5 key roles of plate heat exchanger gaskets.

Plate heat exchanger gaskets perform 5 key roles: ...

More

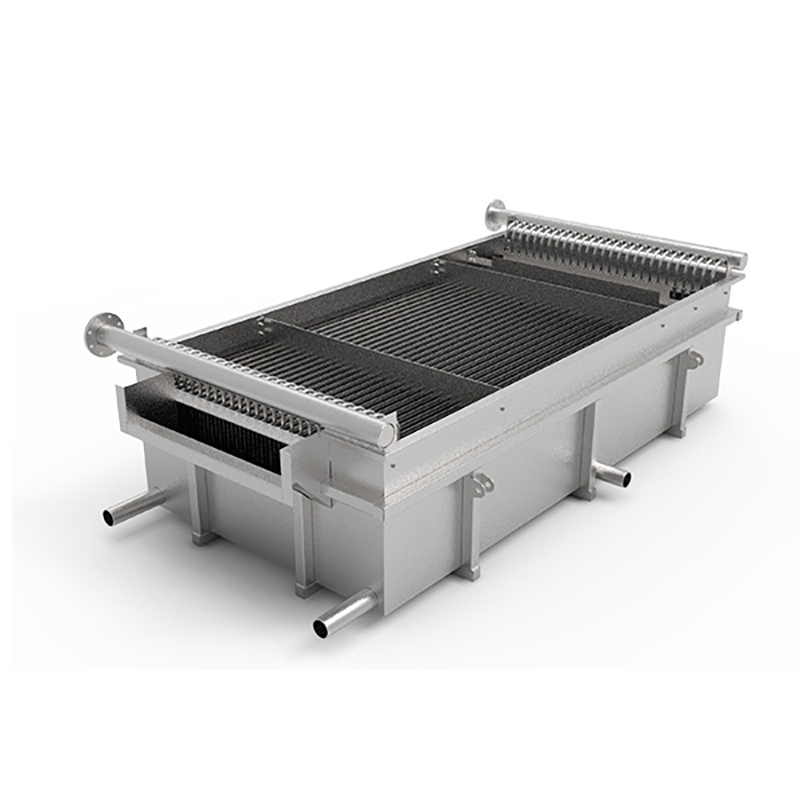

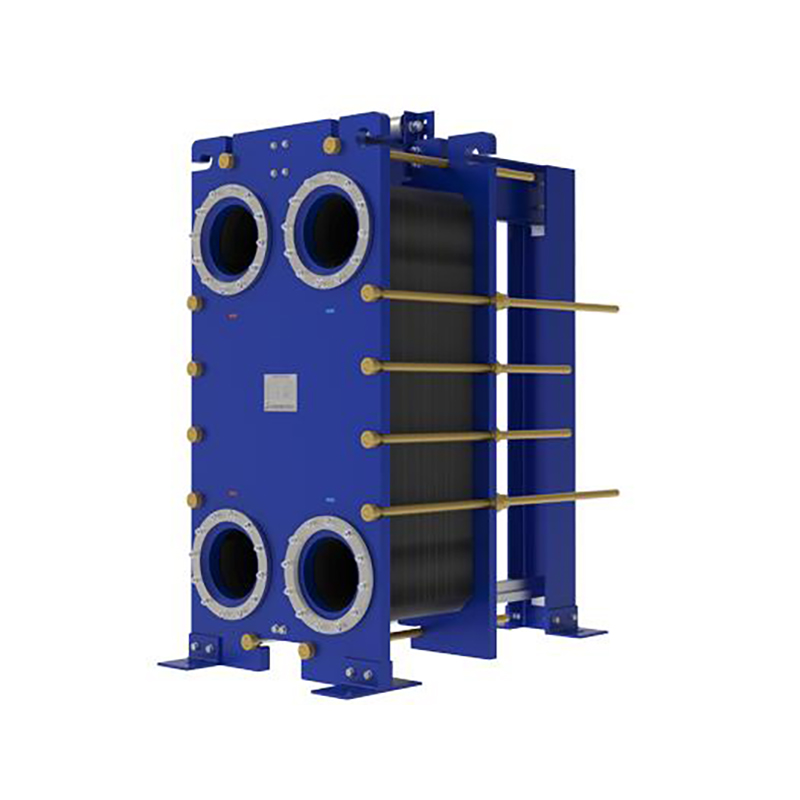

A cooling plate heat exchanger operates on the principle of indirect heat transfer between two fluids through a series of thin, corrugated metal plates. These plates are assembled in a pack, mounted on a frame, and compressed between a fixed head and movable pressure plate. Each plate is fitted with a gasket that seals the channels and directs the fluids into alternating passages. The highly turbulent flow induced by the plate corrugations maximizes the heat transfer coefficient, allowing for efficient temperature control. The compact design provides a large surface area within a small volume, enabling rapid and effective cooling of process fluids, oils, or water-glycol mixtures in various industrial systems. The arrangement ensures the hot and cold media remain completely separate, preventing cross-contamination while facilitating optimal thermal exchange.

Utilizing a cooling plate heat exchanger offers significant advantages in industrial applications, primarily due to its superior efficiency, compact footprint, and operational flexibility. These systems are engineered to handle high thermal loads with a smaller surface area compared to shell-and-tube models, often achieving heat transfer coefficients 3-4 times higher, which translates to a 50-60% reduction in required space. Their modular design allows for easy capacity expansion or reduction by simply adding or removing plates, providing exceptional scalability to meet changing process demands. Maintenance is simplified as the plate pack can be opened for inspection and mechanical cleaning, reducing downtime. The high turbulence minimizes fouling and ensures a more stable performance over time. Industries from manufacturing and power generation to marine and HVAC leverage these exchangers for precise temperature control, which is critical for process stability, equipment protection, and energy conservation. Real-world data from installed systems consistently show energy savings of 10-30% due to the reduced approach temperatures and lower pumping power requirements, making them a cost-effective and reliable solution for demanding cooling tasks.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Plate heat exchanger gaskets perform 5 key roles: ...

MoreAPI 662 defines standards for plate heat exchanger...

More

You can see clear differences between welded block...

More

The dimple plate heat exchanger, also known as the...

More

A gasket in heat exchanger seals surfaces, blocks ...

More

Shanghai Heat Transfer stands out with its ISO9001...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

Michael Rodriguez

Facilities ManagerThis cooling plate heat exchanger is incredibly efficient and robust. It significantly improved our process cooling, reduced energy consumption, and has been running flawlessly for months with minimal maintenance. A fantastic investment for any industrial application.

Sarah Chen

HVAC EngineerPrecise temperature control and a compact design. We integrated this plate heat exchanger into a new commercial building's HVAC system, and it performs exceptionally well under varying loads. The build quality is outstanding.

David Kim

Lead TechnicianInstallation was straightforward, and the performance is top-notch. It handles the heat rejection from our hydraulic systems much more effectively than our old unit. The only reason for 4 stars is that the initial delivery was a week later than promised.

Jennifer Williams

Plant OperatorThe durability of this heat exchanger is impressive. It operates 24/7 in a harsh environment with corrosive elements, and it shows no signs of wear. It's reliable, efficient, and has drastically reduced our downtime for cooling-related issues.