Leakage free air preheater picks that stop waste now

Leakage free air preheater solutions from top bran...

More

An air preheater is a critical component in steam power plants, significantly enhancing thermal efficiency and reducing fuel consumption. By recovering waste heat from flue gases to preheat combustion air, it ensures optimal boiler performance. Studies show that integrating an air preheater can improve plant efficiency by 5–10%, directly lowering operational costs and emissions. For instance, power plants using air preheaters report fuel savings of up to 15%, making them indispensable for modern energy systems.

The benefits of air preheaters extend beyond efficiency gains. They mitigate corrosion and fouling in boilers by maintaining optimal combustion temperatures, extending equipment lifespan. Data from the U.S. Department of Energy confirms that air preheaters reduce NOx emissions by 10–20%, aligning with environmental regulations. Leading manufacturers like Howden and GE offer advanced designs, including rotary and tubular preheaters, tailored for high-capacity plants. With global demand for energy-efficient solutions rising, investing in an air preheater ensures long-term profitability and sustainability for power generation facilities.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Leakage free air preheater solutions from top bran...

More

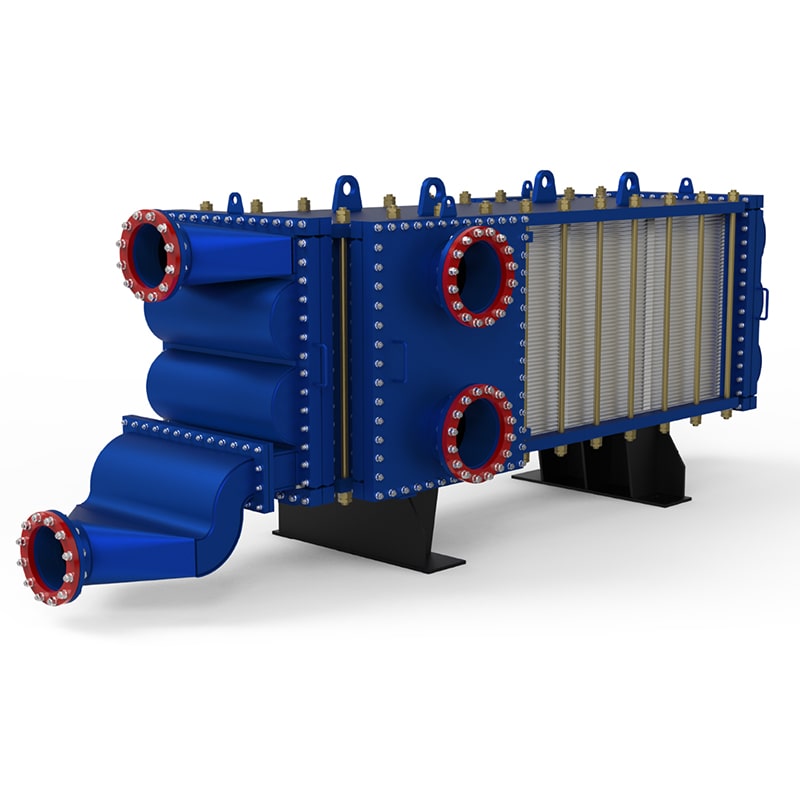

Compare top steam heat exchanger suppliers and pro...

More.jpg)

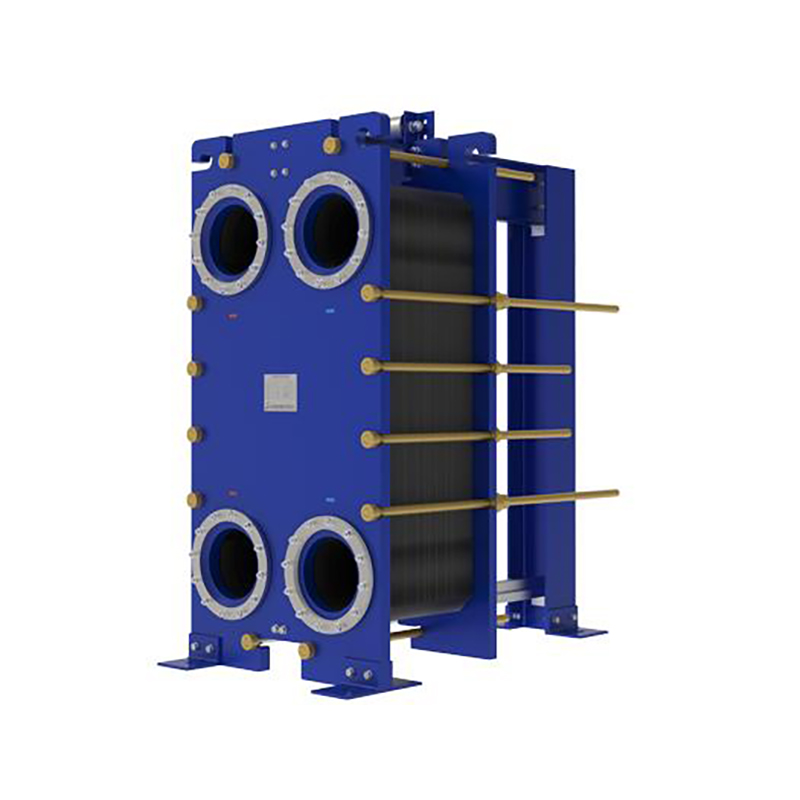

Plate air preheaters transform industrial processe...

More

Factories in 2025 rely on advanced gasketed heat e...

More

Advanced heat exchanger solutions like the TP Weld...

More

Shanghai Plate Heat Exchanger stands at the forefr...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

John Smith

Mechanical EngineerThe air preheater significantly improved our plant's efficiency by recovering waste heat. Highly recommended for steam power plants!

Emily Johnson

Plant OperatorDurable and low-maintenance design. The air preheater reduced fuel consumption in our power plant. A solid investment.

Robert Brown

Thermal Systems SpecialistExcellent performance in preheating combustion air, leading to better boiler efficiency. Perfect for large-scale steam power applications.

Lisa Davis

Project ManagerEasy integration with existing systems and noticeable energy savings. Our plant's emissions dropped after installation.