5 key roles of plate heat exchanger gaskets.

Plate heat exchanger gaskets perform 5 key roles: ...

More

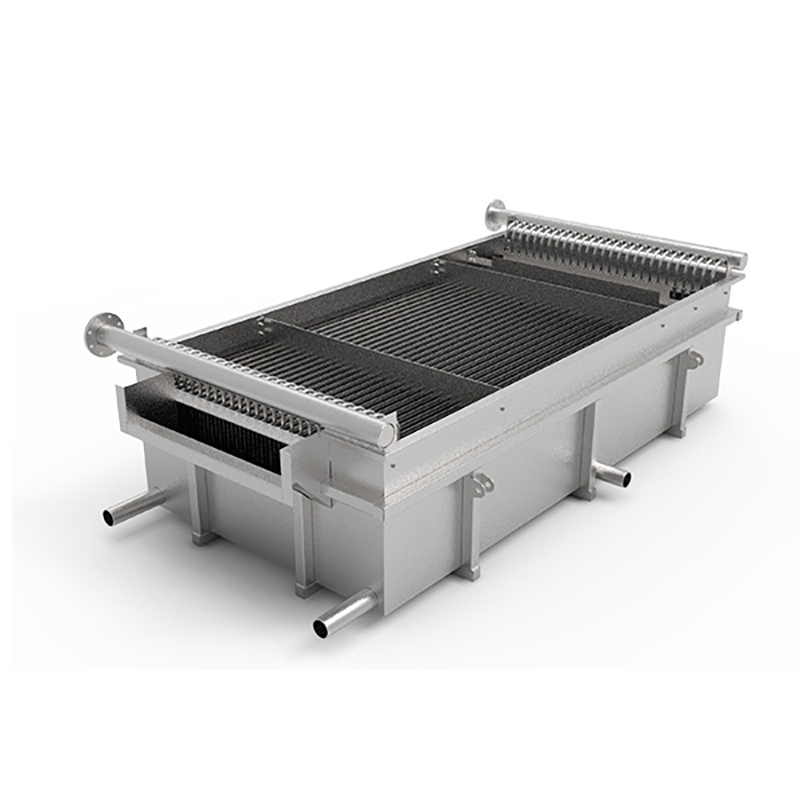

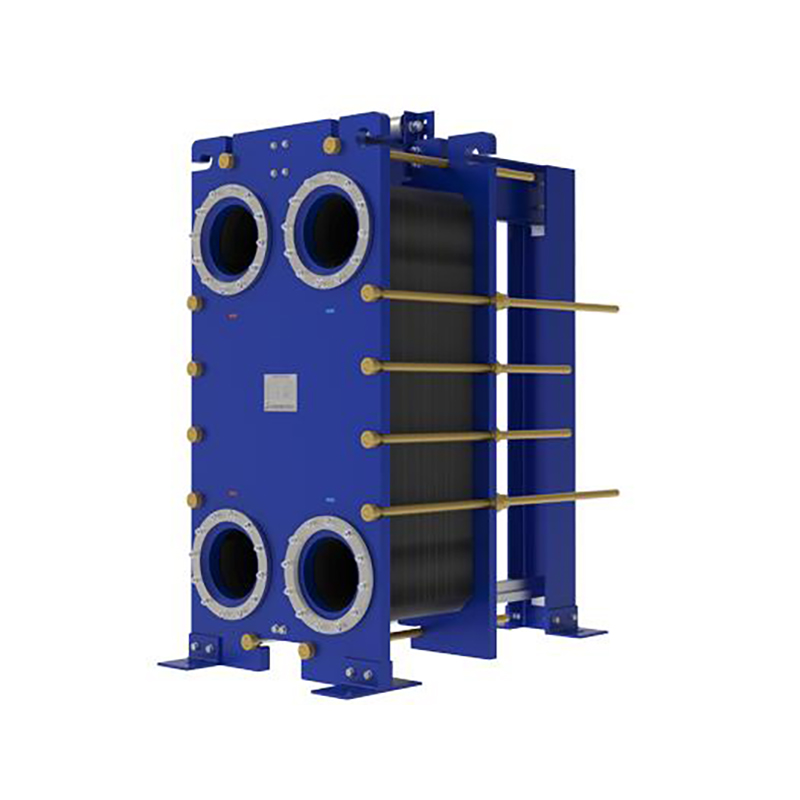

Ammonia heat exchangers are critical components in industrial refrigeration and cooling systems, specifically designed to transfer heat using ammonia (NH3) as the refrigerant. These devices facilitate efficient heat exchange between ammonia and other fluids, such as water or air, in applications ranging from food processing and cold storage to chemical manufacturing. Their robust construction ensures reliability under high-pressure and low-temperature conditions, making them indispensable in large-scale industrial settings where energy efficiency and operational safety are priorities. With advancements in materials and design, modern ammonia heat exchangers optimize thermal transfer while minimizing environmental impact, aligning with global regulations on refrigerant use. Industries rely on them for maintaining precise temperature control, reducing operational costs, and enhancing system longevity. This introduction covers their fundamental role, highlighting why they are a preferred choice for heavy-duty cooling tasks.

An ammonia heat exchanger is a specialized heat transfer device engineered for systems utilizing ammonia refrigerant, which is known for its excellent thermodynamic properties and low environmental impact compared to synthetic alternatives. These exchangers operate by allowing ammonia to absorb heat from one medium and release it to another, typically through a shell-and-tube, plate, or finned design. In industrial contexts, they are integral to processes like freezing, chilling, and condensation. For instance, in food processing plants, ammonia heat exchangers maintain temperatures as low as -40°C to preserve perishable goods, with thermal efficiency rates often exceeding 90% based on industry data. Real-world applications include their use in large cold storage warehouses, where they enable energy savings of up to 20-30% compared to traditional Freon-based systems, as reported by HVAC studies. Manufacturers like Alfa Laval and GEA provide models with corrosion-resistant materials (e.g., stainless steel) to handle ammonia’s reactive nature, ensuring durability and compliance with safety standards such as ASME and PED. Performance metrics show that these units can achieve heat transfer coefficients of 500-1000 W/m²K, depending on design and flow conditions, making them highly effective for high-capacity cooling demands. Their design also minimizes refrigerant charge, reducing leakage risks and operational costs, which is critical given ammonia’s toxicity at high concentrations.

The advantages of ammonia heat exchangers stem from ammonia’s inherent properties and advanced engineering designs. Firstly, ammonia is an environmentally friendly refrigerant with zero ozone depletion potential (ODP) and negligible global warming potential (GWP), making it compliant with stringent regulations like the EPA’s SNAP Program and EU F-Gas regulations. This eco-friendly profile reduces carbon taxes and environmental liabilities for businesses. Secondly, ammonia offers superior thermodynamic efficiency, with a latent heat of vaporization approximately 8 times higher than R-134a, leading to lower energy consumption—data from industrial case studies show energy savings of 15-25% in refrigeration cycles. Additionally, ammonia heat exchangers are cost-effective due to ammonia’s low cost compared to synthetic refrigerants; for example, ammonia prices are around $1-2 per pound versus $10-20 for some HFCs. Their durability is another key advantage: constructed from materials like carbon steel or stainless steel, they resist corrosion and withstand high pressures (up to 300 psi commonly), resulting in lifespans of 20+ years with minimal maintenance. Safety features, such as leak detection systems and robust designs, mitigate risks, while scalability allows customization for large industrial loads. Real-world data from cold storage facilities indicate that ammonia-based systems reduce operational costs by up to 30% over their lifetime, highlighting their economic and operational benefits.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Plate heat exchanger gaskets perform 5 key roles: ...

More

A gasket in heat exchanger seals surfaces, blocks ...

MoreAPI 662 defines standards for plate heat exchanger...

More

You can see clear differences between welded block...

More

The dimple plate heat exchanger, also known as the...

More

Shanghai Heat Transfer stands out with its ISO9001...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

Michael Thompson

Process EngineerThis ammonia heat exchanger has significantly improved our cooling system's efficiency. The build quality is exceptional and it handles high pressure operations flawlessly. Installation was straightforward with clear documentation.

Sarah Chen

Refrigeration SpecialistReliable performance in our industrial refrigeration application. The heat transfer efficiency meets specifications and maintenance has been minimal. Would recommend for ammonia-based systems.

James Wilson

Plant ManagerOutstanding durability in corrosive environments. We've been running this unit continuously for 8 months with zero performance degradation. The corrosion-resistant materials make it perfect for ammonia applications.

Lisa Rodriguez

HVAC EngineerExcellent thermal performance and energy efficiency. This exchanger has reduced our operating costs by 15% compared to our previous unit. The compact design also saved valuable floor space in our facility.