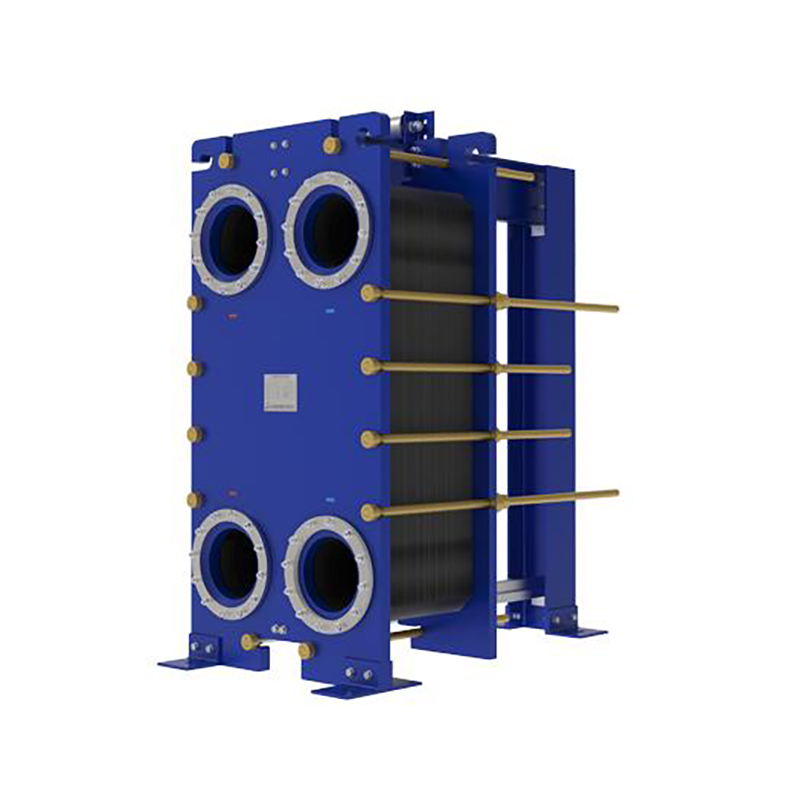

Carbon Block Heat Exchangers as a Solution for Aggressive Chemicals

A carbon block heat exchanger provides a premier solution for managing aggressive chemicals.

Its material shows exceptional corrosion resistance and high thermal conductivity. These unique properties make the equipment ideal for harsh environments, including hydrochloric acid and sulfuric acid processing, where other materials often fail.

Why Carbon Block Excels in Corrosive Environments

A carbon block heat exchanger thrives in harsh chemical environments due to two primary material advantages. Its chemical inertness provides unparalleled protection against corrosion. Its graphite base offers excellent heat transfer capabilities. These factors combine to create a highly effective and reliable solution.

Unmatched Corrosion Resistance

Graphite is a naturally inert material. It does not react with most aggressive chemicals. This property gives it a significant advantage over metal alloys, which often corrode, pit, or fail completely when exposed to certain substances. Many industrial processes involve chemicals that are highly destructive to standard equipment.

Common culprits that degrade metal surfaces include:

Acids

Chlorinated compounds

Vaporized fluids

Note: The presence of ions like chlorides and sulfates, along with extreme pH levels, accelerates the breakdown of metals. Carbon's inherent resistance to these factors makes it a default material choice for processes involving hydrochloric acid, sulfuric acid, and other challenging media.

Superior Thermal Performance

Effective corrosion resistance is only useful if the equipment can also transfer heat efficiently. Graphite, the primary component of carbon blocks, possesses outstanding thermal conductivity. This property often surpasses that of many corrosion-resistant metals, allowing for rapid and efficient temperature control.

Manufacturers enhance graphite's natural properties through impregnation. This process involves filling the graphite's pores with advanced resins. For example, some designs use a graphite substrate impregnated with a proprietary phenolic resin. This treatment boosts the material's strength and allows it to handle high temperatures without degrading. The specific type of impregnation determines the exchanger's operational limits.

Different graphite grades offer performance tailored to specific applications.

| Graphite Grade | Impregnation Type | Maximum Temperature |

|---|---|---|

| BS (extruded) | Phenolic resin | 220°C (428°F) |

| XBS (isostatic) | Phenolic resin | 220°C (428°F) |

| XTH (isostatic) | PTFE resin | 250°C (482°F) |

| XC (isostatic) | Carbon resin | 430°C (806°F) |

This combination of high thermal conductivity and impressive temperature resistance makes the carbon block heat exchanger a powerful and efficient tool for the most demanding thermal management tasks.

Understanding the Limitations of a Carbon Block Heat Exchanger

While a carbon block heat exchanger offers excellent performance, operators must understand its inherent limitations to ensure safe and efficient operation. The material's primary drawbacks relate to its physical properties and the complexities of maintenance. Acknowledging these challenges is the first step toward implementing modern solutions that mitigate them.

Material Aging and Brittleness

Graphite is a ceramic material. This gives it fantastic chemical resistance but also makes it inherently brittle. Unlike metals that can bend or deform under stress, graphite can fracture. This brittleness becomes a more significant concern as the material ages. The phenolic resins used to impregnate the graphite degrade over time due to thermal cycling and continuous operational stress.

This aging process reduces the material's strength and makes it more susceptible to damage. A properly operated unit can have a service life exceeding 15-20 years. However, an operational life of less than eight years often indicates that alternative materials or designs should be considered. The most common failure is tube breakage, which results from a combination of resin aging and fatigue loading from operational vibrations.

Maintenance and Repair Challenges

The brittle nature of graphite complicates maintenance and repair procedures. Traditional repair methods are often difficult, time-consuming, and require specialized expertise.

Repairing a damaged tube in a conventional cemented-tube design is a major undertaking. It often involves shipping the entire unit back to the manufacturer, leading to extended downtime and significant production losses. 🚧

Regular inspections are critical for identifying potential issues before they lead to catastrophic failure. Maintenance teams should look for specific signs of material degradation.

| Common Issue | Description |

|---|---|

| Fouling and Scaling | Buildup of materials on tube surfaces reduces thermal efficiency and can obstruct flow. |

| Tube Leaks and Cracks | Caused by fatigue or thermal shock, these defects can lead to fluid cross-contamination. |

| Erosion | Mechanical wear thins tube walls, especially in areas with high fluid turbulence. |

| Mechanical Damage | Physical impacts can cause dents or distortions, leading to seal failure or poor fluid distribution. |

Beyond visual inspections, operators should also be alert to sensory clues that may indicate a problem. These signs can signal a compromised heat exchanger that requires immediate attention.

Unusual Noises: Rattling or popping sounds can point to cracks or stress from thermal expansion.

Strange Odors: Unpleasant smells, such as formaldehyde, may indicate resin degradation.

Visible Corrosion: Discoloration or pitting on connected metal components can signal a leak.

Performance Drop: Longer heating cycles or an inability to reach target temperatures suggest reduced efficiency, possibly from fouling or internal leaks.

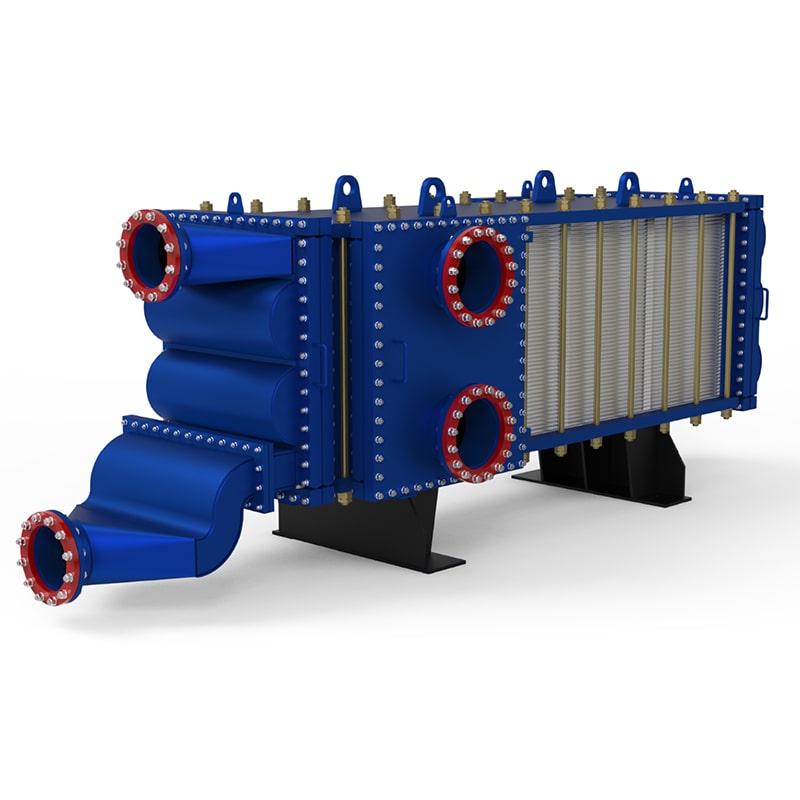

Innovations in Modern Heat Exchanger Design

Engineers have developed new designs to overcome the traditional limitations of carbon block heat exchangers. These advancements focus on improving reliability, simplifying maintenance, and extending the equipment's service life. Recent innovations in flow patterns and control systems can improve energy efficiency by 15-30% compared to older designs, leading to significant operational cost savings.

Advanced O-Ring Sealing Technology

Modern designs replace cemented tubes with an advanced O-ring sealing system. This technology is a major improvement for preventing leaks and simplifying repairs. In these systems, each graphite tube is sealed individually with a high-performance O-ring.

The O-ring's elasticity maintains a robust, leak-proof seal even with slight movements from vibration or temperature changes. This is a significant advantage over rigid, traditional seals that can fail under operational stress.

The choice of O-ring material is critical for ensuring chemical compatibility and long-term performance. For highly corrosive applications, manufacturers use specialized materials.

These materials ensure the seal maintains its integrity, preventing leaks and costly downtime.

Simplified On-Site Tube Replacement

The move to O-ring seals makes maintenance far more manageable. Since tubes are not permanently cemented into the block, a damaged tube can be replaced individually. This innovation transforms a major repair into a routine maintenance task.

Technicians can perform the replacement directly on-site, a process that generally takes from several hours to a few days. This eliminates the need to ship the entire unit back to the manufacturer. The benefits of this simplified process are substantial, delivering a rapid return on investment. Case studies show that modern designs can lead to a 6x increase in mean time between tube leaks and provide over $2 million in annual savings from reduced maintenance and avoided production losses.

High-Performance Material Alternatives

While modern graphite designs offer significant improvements, some applications demand even greater performance. Engineers have developed alternative tube materials that can be integrated into carbon block heat exchangers. These materials provide specialized properties for the most extreme process conditions.

Silicon Carbide (SiC) for Universal Resistance

Silicon carbide (SiC) represents a premium upgrade for heat exchanger tubes. It offers nearly universal chemical resistance and outstanding mechanical strength. SiC is one of the hardest materials available, surpassed only by diamond and boron carbide. This extreme hardness provides excellent resistance to erosion and wear.

A key advantage of SiC is its ability to withstand chemicals that attack other materials. It is the only ceramic that is not corroded by hydrofluoric acid, a notoriously aggressive substance.

While SiC tubes are more expensive than graphite, their superior durability can justify the cost in demanding applications. Their exceptional thermal shock resistance allows them to handle rapid temperature changes without fracturing.

| Corrosive Medium | Temperature | Corrosion Rate (mm/Y) |

|---|---|---|

| 54% Hydrofluoric Acid | 25°C (77°F) | 0.0002 |

| 10% HF & Nitric Acid | 120°C (248°F) | 0.0040 |

This combination of properties makes SiC an ideal choice for processes where reliability is paramount. Other high-performance metals like Titanium and Hastelloy also offer excellent corrosion resistance but may not match SiC's performance across such a wide chemical spectrum.

PPS-GR Composites for Enhanced Ductility

PPS-GR is an innovative composite material that addresses the primary weakness of graphite: brittleness. This material combines polyphenylene sulfide (PPS) with special graphite (GR). The resulting composite tube retains good thermal performance and chemical resistance while gaining significant ductility.

The PPS polymer matrix makes the tubes less fragile and more resistant to mechanical shock and vibration. This enhanced toughness reduces the risk of tube breakage during operation or maintenance. PPS-GR tubes can operate continuously at temperatures up to 220°C (425°F), making them suitable for many chemical processing applications. This material provides a robust and reliable alternative for environments where the risk of mechanical damage is a concern.

Traditional carbon block heat exchanger designs face limits from material aging and difficult maintenance. Modern innovations like O-ring seals and advanced materials boost reliability and simplify repairs. These advancements align with industry trends toward high-efficiency equipment, making the carbon block heat exchanger a more robust and cost-effective solution for demanding applications.

FAQ

What is the main benefit of a carbon block heat exchanger?

Its graphite material offers excellent corrosion resistance against aggressive chemicals. This property makes it ideal for harsh industrial processes where metals often fail.

Are there any downsides to using graphite?

Yes, graphite is brittle and can fracture under stress. The material also ages over time, which can reduce its strength and lead to maintenance challenges.

How do modern designs improve reliability?

New designs use O-ring seals instead of cement. This technology simplifies tube replacement and creates a more durable, leak-proof seal for better operational performance.