Comparing welded block and gasketed plate heat exchangers

You can see clear differences between welded block...

More

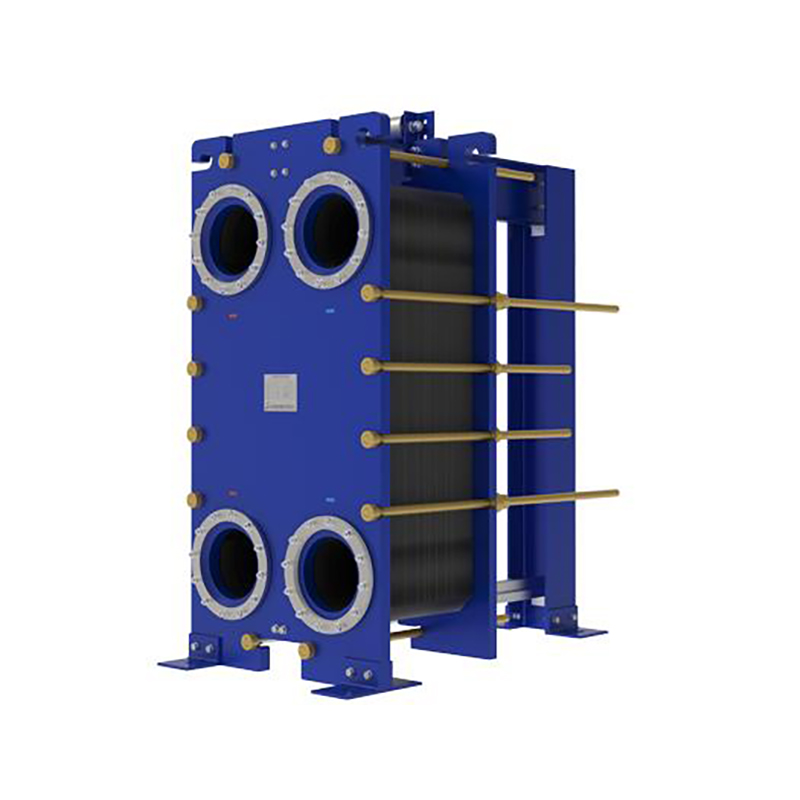

A block type heat exchanger is a compact and robust thermal transfer device designed for efficient heat exchange between two fluids. It consists of a solid metal block with intricately machined channels that allow fluids to flow in close proximity without mixing, facilitating rapid heat transfer. These exchangers are widely used in industries such as chemical processing, power generation, and HVAC due to their durability, high thermal conductivity, and space-saving design. Unlike traditional shell-and-tube models, block type exchangers minimize energy loss and are ideal for high-pressure and high-temperature applications. Their modular construction also simplifies maintenance and scalability.

Block type heat exchangers excel in performance by leveraging advanced materials like stainless steel, titanium, or aluminum to withstand corrosive environments and extreme conditions. Their design ensures minimal pressure drop, reducing operational costs while maximizing heat recovery. Industries favor them for applications like gas cooling, lubricant temperature control, and waste heat recovery. For example, in the oil and gas sector, they improve efficiency by preheating crude oil using residual heat from other processes. Their adaptability to custom configurations—such as multi-pass flow arrangements—makes them versatile for diverse operational needs.

Opting for a block type heat exchanger offers unparalleled advantages in energy efficiency, reliability, and cost-effectiveness. These systems outperform conventional heat exchangers by delivering superior thermal transfer rates with minimal maintenance requirements. Their compact footprint reduces installation space by up to 50% compared to shell-and-tube units, as evidenced by industry case studies. Additionally, their leak-proof design eliminates cross-contamination risks, critical for sensitive processes in pharmaceuticals and food processing.

Data from market research highlights that block type heat exchangers can achieve thermal efficiencies exceeding 90%, significantly lowering energy consumption. For instance, a European chemical plant reported a 30% reduction in cooling costs after switching to block type models. Their scalability allows seamless integration into existing systems, while corrosion-resistant materials extend service life beyond 20 years. With certifications like ASME and PED compliance, these exchangers meet stringent safety standards. Industries prioritizing sustainability benefit from their ability to recover up to 80% of waste heat, aligning with global carbon reduction goals. Whether for heavy industry or precision applications, block type heat exchangers deliver unmatched ROI and operational excellence.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

You can see clear differences between welded block...

More

Plate heat exchanger gaskets perform 5 key roles: ...

More

A gasket in heat exchanger seals surfaces, blocks ...

More

API 662 defines standards for plate heat exchanger...

More

Compare top frame plate heat exchanger models for ...

More

Plate heat exchangers are becoming more popular be...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

John Smith

Mechanical EngineerThe block type heat exchanger is incredibly efficient and easy to install. It has significantly improved our system's performance.

Emily Johnson

HVAC TechnicianGreat product! The block type heat exchanger works perfectly for our commercial HVAC systems. Highly recommend for energy efficiency.

Michael Brown

Process EngineerThis heat exchanger has exceeded our expectations. The build quality is excellent, and it handles high temperatures with ease.

Sarah Davis

Plant ManagerThe block type heat exchanger has been a reliable addition to our facility. It's durable and requires minimal maintenance.