Best Selling Plate Heat Exchangers for HVAC Applications

Product Name | Latest Month's Sale Volume | Retail Price | Wholesale Price |

|---|---|---|---|

ALECOIL 5"x12" 80 Plates Heat Exchanger | 20 | $236.09 | $69.00 |

Ferroday Wort Chiller, 60 Plate | 10 | $71.57 | $47.74 |

Leading brands such as Alfa Laval, Kelvion, SPX FLOW, and Danfoss are recognized for their reliable performance and innovative designs. The market values high thermal efficiency, compact size, and adaptability. When choosing a plate heat exchanger, consider product features, the brand’s reputation, and the specific needs of your HVAC system.

Plate Heat Exchanger Basics

How Plate Heat Exchangers Work

A plate heat exchanger is a device that transfers heat between two fluids without mixing them. It uses thin metal plates to separate the fluids. The fluids flow in opposite directions, which increases the efficiency of heat transfer. The design allows heat from the hotter fluid to move through the plate wall and reach the cooler fluid. This process is called indirect heat transfer.

The plates have a corrugated pattern. This pattern creates turbulence as the fluids move through the channels. Turbulence helps the fluids exchange heat more quickly. The large surface area of the plates also improves the rate of heat transfer. The counterflow arrangement, where fluids move in opposite directions, maximizes efficiency. The plate heat exchanger is popular in HVAC systems because it can handle high heat transfer rates in a compact space.

Tip: The corrugated plates not only boost heat transfer but also help reduce fouling, which means less maintenance is needed.

Types Used in HVAC

Several types of heat exchangers are used in HVAC systems. Each type has a unique design and set of advantages. The most common types include shell & tube, plate & frame, and dimple plate/plate coil heat exchangers.

Type of Heat Exchanger | Design Description | Key Differences |

|---|---|---|

Shell & Tube Heat Exchangers | Tube pack inside a shell; one fluid in tubes, another in shell. | Robust, cost-effective, less efficient than plate heat exchangers. |

Plate & Frame Heat Exchanger | Series of plates in a frame; alternating spaces for hot and cold fluids. | High efficiency, easy maintenance, modular, flexible capacity. |

Dimple Plate/Plate Coil Heat Exchanger | Two steel sheets spot-welded and inflated to create channels. | Customizable, compact, withstands high pressures, often used in retrofits. |

The plate heat exchanger stands out for its high efficiency and modular design. It is easy to clean and can be expanded by adding more plates. Shell & tube models are sturdy and cost less, but they do not transfer heat as efficiently. Dimple plate designs are compact and customizable, making them suitable for special applications.

Importance of HVAC Plate Heat Exchanger

Energy Efficiency

A plate heat exchanger plays a vital role in improving the performance of HVAC systems. Its design maximizes the heat transfer surface area within a compact footprint. This allows for high efficiency in transferring heat between fluids. In many HVAC applications, the plate heat exchanger helps reclaim heat from exhaust air and uses it to preheat incoming fresh air. This process reduces the heating load and lowers energy consumption.

Experts note that plate and frame heat exchangers have thermal efficiency transfer coefficients three to five times higher than traditional shell-and-tube models. This means HVAC systems can achieve the same heating or cooling effect while using less energy. The ability to reach tight temperature approaches, sometimes as close as 1°C, allows for the use of lower-grade heat sources. This enhances the efficiency of heat pumps and supports energy-efficient solutions in modern buildings.

Some common uses of the hvac plate heat exchanger include:

Separating building HVAC systems from district energy networks.

Maintaining pressure and flow consistency in hydronic systems.

Supporting free cooling applications by using low ambient temperatures to cool water directly.

Note: Efficient heat exchange leads to stable temperature control and reduces unnecessary energy waste.

Space and Cost Savings

The compact design of the plate heat exchanger offers significant advantages in commercial HVAC installations. For the same thermal output, it occupies much less space than shell-and-tube solutions. This makes it ideal for buildings where mechanical room space is limited.

Plate heat exchangers maximize energy transfer, which reduces overall energy consumption.

Their small footprint allows for easy integration into various HVAC applications.

Lower energy losses and reduced operating costs make them a cost-effective choice for climate control.

The modular nature of these units also means that capacity can be adjusted by adding or removing plates. This flexibility helps building owners adapt to changing needs without major system overhauls. As a result, the plate heat exchanger stands out as a smart investment for both new and retrofit projects.

Selection Criteria for HVAC Plate Heat Exchangers

Performance and Efficiency

When evaluating a plate heat exchanger for HVAC applications, several performance metrics help determine the best fit for your system. These metrics provide a clear picture of how well the unit will transfer heat and operate under different conditions:

Heat Transfer Rate (Q): Measures the total heat moved per unit time.

Effectiveness (ε): Compares actual heat transfer to the maximum possible.

Overall Heat Transfer Coefficient (U): Indicates how efficiently heat moves across the plates.

Log Mean Temperature Difference (LMTD): Shows the average temperature difference driving the heat exchange.

Pressure Drop (ΔP): Reflects the resistance to fluid flow through the exchanger.

Capacity Ratio (C*): Compares the heat capacity rates of the two fluids.

NTU (Number of Transfer Units): A dimensionless value for performance.

Fouling Factor (R_f): Accounts for efficiency loss due to buildup on surfaces.

Thermal Efficiency (η): Ratio of heat transferred to cold fluid versus heat removed from hot fluid.

Approach Temperature: The temperature gap between outlet and inlet streams.

Heat Duty: Total heat energy transferred over time.

Selecting a plate heat exchanger with high efficiency and low pressure drop ensures optimal energy use and system performance.

Reliability and Maintenance

Reliability is crucial in HVAC systems. Plate heat exchangers can face challenges such as gasket wear, vibration-induced fatigue, and fouling. Regular maintenance, including cleaning and inspection, helps prevent leaks and efficiency loss. Planned service schedules reduce the risk of unexpected breakdowns. Proper installation and material selection, such as using corrosion-resistant plates, also extend the lifespan of the equipment. Consistent care keeps the plate heat exchanger running smoothly and minimizes downtime.

Certifications and Support

Certifications play a key role in product selection. They verify that a plate heat exchanger meets industry standards for performance and safety. The table below highlights the benefits of certified products:

Benefit | Description |

|---|---|

Verified performance ensures energy savings and lower lifetime operating costs. | |

Ensure reliability and value | Certified units meet power and climate control targets, protecting your investment. |

Promote fair comparisons | Certifications allow for accurate, data-driven product comparisons across brands. |

Support from manufacturers, including technical guidance and after-sales service, further ensures reliable operation and long-term value.

Top HVAC Plate Heat Exchanger Brands

Shanghai Heat Transfer Gasketted Plate Heat Exchanger

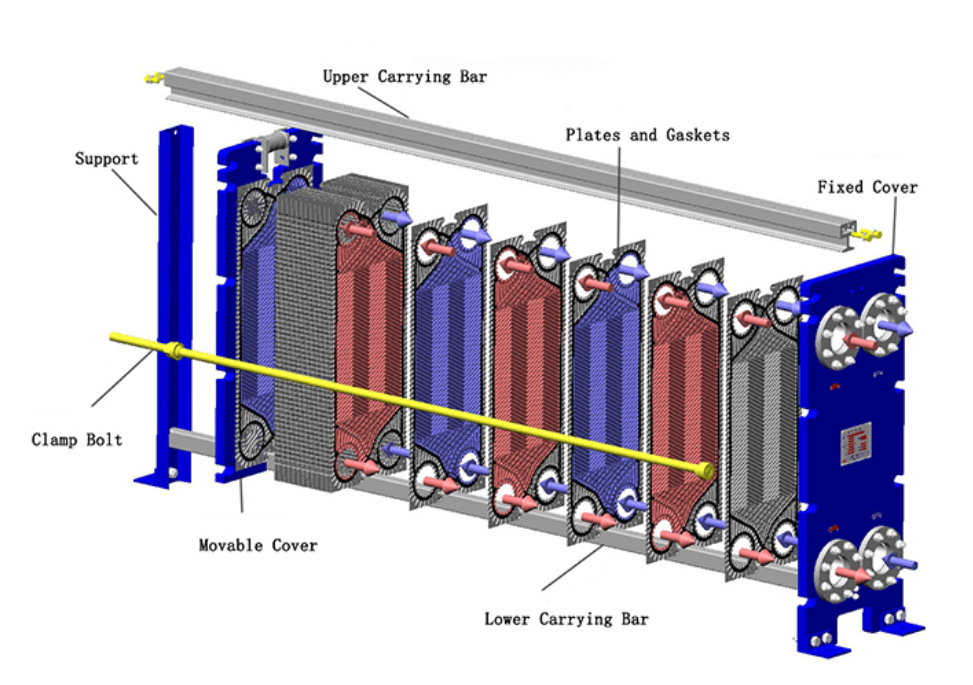

Shanghai Heat Transfer stands out in the HVAC industry with its Gasketted Plate Heat Exchanger. This product combines innovation, efficiency, and adaptability, making it a preferred choice for many HVAC projects. The design uses a series of corrugated plates sealed with gaskets, which allows for easy assembly and disassembly. This feature is important for regular cleaning and maintenance. The modular structure lets users adjust capacity by adding or removing plates, which supports a wide range of heating and cooling needs.

The Gasketted Plate Heat Exchanger offers high surface-area density, which means it can transfer more heat in a smaller space. This compact design saves up to 90% of the space compared to traditional models. The unit operates efficiently even with small temperature differences, making it suitable for energy-saving HVAC systems. The use of advanced materials like stainless steel and titanium ensures durability in demanding environments.

Note: The low fouling design reduces maintenance downtime and keeps performance consistent over time.

Key Features and Advantages:

Feature | Description |

|---|---|

Ensures effective heat transfer, ideal for HVAC applications. | |

Compact Design | Saves space and fits into various installation environments. |

Ease of Maintenance | Gasketed plates allow for quick cleaning and servicing. |

Flexibility in Operation | Capacity can be adjusted to match specific system requirements. |

Low Fouling | Smooth plates and CIP compatibility minimize buildup and downtime. |

Versatile Applications | Used in HVAC, food processing, pharmaceuticals, and more. |

Shanghai Heat Transfer’s plate heat exchanger is popular for its cost-effectiveness, operational flexibility, and reliable performance in both new and retrofit HVAC systems.

Alfa Laval Plate Heat Exchanger

Alfa Laval is a global leader in heat transfer technology. Its plate heat exchangers are known for their high energy efficiency and reliability. The company uses advanced plate patterns that create turbulence, which improves heat transfer and reduces fouling. The rigid plate design prevents elongation and keeps the plates aligned, which helps maintain efficiency over time.

Alfa Laval’s products can achieve approach temperatures as low as 1°F. This capability allows HVAC systems to use lower-grade heat sources and improve overall performance. The plate heat exchanger from Alfa Laval is up to five times more efficient than traditional shell-and-tube models. These features make Alfa Laval a trusted choice for demanding HVAC applications.

SWEP Plate Heat Exchanger

SWEP specializes in compact plate heat exchangers that deliver efficient thermal transfer in limited spaces. These units are maintenance-free and can handle high temperatures and extreme pressures. SWEP’s products use advanced materials and improved flow patterns to boost performance and durability.

SWEP heat exchangers support low-GWP refrigerants, which aligns with modern sustainability goals.

Enhanced corrosion resistance and higher pressure ratings make them suitable for a wide range of HVAC and industrial uses.

The compact structure allows for easy integration into tight mechanical rooms.

SWEP’s focus on innovation and energy efficiency has made it a popular choice for both commercial and industrial HVAC systems.

Kelvion Plate Heat Exchanger

Kelvion is recognized for its durable and efficient plate heat exchangers. The company designs products that perform well in harsh conditions and help reduce operating costs. Kelvion’s technology supports a broad range of applications, from building climate control to industrial processes.

Feature | Kelvion | Other Leading Brands |

|---|---|---|

Durability | Built for harsh conditions | Varies by brand |

Energy Efficiency | Focus on cost reduction | Each brand has unique metrics |

Application Range | Diverse industries | Some specialize in certain sectors |

Kelvion’s plate heat exchangers are valued for their long service life and adaptability. Their strong focus on energy efficiency makes them a reliable option for HVAC projects that require consistent performance.

SPX Flow Plate Heat Exchanger

SPX Flow offers plate heat exchangers that combine compact design with high performance. The modular structure allows for easy expansion, which is useful when system requirements change. SPX Flow uses advanced materials to increase durability, making these units suitable for aggressive fluids and challenging environments.

The compact structure saves space in mechanical rooms.

High heat transfer efficiency supports energy-saving HVAC operations.

Modular design provides flexibility for future upgrades or capacity changes.

SPX Flow’s commitment to innovation and quality has earned it a strong reputation in the HVAC market. Its plate heat exchangers are often chosen for projects that demand both efficiency and adaptability.

Tip: When selecting a hvac plate heat exchanger, consider not only efficiency and size but also the level of after-sales support and warranty offered by the manufacturer.

Plate Heat Exchanger Features

Materials and Design

The choice of materials and design features plays a crucial role in the performance and durability of plate heat exchangers. Manufacturers select materials based on the fluids, temperatures, and pressures involved in HVAC applications. Advanced alloys such as titanium-palladium and Hastelloy C276 offer excellent corrosion resistance, especially in harsh or acidic environments. Nickel 200/201 plates are ideal for high-temperature and caustic solutions. The design of the plates also matters. Herringbone corrugation patterns increase turbulence, which improves heat transfer and reduces fouling. Wide gap channel shapes help prevent blockages when handling viscous fluids.

Material/Design Feature | Description |

|---|---|

Titanium-Palladium Alloy | Excellent corrosion resistance, suitable for high temperature and low pH solutions. |

Hastelloy C276 | Ultra-low carbon nickel alloy, effective in low pH media. |

Nickel 200/201 | Pure nickel plate, ideal for high temperatures and caustic solutions. |

Herringbone Corrugation | Enhances turbulence, reduces fouling, and provides high mechanical strength. |

Wide Gap Channel Shape | Prevents blockage and reduces pressure drop for high viscosity fluids. |

Low Fouling and Maintenance

Low fouling characteristics are essential for efficient operation and long service life. Plate heat exchangers with smooth surfaces and optimized flow patterns require less frequent cleaning. This reduces downtime and labor costs. Over time, these features can lower lifetime service costs by up to 30%. Regular maintenance, such as inspections and cleaning, helps identify potential issues early and extends the lifespan of the equipment.

Tip: Diligent maintenance practices and proactive issue resolution enhance reliability and keep operational efficiency high.

Factor | Impact on Lifespan |

|---|---|

Low Fouling | Maintains heat transfer efficiency and minimizes energy consumption. |

Effective Maintenance | Identifies and mitigates issues, extending the lifespan of heat exchangers. |

Scalability and Modularity

Scalability and modularity are key advantages of modern plate heat exchangers. Modular mounting systems allow for easy installation and customization. Users can assemble or disassemble units onsite, which saves time and space. The flexibility in configurations means that systems can adapt to different sizes and requirements. Capacity adjustments are simple—adding or removing plates can increase or decrease performance as needed. This supports scalable systems and phased project rollouts.

Feature | Description |

|---|---|

Modular Mounting Systems | Enable easy installation, maintenance, and customization. |

Flexibility in Configurations | Allow assembly in various sizes and types for different needs. |

Simplified Component Changes | Make it easy to add or replace components, enhancing scalability. |

Plate heat exchangers are lighter and occupy less floor space than traditional units, making them ideal for both new and retrofit HVAC projects.

How to Choose the Right Plate Heat Exchanger

Assessing HVAC Needs

Selecting the right plate heat exchanger starts with a clear understanding of your HVAC system’s requirements. Begin by identifying the heating or cooling load. Consider the type of fluids involved and their temperatures. Check the available space for installation. Note the operating pressure and temperature ranges. Each of these factors will influence the size and type of heat exchanger needed. For example, a compact unit may be necessary for a mechanical room with limited space. Systems that handle aggressive fluids may require specialized materials for durability.

Tip: Always match the heat exchanger’s capacity to your system’s peak demand to ensure reliable performance year-round.

Comparing Product Specs

Comparing technical specifications helps you find the best fit for your application. Focus on features that impact efficiency, durability, and ease of maintenance. The following tables highlight key aspects to consider:

Specification Type | Description |

|---|---|

Optimized Plate Geometries | Increases turbulence and heat transfer surface area for better efficiency. |

Improved Flow Distribution | Ensures even fluid flow, reducing pressure drop and maximizing heat transfer. |

Specialized Corrugation Patterns | Boosts turbulence and heat transfer coefficients for superior thermal exchange. |

Material Aspect | Impact |

|---|---|

Thermal Conductivity | Advanced materials improve performance and extend service life. |

Corrosion Resistance | Enhances durability and maintains efficiency in harsh environments. |

Surface Treatments | Lowers fouling and scaling, keeping the unit efficient over time. |

Efficiency Technique | Benefit |

|---|---|

Advanced Header Designs | Promotes uniform fluid distribution, preventing hot or cold spots. |

Computational Fluid Dynamics | Optimizes flow paths, eliminating dead zones and improving heat transfer. |

Note: Plate heat exchangers offer a high heat transfer coefficient, compact size, and easy maintenance compared to shell and tube models.

Expert Consultation

Consulting with industry experts can simplify the selection process. Specialists provide guidance tailored to your specific application. They help you choose the most suitable plate heat exchanger, ensuring optimal performance and efficiency. Experts can also recommend the best materials and designs for your system, maximizing heat transfer and reliability.

Choosing the right hvac plate heat exchanger is vital for system performance. Leading brands offer unique strengths, as shown below:

Manufacturer | Key Features |

|---|---|

Aidear | Innovative, sustainable designs |

GEA Group | Industrial expertise, customer-focused solutions |

API Heat Transfer | Custom options, advanced manufacturing |

Swep International | Compact, energy-efficient, global reach |

Kelvion | Durable, efficient, versatile |

When selecting a hvac plate heat exchanger, consider thermal efficiency, reliability, and support. Trusted brands like Shanghai Heat Transfer provide tailored solutions. Stay informed about new trends, such as modular designs and sustainable materials, to keep your system efficient.

FAQ

What is a plate heat exchanger used for in HVAC systems?

A plate heat exchanger transfers heat between two fluids. HVAC systems use it to recover energy, separate circuits, and improve efficiency. It helps maintain comfortable indoor temperatures while saving energy.

How do I maintain a plate heat exchanger?

Regular cleaning and inspection keep the unit efficient. Remove plates for cleaning if fouling occurs. Check gaskets for wear. Many models support Clean-in-Place (CIP) systems, which simplify maintenance.

Can I expand the capacity of my plate heat exchanger?

Yes. Many plate heat exchangers have a modular design. You can add or remove plates to adjust capacity. This flexibility supports system upgrades or changes in building demand.

What materials are best for plate heat exchangers in HVAC?

Stainless steel is common for most HVAC applications. Titanium and Hastelloy work well in corrosive environments. The right material depends on the fluids, temperature, and pressure in your system.