Commercial Heat Exchangers A Deep Dive into Energy Savings

The Principle of Heat Recovery and Energy Reduction

The core function of commercial heat exchangers is rooted in the principles of thermodynamics. These laws explain how energy moves and transforms, providing the foundation for heat recovery.

-

First Law of Thermodynamics: Energy cannot be created or destroyed. Heat simply moves from a hotter fluid to a cooler one without any loss of total energy.

-

Second Law of Thermodynamics: Heat naturally flows from a hot source to a cooler one. A heat exchanger facilitates this natural process efficiently.

Capturing and Reusing Waste Heat

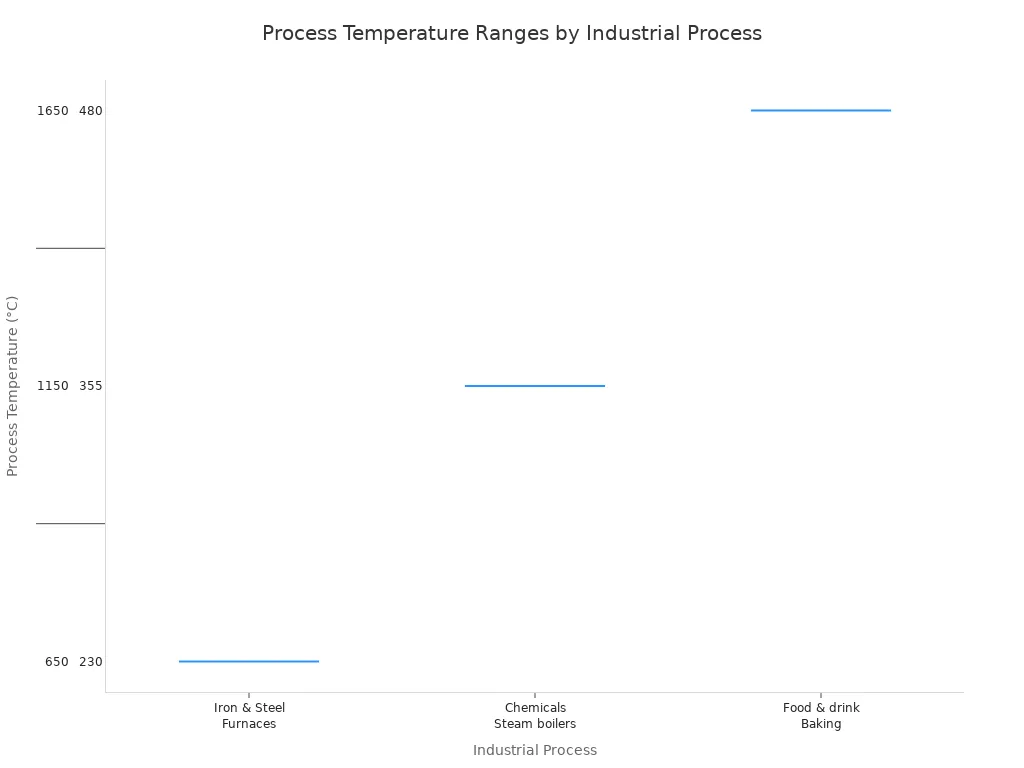

Many industries generate enormous amounts of thermal energy that is often vented into the atmosphere as waste. This represents a significant untapped resource. Heat exchangers capture this energy for reuse, directly lowering the demand on primary heating systems. Key industries producing recoverable waste heat include:

·Iron & Steel

·Chemicals and Petrochemicals

·Cement and Glass Manufacturing

·Pulp and Paper

·Food and Beverage

Quantifying Your Energy Savings

Calculating the potential savings is a straightforward process. It helps facilities understand the financial benefit of installing a heat recovery system.

Note: The Energy Savings FormulaAnnual energy savings can be estimated using the formula:Esavings = Qrecoverable × Hoursannual × (1/ηdisplaced)Here, Qrecoverable is the recoverable heat, Hoursannual is the yearly operating time, and ηdisplaced is the efficiency of the system being offset.

These calculations translate into substantial real-world benefits. For example, one cereal manufacturer saved $500,000 annually, while a hospital reduced its boiler gas consumption by 30%. The return on investment is often rapid. Some projects, like one involving a cooker's wastewater stream, have achieved a full payback period in less than 90 days.

Types of Commercial Heat Exchangers and Their Impact

Selecting the right heat exchanger is crucial for maximizing energy savings. The ideal choice depends on the specific application, including the fluids involved, temperature ranges, and pressure requirements. Different types of commercial heat exchangers offer distinct advantages for various operational needs.

Note: The design of a heat exchanger directly influences its efficiency, maintenance demands, and overall return on investment. Understanding the primary types is the first step toward an effective heat recovery strategy.

Shell and Tube for Robust Applications

Shell and tube heat exchangers are the workhorses of many industries. Their design is straightforward yet powerful. A large cylindrical shell encloses a bundle of tubes. One fluid flows through the tubes while another fluid flows over the tubes within the shell. This configuration facilitates heat transfer between the two.

These units are known for their durability. They can withstand very high pressures and extreme temperatures. This robustness makes them essential in demanding environments. Their applications span a wide range of heavy industries.

·Oil and Gas: Used for crude oil cooling, gas compression, and processing in refineries.

·Power Generation: Employed in condensers to turn steam back into water.

·Chemical Manufacturing: Critical for process heating, cooling, and condensing various chemicals.

·Food and Beverage: Applied for processes like pasteurization and sterilization that require high durability.

·Automotive and Aerospace: Utilized in engine cooling and hydraulic systems.

·Pulp and Paper: Employed for pulp digestion and drying processes.

Plate and Frame for High-Efficiency Transfer

Plate and frame heat exchangers offer a modern, highly efficient alternative. These units consist of a series of thin, corrugated metal plates bolted together in a frame. The design creates narrow channels for fluids to flow through. This large surface area allows for exceptionally rapid and efficient heat transfer.

Compared to traditional shell and tube models, plate and frame exchangers provide superior performance in a much smaller package. Their modular design also offers significant advantages in maintenance and scalability.

| Feature | Plate and Frame Exchanger | Shell and Tube Exchanger |

|---|---|---|

| Efficiency | Transfers heat up to five times more efficiently. | Lower heat transfer coefficient. |

| Footprint | Requires as little as one-tenth the floor space. | Much larger and heavier. |

| Maintenance | Plates are easily accessible for cleaning and inspection. | Tube bundles are difficult to pull and clean. |

| Flexibility | Capacity can be easily adjusted by adding or removing plates. | Capacity is fixed upon installation. |

| Fouling | High turbulence in channels reduces deposit buildup. | More susceptible to scaling and fouling. |

The food and beverage industry frequently relies on plate and frame exchangers for precise temperature control. Their efficiency is vital for product quality and safety.

·Pasteurization: Quickly heats and cools products like milk, juice, and sauces to extend shelf life.

·Cooling and Heating: Provides exact temperature control for chilling dairy or heating soups.

·Energy Recovery: Reuses waste heat from cooking to preheat raw materials, lowering energy bills.

·Washing and Sterilization: Heats cleaning fluids to maintain strict hygiene standards.

Air-to-Air for HVAC Systems

Air-to-air heat exchangers are fundamental to energy-efficient HVAC (Heating, Ventilation, and Air Conditioning) systems. These devices work by transferring thermal energy from a stale exhaust air stream to the incoming fresh air stream. This process pre-heats the fresh air in winter and pre-cools it in summer. The result is a significant reduction in the energy needed to condition the building's air, with potential savings of up to 30%.

These systems, often called Energy Recovery Ventilators (ERVs), improve indoor air quality while lowering operational costs. There are two primary types of air-to-air exchangers:

·Fixed Plate Exchangers: These units have no moving parts. They use alternating layers of plates to keep the air streams separate while allowing heat to transfer through the material. They primarily transfer sensible heat (temperature) and are known for their reliability.

·Rotary Wheel Exchangers: Also known as enthalpy wheels, these feature a rotating cylinder filled with an air-permeable material. As the wheel turns, it absorbs heat and moisture from one air stream and releases it into the other. This allows them to transfer both sensible heat and latent heat (humidity), making them highly effective in managing indoor comfort.

Key Factors for Maximizing Efficiency

Selecting the right type of heat exchanger is only the first step. To truly unlock maximum energy savings and ensure a long operational life, facility managers must focus on two critical factors: proper sizing and strategic material selection. These decisions directly influence both upfront costs and long-term performance.

The Importance of Proper Sizing

Correctly sizing a heat exchanger is a balancing act between performance needs and physical constraints. It is arguably the most important decision in the design phase. An improperly sized unit will either fail to meet demand or operate inefficiently, negating potential energy savings.

An undersized unit creates immediate and persistent problems. It consistently fails to achieve the target temperatures required by the process. This forces the entire system to work harder and run longer, leading to several negative outcomes:

·Higher energy bills from constant operation.

·Increased wear and tear on components, causing more frequent breakdowns.

·Inconsistent heating or cooling, which can affect product quality or occupant comfort.

·A risk of excessive condensation, which can corrode internal components and create safety hazards like carbon monoxide.

Conversely, oversizing a unit presents its own set of challenges. While some may oversize a unit to account for future fouling, this strategy has significant drawbacks. An oversized heat exchanger is larger and carries a higher initial purchase price. More importantly, it can operate inefficiently, especially at lower loads. For example, a 20% oversized steam-fed unit can experience a severe drop in steam pressure during minimum load conditions. This pressure drop can prevent steam traps from discharging condensate effectively, causing waterlogging that reduces the available heat transfer area and hampers performance.

Engineers must consider several variables for accurate sizing. Fluid characteristics like flow rate and viscosity are crucial. Higher fluid flow rates demand a larger heat exchanger to handle the volume while maintaining efficiency. Similarly, fluids with high viscosity resist flow, which can increase the pressure drop and necessitate a larger unit to compensate.

Note: Professional Sizing ToolsProfessionals rely on sophisticated software to perform these complex calculations and ensure optimal selection. These tools model performance based on specific operating conditions. Common examples include:

·SWEP DThermX: Recommends products for single-phase, condenser, and evaporator applications.

·Kelvion Select: Offers web-based configurators for both brazed and gasketed plate heat exchangers.

·Taco's Selection Apps: Provide tools for sizing both shell and tube and brazed plate models.

·Heatcraft Coil Calc: Generates detailed submittal packages for commercial coils with performance data and drawings.

Material Selection for Longevity

The materials used to construct commercial heat exchangers determine their durability, resistance to corrosion, and overall lifespan. The choice directly impacts maintenance needs and long-term return on investment. A material must be compatible with the process fluids, withstand operating temperatures and pressures, and facilitate efficient heat transfer.

A material's thermal conductivity measures its ability to transfer heat. Materials with high conductivity transfer heat more efficiently. However, conductivity must be balanced with other critical properties like strength and corrosion resistance.

| Material | Thermal Conductivity | Other Properties | Efficiency Impact |

|---|---|---|---|

| Copper | Excellent | Costly, antimicrobial | High efficiency, often used in HVAC and water applications. |

| Aluminum | Good | Lightweight, cost-effective | Good for applications where weight is a key factor, like aerospace. |

| Stainless Steel | Balanced | Durable, corrosion-resistant | The most common choice due to its excellent balance of properties. |

| Titanium | Moderate | Extremely corrosion-resistant | Ideal for harsh environments like saltwater, despite lower conductivity. |

Resistance to corrosion and fouling is paramount for longevity. Fouling is the accumulation of unwanted deposits on heat transfer surfaces, which insulates the surface and reduces efficiency. The right material can significantly slow this process. In sanitary industries like food, beverage, and pharmaceuticals, stainless steel or higher alloys are required for all surfaces that contact the product. These materials are easy to clean and resist scaling.

The following table outlines how different materials stand up to corrosive environments:

| Material | Corrosion Resistance Advantage |

|---|---|

| Carbon Steel | Cost-effective for non-corrosive fluids but rusts easily. |

| Stainless Steel (316) | Excellent general resistance, especially against pitting from chlorides. |

| Duplex Stainless Steel | Higher strength and superior resistance to stress corrosion cracking. |

| Nickel Alloys (e.g., Hastelloy) | Superior resistance to highly corrosive media and high temperatures. |

| Titanium | Exceptional resistance to seawater, chlorides, and oxidizing acids. |

| Copper Alloys | Good resistance to biofouling, making them useful in marine settings. |

Finally, many industries follow strict standards for material selection based on the specific service conditions. These guidelines ensure safety, reliability, and optimal performance in demanding applications.

| Service Condition | Preferred Materials |

|---|---|

| Natural Seawater | Copper-Nickel (Cu-Ni) 90/10; Titanium |

| Desalination | Titanium; 316L Stainless Steel; Cu-Ni 90/10 |

| Petrochemical Cooling | 316L/Duplex Stainless Steel; Titanium on seawater side |

Maintenance for Sustained Performance

Proper selection and sizing establish a heat exchanger's potential. Consistent maintenance, however, ensures that it delivers on its promise of long-term energy savings. Neglecting maintenance allows performance to degrade, erasing the benefits of the initial investment.

The Critical Role of Regular Cleaning

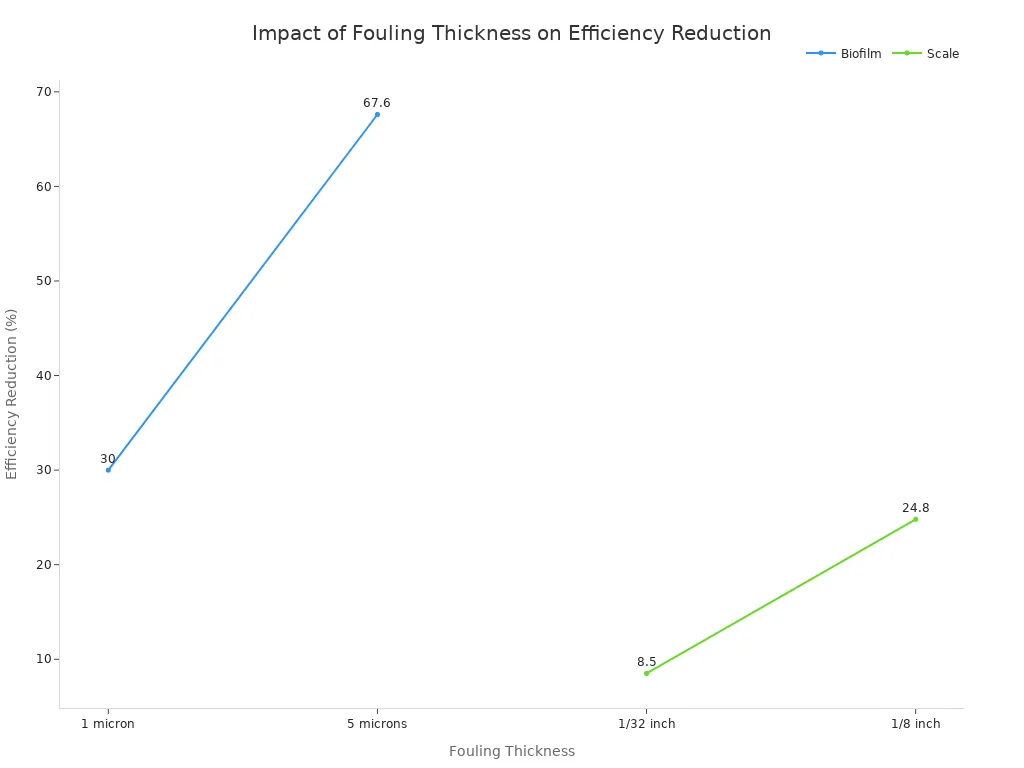

Fouling is the primary enemy of heat exchanger efficiency. It is the accumulation of unwanted deposits like minerals, microorganisms, or chemical residues on heat transfer surfaces. This buildup acts as an insulating layer, restricting heat flow and increasing energy consumption. Even a thin layer has a significant impact. For example, a 1/32-inch layer of mineral scale can reduce efficiency by 8.5%.

Different cleaning methods address fouling with varying success. While traditional hydroblasting reaches about 85% effectiveness, modern techniques like ultrasonic cleaning can restore surfaces to near 100% of their original performance. Regular cleaning removes these insulating layers, restores thermal efficiency, and prevents permanent equipment damage.

A Simple Maintenance Checklist

A proactive maintenance schedule is the best defense against performance loss. The ideal cleaning frequency depends on the operating environment. Systems in harsh environments may need quarterly cleaning, while others can operate longer. A simple, routine checklist helps technicians spot issues early.

Key Maintenance Tasks:

·Inspect the unit externally for any leaks, corrosion, or damage.

·Monitor pressure gauges and thermometers for deviations from normal operating levels. A pressure drop greater than 5 PSI often signals a problem.

·Check heat transfer surfaces for visible signs of fouling or scaling.

·Clean or flush the system to remove debris and buildup before it becomes severe.

·Record all maintenance activities and performance data to track the unit's health over time.

Commercial heat exchangers are a cornerstone of any modern energy strategy. They recover waste heat to reduce system loads, delivering a strong return on investment. A market projected to exceed $97 billion by 2030, supported by government incentives, highlights their growing importance. Proper selection, sizing, and maintenance are essential to unlocking these substantial savings.

FAQ

What is the typical payback period for a heat exchanger?

The payback period varies by application. Many projects see a return on investment in under two years. Some high-efficiency systems can achieve payback in just a few months.

How often should a commercial heat exchanger be cleaned?

Cleaning frequency depends on operating conditions. Harsh environments may require quarterly service. Systems in cleaner settings might only need annual cleaning to maintain peak performance and efficiency.

Can heat exchangers be used for cooling applications?

Yes, they are essential for cooling. Heat exchangers transfer unwanted heat from a process fluid to a cooler medium. This process reduces the load on primary cooling systems.