Leakage free air preheater picks that stop waste now

Leakage free air preheater solutions from top bran...

More

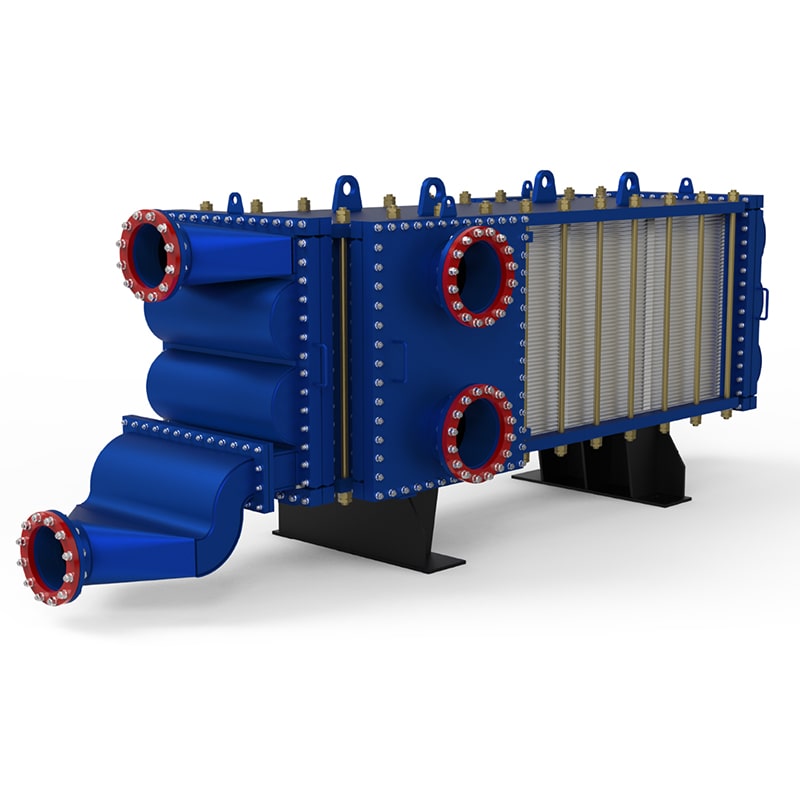

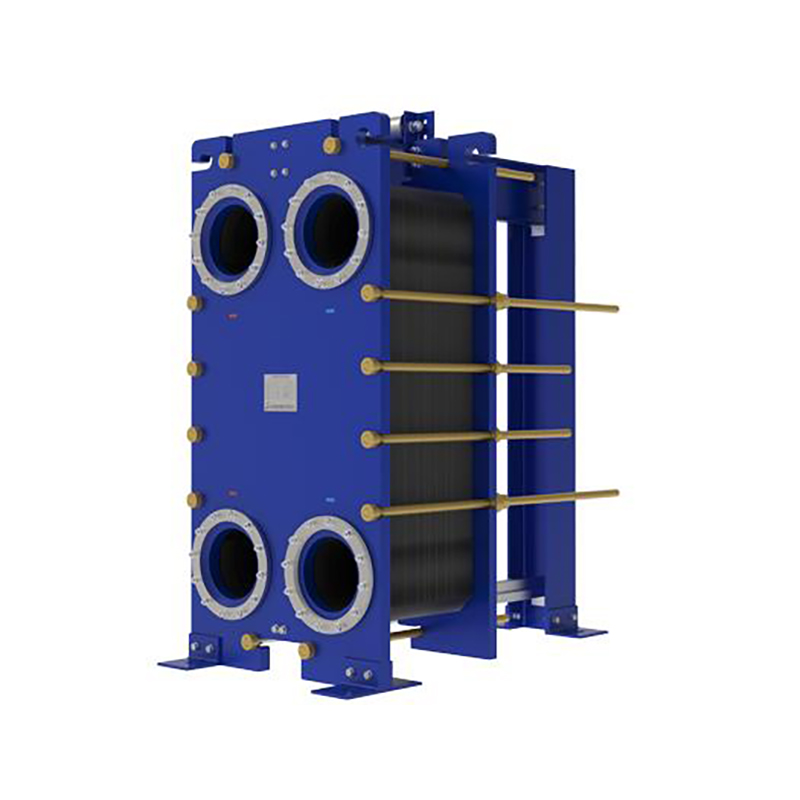

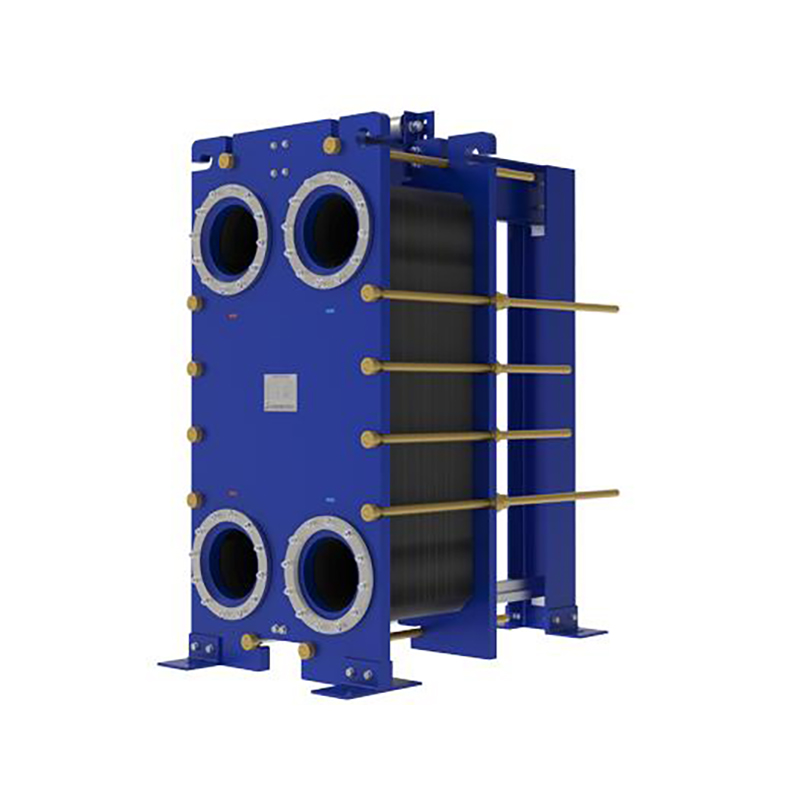

A combustion air preheater (CAPH) is an essential energy recovery heat exchanger positioned within the flue gas stream of an industrial combustion process. Its primary function is to capture waste heat from the hot exhaust gases exiting a boiler, furnace, oven, or kiln and transfer it to the incoming combustion air. This process significantly raises the temperature of the air supplied for burning fuel before it enters the combustion chamber. By preheating the combustion air using energy that would otherwise be lost to the atmosphere, the system directly reduces the amount of fuel required to achieve the desired operating temperature, leading to substantial gains in overall thermal efficiency and notable reductions in fuel consumption and associated greenhouse gas emissions. These systems are critical components in a wide array of industries, including power generation, petroleum refining, chemical processing, pulp and paper production, and metal manufacturing, where they are integral to modern energy conservation and emissions control strategies.

The operational principle is based on fundamental thermodynamics. The specific design can vary, with the two most common types being recuperative and regenerative. Recuperative preheaters function by having the cold combustion air and hot flue gas streams flow on opposite sides of a solid heat transfer surface, such as plates or tubes, allowing heat to conduct from the gas to the air without the streams mixing. In contrast, regenerative preheaters, often called regenerators or Ljungström-type heaters, use a rotating matrix (heat wheel) that alternately passes through the hot flue gas stream to absorb heat and then through the cold air stream to release it. The choice between systems depends on factors like required efficiency, temperature levels, pressure drop constraints, and the potential for fouling from the flue gas. Their implementation is a cornerstone of industrial energy management, directly impacting the bottom line and environmental footprint.

The advantages of integrating a combustion air preheater into an industrial system are profound and multi-faceted, impacting economics, operational performance, and environmental compliance. The most significant benefit is drastically improved fuel efficiency. By recycling waste heat back into the process, the preheater reduces the fuel energy needed to raise the combustion air to the optimal temperature. Industry data and case studies consistently show that for every 20°C (36°F) rise in combustion air temperature, boiler efficiency increases by approximately 1%. This can translate to fuel savings of 5% to 10% or more, a substantial reduction in operational expenses for energy-intensive industries. Furthermore, higher combustion air temperatures promote more stable and complete combustion of the fuel. This results in lower emissions of unburned hydrocarbons (UHC), carbon monoxide (CO), and particulate matter, aiding facilities in meeting stringent environmental regulations.

Additional advantages include increased production capacity. For a fixed fuel input rate, the net energy available for the process increases due to reduced stack losses, potentially allowing for higher throughput. The elevated air temperature also ensures better flame stability and allows for the effective use of lower-grade or harder-to-burn fuels. Moreover, by lowering the flue gas temperature entering downstream equipment like particulate scrubbers or baghouses, preheaters can reduce the thermal load on these components and minimize the volume of gas that needs to be treated, potentially lowering the capital and operating costs of pollution control systems. The return on investment (ROI) for a combustion air preheater is often remarkably short, frequently cited at between 6 months to 2 years, making it one of the most financially attractive energy conservation measures available for combustion systems.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Leakage free air preheater solutions from top bran...

More

Compare top steam heat exchanger suppliers and pro...

More.jpg)

Plate air preheaters transform industrial processe...

More

Selecting the right preheater air system shapes th...

More

Factories in 2025 rely on advanced gasketed heat e...

More

A heater exchanger lowers energy bills by efficien...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

Michael Chen

Lead Process EngineerThis combustion air preheater has been a game-changer for our plant's efficiency. The heat recovery is exceptional, significantly reducing our fuel consumption. Installation was straightforward, and it has required zero maintenance in the first year of operation. A robust and brilliantly engineered product.

Sarah Johnson

Plant ManagerWe installed this preheater on our boiler system and the ROI was faster than projected. The build quality is superior, and it handles the daily thermal cycles without any issues. It's a critical component for our sustainability goals, drastically cutting our energy costs and carbon footprint.

David Rodriguez

Maintenance SupervisorExtremely durable and effective unit. The air preheater performs exactly as advertised, providing a consistent and high-temperature air supply to our furnaces. The only reason it's not a 5 is that the initial setup documentation could be slightly more detailed. Otherwise, highly reliable.

Emily Williams

Project EngineerOutstanding performance and integration. This preheater was a key part of our system upgrade, and the technical support from the vendor was top-notch during the design phase. It's incredibly efficient and has eliminated the cold-end corrosion problems we had with our previous model.