plate heat exchanger can handle pressures up to 3.2 MPa and temperatures from -20°C to 350°C. Other welded plate heat exchangers can reach even higher ranges, as shown in the table below:

Heat Exchanger Type | Temperature Range | Pressure Range |

|---|---|---|

APV Hybrid | −200 °C to 900 °C | up to 60 bar |

Packinox | up to 400 °C | up to 70 bar |

Other | −270 °C to 750 °C | up to 150 bar |

This strong sealing makes the plate heat exchanger ideal for handling corrosive fluids and harsh industrial environments. The welded design also supports long-term reliability and safety.

The HT-Bloc welded plate heat exchanger, available from Shanghai Plate Heat Exchanger, demonstrates these advantages. Its robust construction and advanced flow path design ensure efficient thermal energy transfer and high operational safety. For more details, you can visit the HT-Bloc product page.

Performance Advantages

Efficiency and Reliability

Gasket free heat exchangers deliver high thermal performance in industrial settings. Their compact design and welded construction allow for rapid heat transfer between fluids. These exchangers often require less pumping power, which helps reduce energy consumption. The sealed plates prevent leaks and maintain efficiency over time. Gasketed plate heat exchangers may lose efficiency as gaskets age or wear out. Gasket free models, such as the HT-Bloc, keep their performance stable for longer periods.

Brazed plate heat exchangers show higher thermal efficiency due to their design.

Gasketed exchangers offer flexibility but may have lower efficiency and more leak points.

Gasket free exchangers need less pumping power for the same heat transfer rate.

Pressure drops are lower in gasket free designs, which boosts operational efficiency.

Long-term reliability is better in gasket free exchangers because their sealed construction prevents fouling.

Maintenance and Cleaning

Maintenance is easier with gasket free heat exchangers. The modular design of the HT-Bloc allows for quick disassembly. Cleaning can be done thoroughly without complex steps. Industries that require strict hygiene benefit from this feature. Several cleaning methods are available:

Cleaning Method | Effectiveness | Advantages and Drawbacks |

|---|---|---|

Clean-in-Place (CIP) | Highly effective for thorough cleaning | Fast, reaches all areas, no disassembly needed |

Chemical Cleaning | Very effective for tough deposits | Needs careful handling, may affect materials |

Mechanical Cleaning | Good for stubborn deposits | May require disassembly, effective physically |

High-Pressure Water Jetting | Removes loosened deposits after chemical cleaning | Requires safety precautions, very effective |

These methods help maintain heat transfer efficiency and extend the life of the exchanger.

Comparison with Gasketed Designs

Gasketed plate heat exchangers face several failure modes. Gasket aging, swelling, and improper installation can cause leaks and performance issues. Gasket free designs remove these risks. The table below shows common failure modes and how gasket free exchangers address them:

Failure Mode | Description | Proposed Solutions |

|---|---|---|

Leakage Issues | Caused by aged gaskets or cracks | Replace gaskets or use gasket free design |

External Media Leakage | Hydraulic hammering or gasket swelling | Re-gasketing or switch to welded construction |

Performance Issues | Material failure due to age or temperature | Regular maintenance or use gasket free exchanger |

Gasket-related Failures | Aging, swelling, improper installation | Gasket free design eliminates these problems |

Gasket free heat exchangers also contribute to energy savings. They enhance heat transfer, minimize fouling, and reduce pressure drops. These factors help industries save energy and maintain stable operations.

Industrial Applications

Power Generation and Metallurgy

Gasket free heat exchangers play a vital role in power generation and metallurgy. These industries need reliable heat transfer solutions to manage high temperatures and pressures. Power plants use heat exchangers to cool turbines and generators. The demand for electricity and renewable energy drives the need for efficient heat management. Metallurgical processes require heat exchangers that can handle fluids with impurities and particles. The welded design of the HT-Bloc exchanger from Shanghai Plate Heat Exchanger meets these needs by providing strong seals and using materials like stainless steel and titanium.

Shell and tube exchangers are important in petroleum and chemical engineering.

Plate exchangers in metallurgy must withstand high heat and handle challenging fluids.

The absence of gaskets in welded designs prevents leaks and supports safety.

The table below shows common industries and their applications for gasket free heat exchangers:

Industry | Application Description |

|---|---|

Power Generation | Cooling turbines and generators, supporting energy efficiency and reliability. |

Metallurgy | Managing high heat levels and fluids with impurities, ensuring process stability. |

Chemical Processing | Heating and cooling process fluids, handling corrosive and high-temperature fluids. |

Food, Pharma, and Offshore Uses

Gasket free heat exchangers also excel in food processing, pharmaceutical manufacturing, and offshore engineering. Food and beverage industries use heat exchangers for pasteurization, sterilization, and cooling. These processes require strict hygiene and stable heat transfer. Pharmaceutical plants rely on exchangers for precise temperature control and contamination prevention. Offshore engineering benefits from the robust design of welded exchangers, which resist corrosion and operate reliably in harsh environments.

The HT-Bloc exchanger is certified to meet international standards, including ISO 9001 and CE. These certifications ensure quality, safety, and environmental protection. The table below highlights key certifications:

Certification | Description |

|---|---|

ISO 9001 | Quality management system standard |

CE | Health, safety, and environmental protection standards |

Offshore applications gain environmental benefits from gasket free heat exchangers. They capture waste heat and pre-heat air, which improves energy efficiency and reduces pollution. The table below summarizes these benefits:

Benefit | Description |

|---|---|

Energy Savings | Captures waste heat, enhances efficiency, and lowers energy use. |

Reduced Pollution | Requires less energy for heating, leading to lower emissions. |

The HT-Bloc welded plate heat exchanger from Shanghai Plate Heat Exchanger is designed for demanding environments. Its modular construction, high-quality materials, and compliance with international standards make it a trusted choice for industries that require reliable heat management.

Gasket free heat exchangers show strong durability, high efficiency, and versatility in many industries. Welded plate designs like the HT-Bloc from Shanghai Plate Heat Exchanger use robust materials and compact layouts to improve heat transfer and reliability. The table below highlights key features and benefits:

Feature | Benefit |

|---|---|

Welded Plates | Prevent fluid leakage, boosting reliability. |

Robust Materials | Withstand harsh conditions, ensuring durability. |

Compact Design | Enhance thermal performance in tight spaces. |

Industrial users value these exchangers for their easy maintenance and ability to handle a wide range of fluids. Important factors when choosing a heat exchanger include heat transfer capacity, flow rate, pressure drop, and material compatibility. Selecting the right solution ensures safe, efficient, and long-lasting heat management.

High thermal efficiency from intricate plate design

Durable and reliable for demanding conditions

Easy maintenance with modular construction

FAQ

What is a gasket free heat exchanger?

A gasket free heat exchanger uses welded plates instead of gaskets to seal fluid channels. This design allows the unit to handle higher pressures and temperatures. It also reduces the risk of leaks and extends the service life.

How does the HT-Bloc welded plate heat exchanger improve efficiency?

The HT-Bloc uses a cross-counterflow design and advanced plate geometry. This setup increases the surface area for heat transfer. As a result, it recovers more energy and operates with less energy loss.

Can the HT-Bloc handle corrosive fluids?

Yes. The HT-Bloc uses high-quality materials like stainless steel and titanium. These materials resist corrosion and maintain strength in harsh environments. This makes the exchanger suitable for chemical, offshore, and industrial applications.

How easy is it to clean and maintain a welded plate heat exchanger?

The modular design of the HT-Bloc allows for easy cleaning. Users can choose from methods like clean-in-place, chemical, or mechanical cleaning. Fewer parts mean less downtime and lower maintenance costs.

Where can I learn more about the HT-Bloc welded plate heat exchanger?

You can visit the HT-Bloc product page for detailed specifications, certifications, and application examples.