Company

Brief Introduction

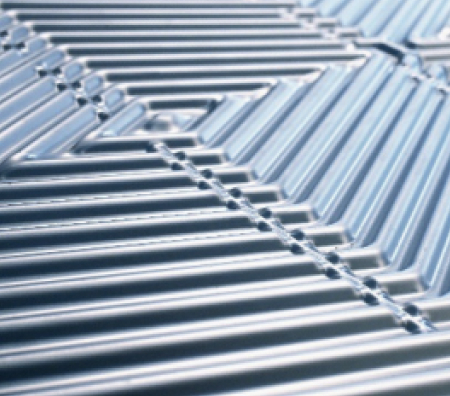

Shanghai Heat Transfer Equipment Co., Ltd. (SHPHE in short) is specialized in design, manufacturing, installation and service of plate heat exchangers.

With advanced engineering and manufacturing technology, comprehensive heat exchanger expertise and rich service experiences, SHPHE dedicates to supply quality plate heat exchangers to various clients worldwide in oil and gas, chemical, power plant, bio-energy, metallurgy, marine, HVAC, mechanical manufacturing, paper & pulp, steel, etc.

SHPHE remains committed to driving industry progress through continuous technological innovation. By partnering with leading companies at home and abroad, SHPHE aims to become a top-tier provider of high-quality solutions in the heat exchange industry, both in China and internationally.

-

2005

FOUNDED IN 2005

2005

FOUNDED IN 2005 -

16+

MORE THAN 16 PRODUCTS

16+

MORE THAN 16 PRODUCTS -

20+

EXPORTED COUNTRIES

20+

EXPORTED COUNTRIES -

20000㎡

FACTORY AREA

20000㎡

FACTORY AREA

Global Footprint

-

canada

-

USA

-

Jamaica

-

Venezuela

-

Brazil

-

RUSSIA

-

china

-

MALAYSIA

-

Singapoare

-

Indonesia

-

AUSTRALIA

-

Norway

-

Mauritius

-

France

-

Germany

-

Romania

-

Turkiye

-

Greece

-

Iran

-

UAE

Customers

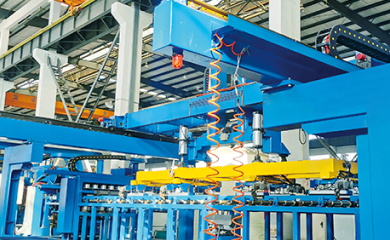

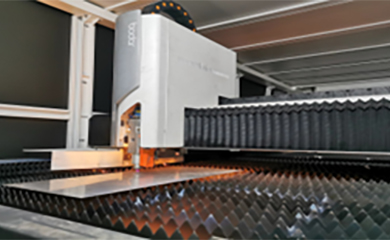

Facilities

Concepts of R&D

-

Listening to Nature

Every researcher draws inspiration from nature’s energy transfer, applying biomimicry principles to meet customer requirements while maximizing safety and energy efficiency. Our latest wide-channel welded plate heat exchangers improve heat transfer efficiency by 15% compared to traditional models. By studying natural energy transfer phenomena—such as how fish reduce drag while swimming or how ripples transfer energy in water—we integrate these principles into product design. This combination of biomimicry and advanced engineering pushes the performance of our heat exchangers to new heights, fully harnessing the wonders of nature in their design.

-

Minimizing Energy Consumption

At the same heat exchange capacity, SHPHE’s removable plate heat exchangers are designed to use the least amount of energy. From research and development to design, simulation, and precision manufacturing, we ensure optimal product performance. SHPHE offers over 10 series of top-tier energy-efficient products, including models with over 350 corner holes at the highest efficiency level. Compared to 3rd-level energy-efficient plate heat exchangers, our E45 model, processing 2000m³/h, can save approximately 22 tons of standard coal annually and reduce CO2 emissions by around 60 tons.

-

Customized

Product development can be tailored to meet the specific needs of users, ensuring a high degree of customization. We work closely with clients to gather detailed insights into their needs and expectations, allowing us to tailor our product development process accordingly. Throughout the research and development design stage, we employ cutting-edge technologies and methodologies to ensure that our products are engineered to the highest standards. We conduct rigorous testing and analysis to validate the design and make necessary adjustments to optimize performance. This attention to detail ensures that our products can withstand extreme pressures and temperatures while maintaining efficient heat transfer.

-

Integrate Digital Technologies

SHPHE has integrated modern digital technologies such as cloud computing, big data, and the internet to create a digital service platform focused on both manufacturing and services. This platform offers smart, comprehensive heat transfer solutions that make customer operations safer, more efficient, and intelligent. With a dedicated research and development team, SHPHE has developed energy-saving technologies that improve energy efficiency. The company has successfully launched several large-scale plate heat exchangers that meet China’s top energy efficiency standards, playing a key role in advancing the country's Carbon Peak and Carbon Neutrality strategy.

-

2005-2025Shanghai Heat Transfer

2005-2025Shanghai Heat Transfer -

2024Obtain the Industrial Pipeline Installation (GC2) certificate for the sub project of the installation, repair, and renovation permit for pressure bearing special equipment

-

2023Obtain safety registration certificate for plate heat exchanger A1-A6 units

Successfully developed, designed, and manufactured an acrylic tower top condenser with a heat exchange area of 7300 square meters per unit

-

2022Successfully developed, designed, and manufactured a pressure resistant 9.6MPa built-in plate heater for the stripping tower

-

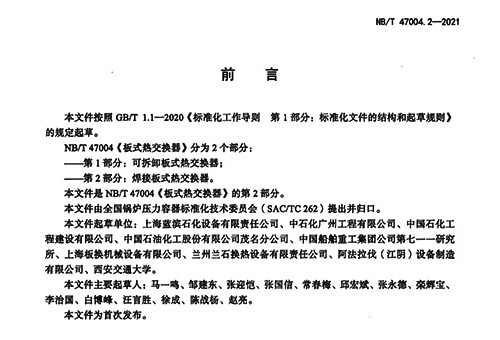

2021Participated in drafting the National Energy Industry Standard (NB/T 47004.2-2021) - Plate Heat Exchanger Part 2: Welded Plate Heat Exchanger

-

2020Obtain the membership certificate of China Urban Heating Association

-

2019Obtained the energy-saving registration certificate for plate heat exchangers, making it the manufacturer with the highest number of first level energy efficiency certification plate types among the first eight applicants;

The first domestic project to complete the localization development of large-scale plate heat exchangers for offshore oil platforms

-

2018Obtain the HTRI membership certificate from the American Heat Transfer Association;

Obtained the high-tech enterprise certificate in 2018

-

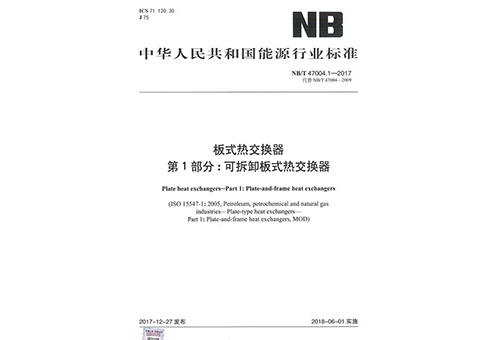

2017 ParticipatParticipated in drafting the National Energy Industry Standard (NB/T 47004.1-2017) - Plate Heat Exchanger (Part 1: Removable Plate Heat Exchanger)

-

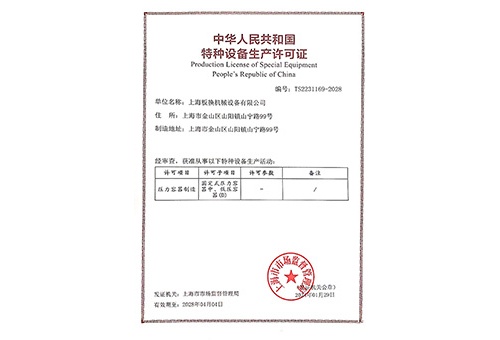

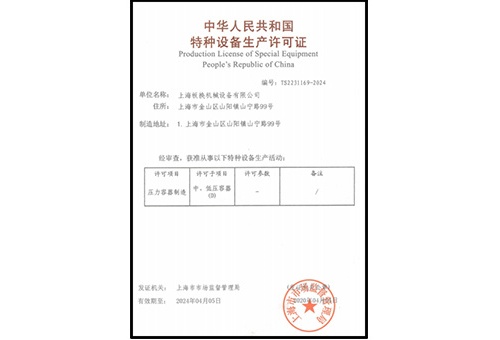

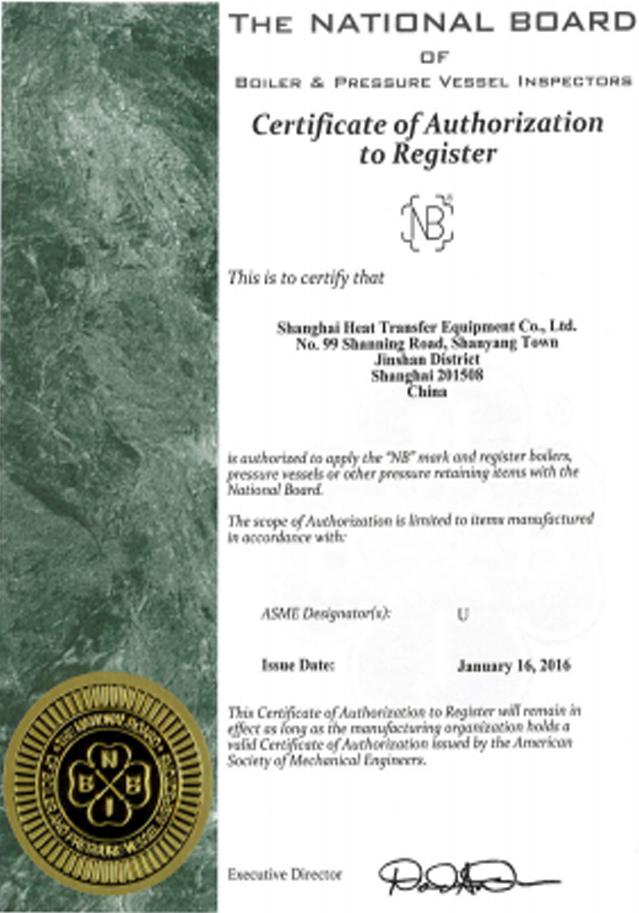

2016Obtained the Special Equipment Manufacturing License (Pressure Vessel) of the People's Republic of China;

Obtain the membership certificate of the Heat Exchange Subcommittee of the National Boiler and Pressure Vessel Standardization Technical Committee

-

2015The first domestically developed vertical wide channel welded plate heat exchanger applied in the alumina industry;

Successfully developed and designed a high-pressure plate heat exchanger with a pressure of 3.6MPa

-

2014Successfully developed plate air preheaters for natural gas hydrogen production, tail gas treatment, and other applications;

The first domestically developed flue gas heat exchanger successfully applied to steam condensing boiler systems

-

2013Successfully developed and applied plate type dehumidification devices for inert gas storage systems in ocean going oil tankers and chemical tankers, and completed domestic manufacturing for the first time;

-

2011Capable of manufacturing civil nuclear safety equipment (plate heat exchangers) and providing plate heat exchange equipment for nuclear power projects such as CGN, China Nuclear Power, and Pakistan;

-

2009Obtained Shanghai High tech Enterprise Certificate and passed ISO9001 system certification

-

2007Mass production of detachable plate heat exchangers;

-

2006Mass production of wide channel welded plate heat exchangers

-

2005business formation

Need more information ?

contact