A Journey Through the Heat Exchangers Industries Served Globally

Power Generation: Efficiently Energizing the World

The power generation industry relies heavily on heat exchangers to maximize thermal efficiency and ensure operational reliability. These devices are fundamental to converting thermal energy into electricity across both conventional and renewable sources.

Traditional and Nuclear Power Plants

In traditional fossil fuel and nuclear power plants, heat exchangers perform critical functions. Large condensers cool high-pressure steam from turbines, converting it back into liquid water for reuse. This process creates a vacuum that maximizes turbine efficiency. Other heat exchangers, known as feedwater heaters, use residual heat to pre-warm this water before it returns to the boiler. This cycle significantly reduces the fuel required to generate steam, boosting the plant's overall output and economic performance.

Renewable Energy Systems

Renewable energy systems also depend on advanced heat exchanger technology. In Concentrated Solar Power (CSP) plants, shell-and-tube heat exchangers transfer energy from a heated fluid to water, creating the steam needed to drive turbines. Geothermal applications present unique challenges, including corrosive fluids and fluctuating temperatures.

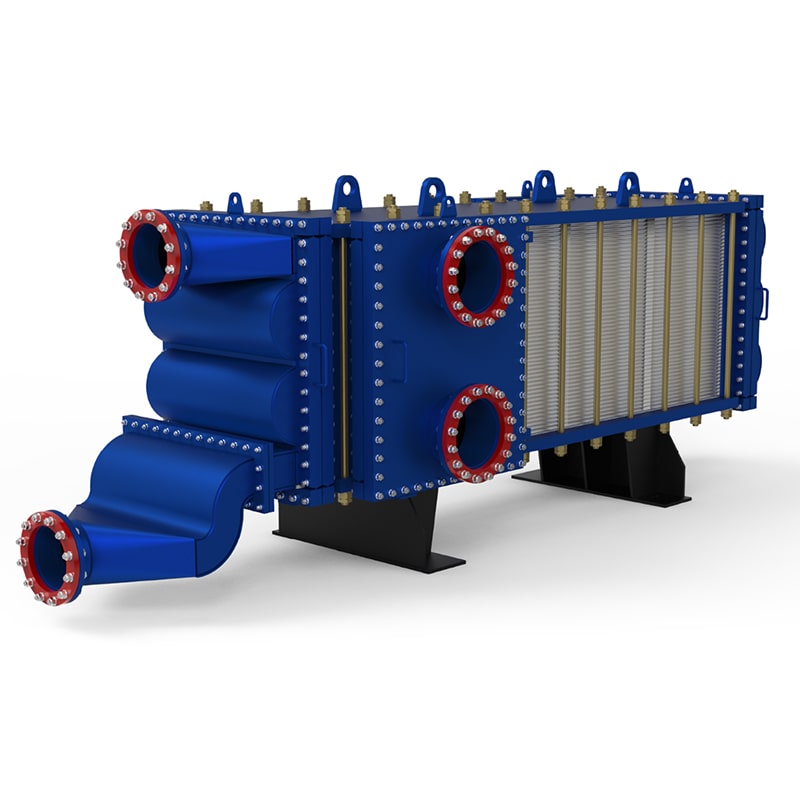

Modern plate heat exchangers address these issues with innovative designs. They use corrosion-resistant materials like titanium and feature compact layouts that simplify installation while maximizing heat recovery from solar collectors or geothermal brines.

These advancements are crucial for harnessing renewable energy efficiently. Key innovations focus on:

·Rapid Response: Plate heat exchangers adjust quickly to the variable loads common in solar and wind power.

·Fouling Resistance: Special plate geometries minimize buildup and reduce maintenance downtime.

·Compact Footprints: Smaller designs are ideal for retrofitting existing facilities and minimizing land use.

Oil & Gas: Fueling Operations from Upstream to Downstream

The Oil & Gas industry operates under some of the world's most demanding conditions. Heat exchangers provide reliable thermal performance to manage these challenges. They are engineered to withstand extreme temperatures, high pressures, and corrosive fluids, making them indispensable from extraction to refining.

Upstream and Midstream Applications

In upstream operations, heat exchangers ensure safety and efficiency. Shell-and-tube designs are common due to their high tolerance for pressure and temperature. They perform several key functions:

·Preheating crude oil before initial separation.

·Cooling compressed natural gas for storage or transport.

·Condensing hydrocarbon vapors during purification.

·Recovering waste heat from hot process streams.

Midstream processes, especially Liquefied Natural Gas (LNG) production, rely on specialized cryogenic heat exchangers. Different liquefaction technologies use specific exchanger types to cool natural gas to -162°C (-260°F).

Key Heat Exchangers in LNG LiquefactionThe choice of heat exchanger is critical for process efficiency. | Liquefaction Technology | Pre-cooling | Main Liquefaction | | :--- | :--- | :--- | | C3MCR / AP-X™ | Core in Kettle | MCHE | | CasCade / Prico | PFHE | PFHE | | DMR | SWHE | SWHE |Key: MCHE (Main Cryogenic Heat Exchanger), PFHE (Plate-fin Heat Exchanger), SWHE (Spiral Wound Heat Exchanger)

Downstream Refining Processes

Downstream refineries use heat exchangers extensively to enhance energy efficiency. The most critical application is the preheat train. Here, a network of heat exchangers transfers thermal energy from hot product streams leaving the distillation column to the incoming cold crude oil. This process preheats the crude oil to approximately 280°C (536°F) before it enters the furnace. This preheating step significantly reduces the furnace's thermal load, which cuts fuel consumption and lowers operational costs.

HVAC & Refrigeration: The Backbone of Climate Control

Heat exchangers are essential components in the HVAC & Refrigeration industry. They provide the climate control that modern life depends on, from residential comfort to industrial-scale cooling. These devices enable efficient heat transfer, which is fundamental to both heating and cooling cycles.

Commercial and Residential Systems

In commercial and residential buildings, heat exchangers drive energy efficiency. Modern commercial systems use Heat Recovery Ventilators (HRVs) and Energy Recovery Ventilators (ERVs) to reduce heating and cooling loads. These systems meet strict efficiency standards by recovering thermal energy from exhaust air.

Minimum Efficiency Standards for Commercial Recovery Ventilators| System Type | Minimum Sensible Recovery Efficiency | Minimum Total Recovery Efficiency | | :--- | :--- | :--- | | HRVs | 85% | N/A | | ERVs | 75% | 80% |

Residential units also benefit from advanced designs. Microchannel heat exchangers, for example, use flat tubes with tiny internal channels. This design dramatically increases the surface area for heat transfer, allowing for more compact and energy-efficient air conditioning units.

Industrial Refrigeration and Cold Chain Logistics

Industrial refrigeration systems rely on robust heat exchangers for large-scale cooling. In facilities using ammonia-based systems, heat exchangers perform several critical functions:

·Condensing high-pressure ammonia vapor back into a liquid.

·Evaporating liquid ammonia to absorb heat and provide cooling.

·Recovering waste heat to improve overall system efficiency.

This technology is also vital for the cold chain, which protects temperature-sensitive goods like food and pharmaceuticals. Heat exchangers ensure precise temperature control during processing, storage, and transport. This capability preserves product quality and safety, preventing spoilage and maintaining the efficacy of medicines.

Chemical Processing: Precision Temperature Control

The chemical industry requires precise temperature control. This control ensures operational safety, process efficiency, and high product quality. Heat exchangers are the primary technology used to manage thermal energy in complex chemical production environments. They enable operators to maintain reaction temperatures within narrow, optimal ranges.

Chemical Synthesis and Reaction Management

Many chemical reactions are either exothermic (release heat) or endothermic (absorb heat). Managing these thermal changes is critical. Plate heat exchangers offer this precision. Their thin, corrugated plates create a large surface area, which enables rapid heat transfer. For exothermic reactions, this efficiency quickly removes excess heat, preventing dangerous temperature spikes and thermal runaway. For endothermic reactions, it guarantees a steady supply of energy to sustain the process.

Chemical synthesis often involves highly corrosive substances. Heat exchangers must withstand these harsh conditions to prevent leaks and ensure a long service life. Engineers select specialized materials to handle these aggressive environments. Common choices include:

·High-performance alloys like Hastelloy®, titanium, and zirconium

·Advanced ceramics such as silicon carbide (SiC)

·Treated materials like impregnated graphite (DIABON®) and PTFE (POLYFLURON®)

·Protective coatings, including epoxy resins and specialized polyurethanes

Solvent Recovery and Waste Heat Utilization

Heat exchangers play a vital role in making chemical processes more sustainable and cost-effective. One key application is solvent recovery. In this process, heat exchangers cool hot solvent vapors, condensing them back into a liquid state. This allows valuable solvents to be collected and reused, reducing raw material costs and environmental emissions.

This process also provides an opportunity for waste heat utilization. The thermal energy captured during solvent condensation is not discarded. Instead, it is transferred to other parts of the plant. This recovered heat can pre-warm raw materials or provide energy for other processes.

This dual-function approach significantly cuts operational costs. It also supports sustainability goals by minimizing waste and energy consumption.

Food & Beverage: Upholding Safety and Quality

The Food & Beverage industry uses heat exchangers to guarantee product safety and maintain consistent quality. These devices provide the precise thermal control needed for processes ranging from pasteurization to brewing, protecting consumers and preserving the sensory attributes of food and drinks.

Pasteurization and Sterilization Processes

Heat exchangers are central to pasteurization. This process eliminates harmful microorganisms by heating products to specific temperatures for a set duration. Plate heat exchangers are highly efficient for this task, especially for liquids like milk. Different methods achieve different shelf-life goals.

| Pasteurization Method | Temperature | Time |

|---|---|---|

| High-Temperature Short-Time (HTST) | At least 72°C (161°F) | 15 seconds |

| Ultra High Temperature (UHT) | 137°C (279°F) | 4 seconds |

For beverages with higher viscosity or particulates, such as pulpy juices, tubular heat exchangers are ideal. Their design prevents blockages and ensures a smooth product flow. This allows for uniform heating and efficient sterilization without damaging the product's texture.

Brewing and Production Line Applications

In brewing, heat exchangers perform critical temperature control functions. After boiling, brewers use them to rapidly cool the hot wort. This quick cooling prepares the wort for fermentation and prevents the growth of unwanted bacteria. During fermentation, shell and tube heat exchangers connected to glycol chillers maintain a consistent temperature. This control is essential for optimal yeast performance and predictable flavor profiles.

Beverage production lines rely on various heat exchanger types to manage heating and cooling needs. Each type serves a specific purpose:

·Plate Heat Exchangers are used for pasteurization and general cooling.

·Tubular Heat Exchangers handle viscous liquids or those with solids.

·Shell and Tube Heat Exchangers are reliable for high-volume applications.

This versatility makes heat exchangers indispensable for creating safe, high-quality beverages.

A Look at All Heat Exchangers Industries Served

Heat exchangers are vital in the transportation sector. They provide critical thermal management for vehicles on land, in the air, and at sea. The automotive, aerospace, and marine sectors are key heat exchangers industries served, each with unique operational demands.

Automotive and Aerospace Applications

In the automotive industry, heat exchangers are essential for performance and comfort. Radiators cool engine fluids to prevent overheating and improve efficiency. For cabin climate control, a heat exchanger transfers thermal energy to heat or cool the air, ensuring passenger comfort. The system works by:

·Circulating hot engine coolant or cold refrigerant through the unit.

·Blowing air across the exchanger's surface to transfer heat.

·Distributing the conditioned air into the cabin.

Aerospace applications demand lightweight and highly efficient solutions. Modern microtube heat exchangers offer superior performance for cooling vital avionics compared to older designs. They also manage temperatures in environmental control systems, which cool and dehumidify cabin air for passenger safety and comfort.

Marine and Shipbuilding Systems

Marine environments present extreme challenges for thermal equipment. Heat exchangers cool a ship's main engine, which increases power output and reduces fuel consumption. They also regulate temperatures for auxiliary systems like HVAC and refrigeration. However, the marine setting is harsh.

Saltwater relentlessly corrodes materials, while marine organisms cause biofouling. This buildup clogs passages and severely reduces thermal efficiency.

Operators face several persistent issues:

Corrosion: Constant saltwater exposure degrades metal components.

Biofouling: Algae and barnacles accumulate on surfaces, impeding heat transfer.

Scaling: Mineral deposits form inside the unit, reducing flow and efficiency.

These factors make robust design and material selection critical in the heat exchangers industries served by maritime applications.

The New Frontiers for Heat Exchangers in 2025

Heat exchanger technology is expanding into high-growth sectors. These new applications address modern challenges in energy consumption, sustainability, and advanced manufacturing. The technology's adaptability is driving innovation in data centers, green hydrogen, and electric vehicles.

High-Density Data Center Cooling

High-density data centers generate immense amounts of waste heat. Heat exchangers capture this thermal energy for reuse, a process known as heat recovery. Instead of rejecting heat into the environment, these systems repurpose it for other facility needs. This approach significantly lowers energy consumption and reduces greenhouse gas emissions.

High-capacity thermal recovery heat exchangers transfer energy from the data center's cooling loop to the facility's process hot water loop. This heated water can then supply energy for office heating, air handlers, and even snow melt systems.

Green Hydrogen Production and Storage

Green hydrogen production relies on electrolysis, a process that generates significant excess heat. High-efficiency heat exchangers are critical for managing these temperatures. They cool the electrolyzer stacks, which maintains optimal performance and extends equipment lifespan. This efficient cooling delivers several key benefits:

·Maximizes the efficiency of electrolysis for increased hydrogen output.

·Reduces the total energy required for the production process.

·Lowers operating costs through optimized energy recovery.

·Ensures long service life in high-pressure, corrosive environments.

EV Battery Thermal Management

Electric vehicle (EV) batteries require precise temperature control for safety and longevity. Advanced heat exchangers are essential components of an EV's battery thermal management system. Liquid cooling systems use heat exchangers to maintain the battery within its ideal temperature range. This prevents performance loss and protects against thermal runaway. Modern designs also incorporate special properties that reduce deposit buildup and prevent corrosion, further enhancing the battery pack's performance and lifespan.

Heat exchangers are foundational to modern industry, driving efficiency and enabling innovation. Their impact is clear across established and emerging sectors.

·They remain indispensable in core industries like Power, Oil & Gas, and HVAC.

·The technology's role is expanding into high-growth areas, including data centers and electric vehicles.

·Advancements across all heat exchangers industries served are central to achieving 2025 sustainability goals.

FAQ

What are the most critical industries for heat exchangers?

Power Generation, Oil & Gas, and HVAC are primary sectors. The heat exchangers industries served rely on this technology for operational efficiency, safety, and energy recovery in their core processes.

Why are heat exchangers important for new technologies?

They provide essential thermal management for high-growth sectors. This includes cooling data centers, producing green hydrogen, and managing EV battery temperatures to ensure performance and safety.

How are materials chosen for heat exchangers?

Engineers select materials based on the application's demands. Key factors include operating temperature, system pressure, and fluid corrosiveness to guarantee durability and optimal performance.