How Heat Exchanger Heating Enhances Energy Efficiency in Buildings

Heat exchanger heating in HVAC systems boosts ener...

More

An air to air heat exchanger, also known as an air exchanger or energy recovery ventilator (ERV), is a mechanical ventilation device designed to improve indoor air quality while significantly reducing energy costs associated with heating and cooling. It operates by transferring heat and, in some models, moisture between two separate airstreams: the outgoing stale indoor air and the incoming fresh outdoor air. This core function allows buildings to maintain a continuous supply of fresh, filtered air without the massive energy penalty typically incurred by simply exhausting conditioned air and bringing in untreated outside air. These systems are fundamental components in modern, tightly-sealed buildings—including residential homes, commercial offices, industrial facilities, and data centers—where natural ventilation is insufficient. By recovering energy that would otherwise be wasted, they address the critical conflict between the need for ventilation and the desire for energy conservation. The market offers various types, primarily Energy Recovery Ventilators (ERVs), which transfer both heat and moisture, and Heat Recovery Ventilators (HRVs), which primarily transfer only sensible heat. Their adoption is driven by stringent building codes, green building certifications like LEED, and a growing consumer focus on health, efficiency, and sustainability. According to industry analyses from markets like MarketsandMarkets, the global energy recovery ventilation market is projected to experience substantial growth, underscoring their increasing importance in building climate control strategies.

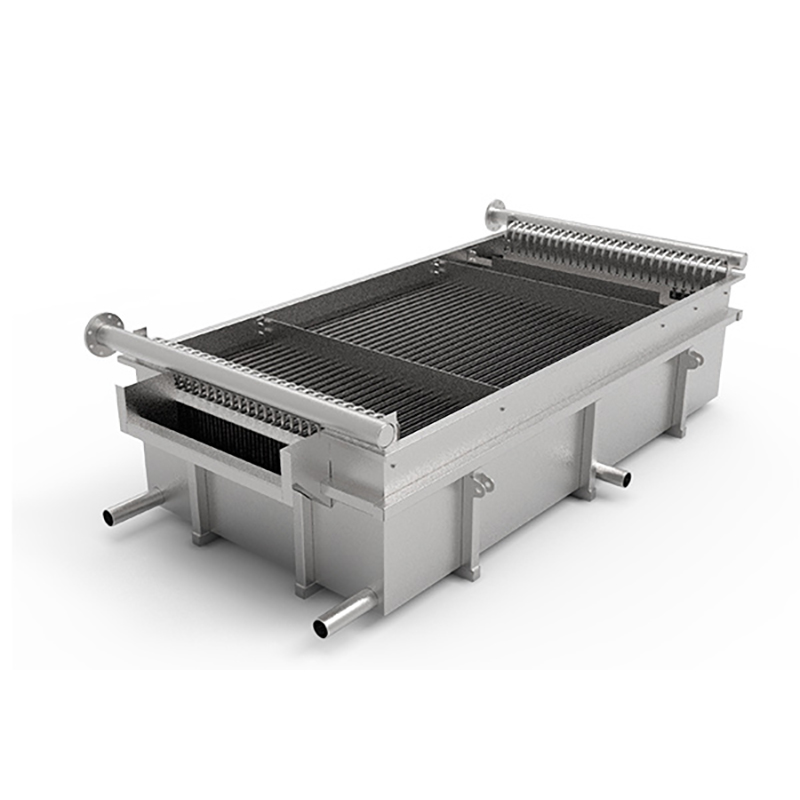

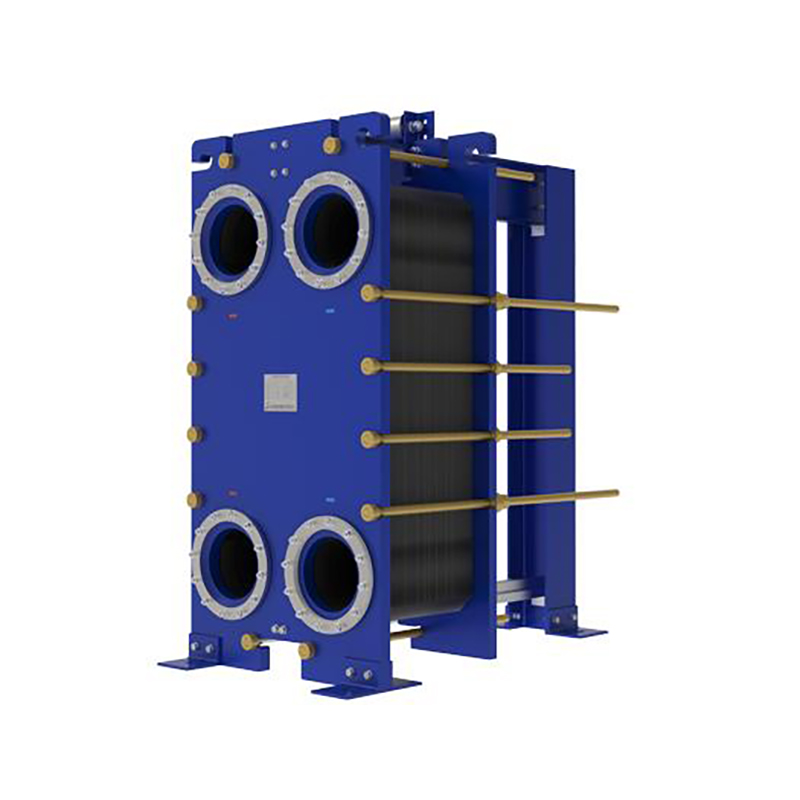

The operational principle of an air to air heat exchanger is based on the efficient transfer of thermal energy through a core, the most common and efficient type being a cross-flow plate heat exchanger. This core is constructed from numerous thin plates of a conductive material, such as aluminum or specialized polymers, which create alternating channels for the two airstreams to pass through without mixing. During winter operation, the warm, moist indoor air being exhausted from the building passes through one set of channels. Simultaneously, cold, dry outdoor air is drawn in through the adjacent channels. The temperature difference drives heat energy through the plates from the warmer exhaust air to the colder supply air, pre-warming the incoming fresh air before it enters the building's heating system. In summer, the process reverses: the cool indoor air cools down the plates, which in turn extract heat from the hot incoming outdoor air, pre-cooling it. ERVs include an additional capability: certain plate materials or embedded membranes allow water vapor to be transferred along with the heat, helping to balance humidity levels by humidifying incoming dry air in winter and dehumidifying humid summer air. Critical components like two fans (for supply and exhaust air), filters to clean both airstreams, and a control system work in unison. Data from manufacturer performance specifications, such as those from industry leaders like RenewAire or Zehnder, show that modern units can achieve sensible recovery efficiencies exceeding 90% and total recovery efficiencies (including latent) of 60-80%, making them exceptionally effective at conserving energy and maintaining comfortable indoor conditions year-round.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Heat exchanger heating in HVAC systems boosts ener...

More

Factories in 2025 rely on advanced gasketed heat e...

More

Advanced heat exchanger solutions like the TP Weld...

More

Shanghai Plate Heat Exchanger stands at the forefr...

More

Modern pillow plate heat exchangers achieve higher...

More

Industrial users gain significant value from a gas...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

Michael Chen

HVAC EngineerThe efficiency of this air to air heat exchanger is outstanding. It has significantly reduced our building's energy consumption for climate control while maintaining excellent air quality. The build quality is robust and installation was straightforward with the provided manual.

Sarah Johnson

Plant ManagerWe installed several units in our manufacturing facility for heat recovery. The performance has been exceptional, capturing waste heat from our processes and pre-heating incoming fresh air. This has led to substantial cost savings on our heating bills. Highly reliable product.

David Rodriguez

Facility DirectorA very effective system for improving ventilation and energy recovery in our large office complex. Air quality has noticeably improved for occupants. Took off one star as the initial setup required some technical expertise beyond a standard contractor, but the supplier support was excellent.

Emily Williams

Sustainability ConsultantI specify these heat exchangers for clients aiming for green building certifications. Their high thermal efficiency and low pressure drop make them a perfect fit for energy-efficient designs. The data provided for energy modeling is accurate and the real-world performance matches the specs perfectly.