Gasketed Plate Heat Exchangers Transforming Industrial Efficiency

Gasketed plate heat exchangers boost industrial ef...

More

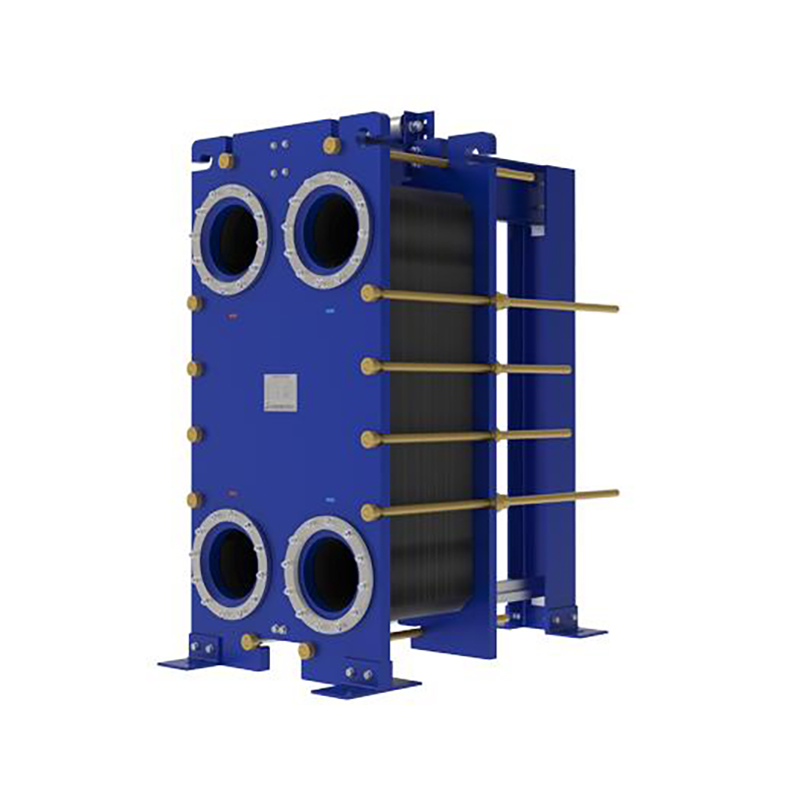

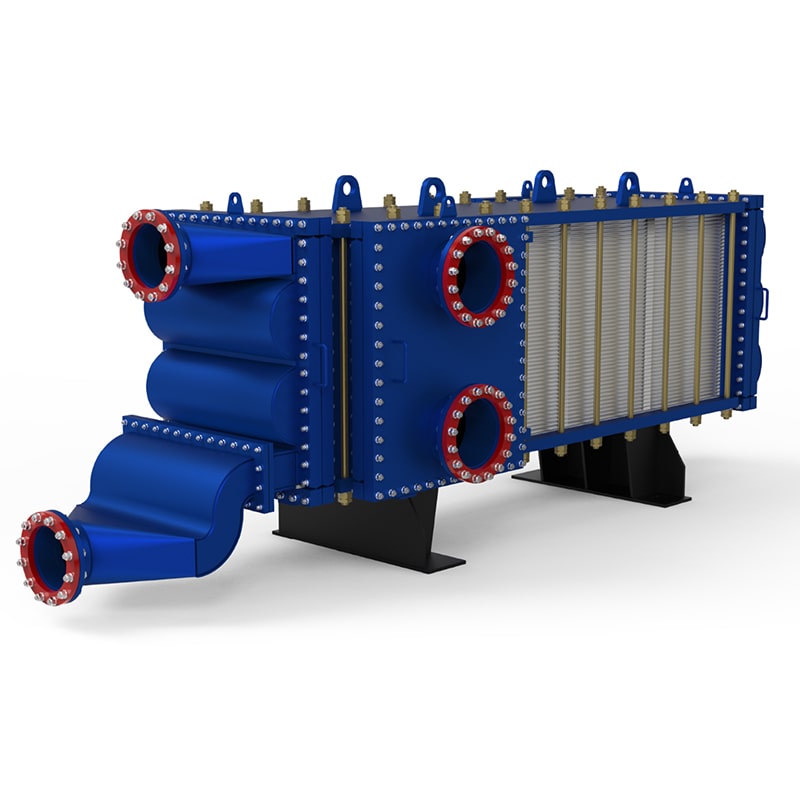

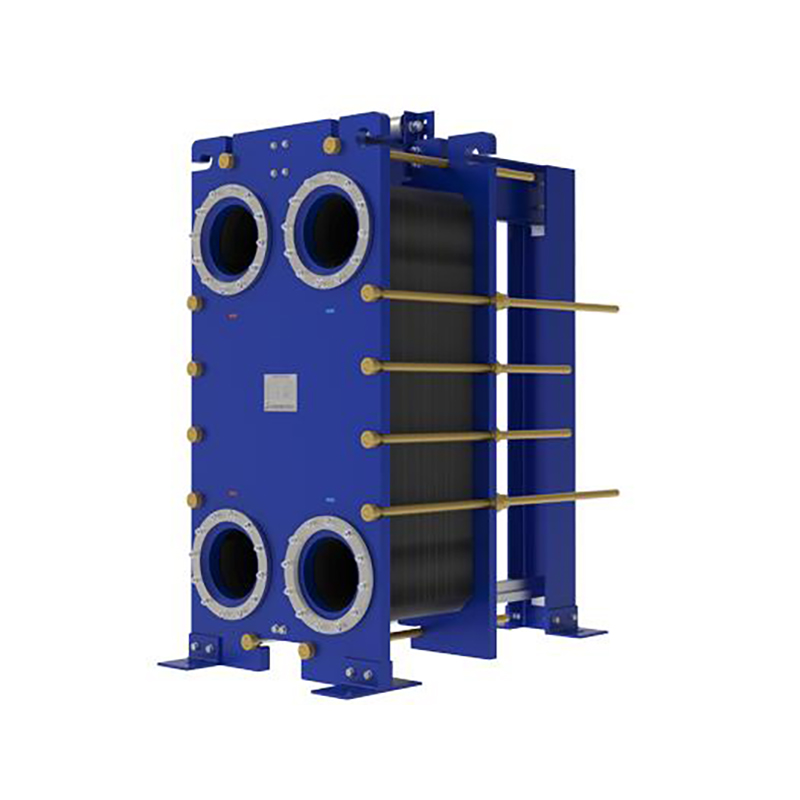

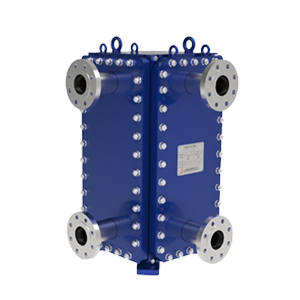

The principle of a Chiller Plate Heat Exchanger (PHE) revolves around efficient thermal energy transfer between two fluid streams—typically a process fluid requiring cooling and a refrigerant or chilled water circuit—without allowing them to mix. This is achieved through a compact assembly of corrugated metal plates, usually made from stainless steel or titanium for corrosion resistance, which are gasketed, brazed, or welded together to form channels. The plate design creates a large surface area relative to the unit’s footprint, promoting turbulent flow even at lower fluid velocities. This turbulence minimizes laminar boundary layers, significantly enhancing heat transfer coefficients compared to traditional shell-and-tube exchangers. In vapor compression or absorption chiller systems, the PHE acts as the evaporator or condenser where phase change occurs, leveraging the high thermal conductivity of the plates and the optimized flow paths to maximize efficiency. The logarithmic mean temperature difference (LMTD) is minimized due to the counter-current or cross-current flow arrangements, ensuring接近 approach temperatures and reducing the energy required for compression or pumping. Advanced designs incorporate asymmetrical plate patterns to handle differing fluid properties and pressures, while computational fluid dynamics (CFD) optimizes channel geometry for specific applications such as high-glide refrigerant mixtures or variable loads. The modularity allows for easy capacity adjustment by adding or removing plates, making it adaptable to precise thermal duties in HVAC, industrial process cooling, and data center cooling systems.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Gasketed plate heat exchangers boost industrial ef...

More

Printed circuit heat exchanger advancements in 202...

More

Leakage free air preheater solutions from top bran...

More

A standard exchange heat exchanger boosts industri...

More

Plate heat exchangers boost industrial energy effi...

More

Solve leakage, fouling, corrosion, blockages, and ...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

Michael Rodriguez

Facility ManagerThe CHILLER PHE has been a game-changer for our data center cooling. Its efficiency and reliability have significantly reduced our energy costs. The compact design was perfect for our space constraints.

Sarah Chen

Chief EngineerOutstanding performance and durability. We've integrated this plate heat exchanger into our industrial process chiller system, and it has handled the high demands flawlessly with minimal maintenance required.

David Kim

HVAC Project ManagerA highly efficient and robust plate heat exchanger for commercial chiller applications. The installation was straightforward, and it has improved our system's overall heat transfer coefficient noticeably. Very satisfied.

Emily Watson

Plant Operations DirectorThis PHE unit for our central chilling plant has exceeded all expectations. The thermal efficiency is remarkable, leading to substantial operational savings. A critical and reliable component in our cooling infrastructure.