5 key roles of plate heat exchanger gaskets.

Plate heat exchanger gaskets perform 5 key roles: ...

More

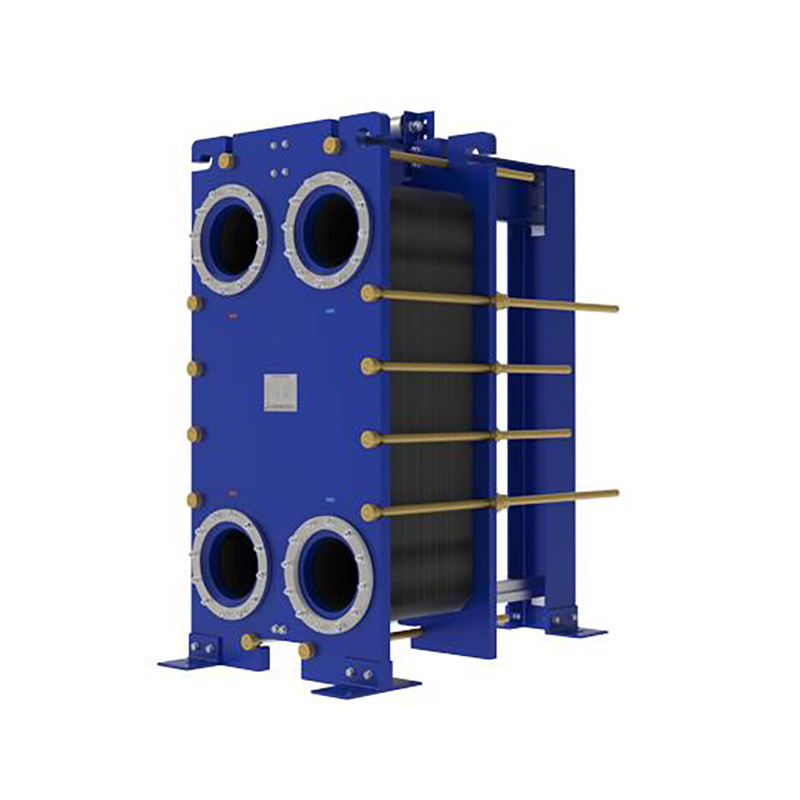

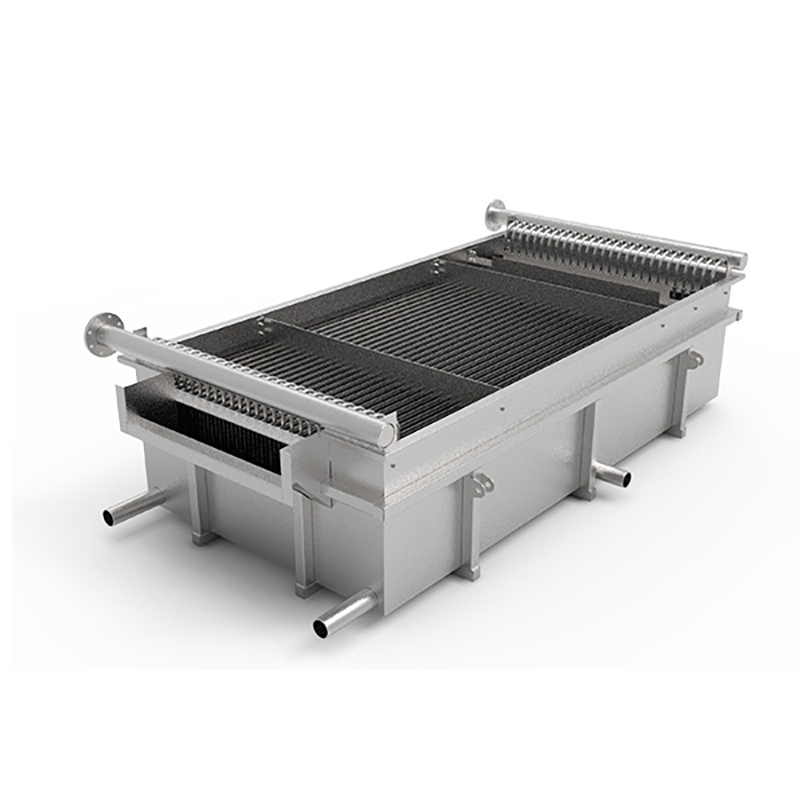

A Counter Current Plate Heat Exchanger is a type of heat transfer equipment where two fluids flow in opposite directions through alternating channels formed between corrugated metal plates. This specific design is engineered to maximize the temperature difference between the hot and cold streams across the entire length of the unit, driving superior thermal efficiency compared to traditional co-current or shell-and-tube models. The core component is a pack of pressed plates, sealed by gaskets, clamped together in a frame, creating a highly compact and modular system. Renowned for their effectiveness in close temperature approach applications, sometimes as low as 1°C, these exchangers are the industry standard for duties requiring high heat recovery, precise temperature control, and minimal energy waste. They are pivotal in sectors like HVAC, chemical processing, food and beverage, pharmaceuticals, and marine engineering, where optimizing energy use is critical for operational cost and environmental impact.

The exceptional performance of a counter current plate heat exchanger stems directly from its fundamental design principle: opposing fluid flow. As the hot fluid enters at one end and flows through its designated channels, it transfers heat to the cold fluid, which is simultaneously entering at the opposite end and moving in the reverse direction. This counter-flow arrangement maintains a significantly more consistent and favorable log mean temperature difference (LMTD) across the entire transfer surface than parallel flow designs. In a parallel flow system, the temperature difference is highest at the inlet and decreases rapidly, limiting the potential heat recovery. In contrast, the counter-flow configuration allows the exiting hot fluid, now cooled, to interact with the incoming cold fluid, which is at its lowest temperature. Simultaneously, the exiting cold fluid, now heated, interacts with the incoming hot fluid at its peak temperature. This results in a much more uniform driving force for heat transfer from start to finish. According to performance data from manufacturers like Alfa Laval, SWEP, and APV, this enables temperature cross situations, where the outlet temperature of the cold stream can actually exceed the outlet temperature of the hot stream, a feat impossible in co-current setups. The high turbulence induced by the plate corrugations also drastically improves the heat transfer coefficients, reducing the required surface area. This combination of high efficiency and compactness makes it the preferred choice for applications like district heating, engine cooling, and effluent cooling, where maximizing energy recovery from a low-grade heat source is paramount.

The operational principle of a counter current plate heat exchanger is a precise orchestration of fluid dynamics and thermal conduction. The process begins with the hot and cold fluids being directed into the exchanger at opposite ends. The plate pack, compressed within the frame, features port holes that create continuous manifolds to distribute the fluids into the alternating channels between the plates. Specially designed gaskets ensure the fluids are channeled correctly and prevent them from mixing. As the fluids are pumped through their respective narrow, corrugated passages, the plate pattern forces them into a turbulent flow regime. This turbulence is crucial as it minimizes the stagnant boundary layer at the plate surface, which acts as an insulator, thereby greatly enhancing the rate of heat conduction through the thin metal plate. The heat energy moves from the hot stream, through the plate, and into the cold stream without the fluids ever making physical contact. The counter-current flow path means that at any given point along the length of the exchanger, there is always a substantial temperature difference between the two fluids, which is the driving force for the heat transfer. This allows for a very high degree of temperature change in both fluids. The process continues until the fluids reach the ends of their respective flow paths; the now-cooled hot fluid exits at the opposite end from where the cold fluid entered, and the now-heated cold fluid exits at the opposite end from where the hot fluid entered, completing the efficient thermal exchange cycle.

A detailed breakdown of the working mechanism involves several key physical and engineering factors. The corrugated plate design, often with herringbone patterns, is not random; the chevron angle is engineered to induce specific levels of turbulence and pressure drop. Plates with a high chevron angle provide high heat transfer coefficients and high resistance (pressure drop), suitable for media with low viscosity. Conversely, a low angle offers lower heat transfer with significantly lower pressure drop, ideal for high-viscosity fluids or applications where pumping power is a constraint. The narrow gap between plates, typically 1.5 to 5 mm, ensures a high fluid velocity which further promotes turbulence and fouling resistance. Real-world operational data, such as that from SWEP product catalogs, shows that a typical brazed plate heat exchanger (BHE) can achieve heat transfer coefficients (U-values) ranging from 3,000 to 7,000 W/m²°C for water-to-water applications, vastly outperforming shell-and-tube exchangers which typically achieve 800-1,500 W/m²°C. This high efficiency directly translates to a smaller required heat transfer area for the same duty, leading to a compact, lightweight, and cost-effective unit. The working pressure and temperature limits are defined by the gasket material (for gasketed types) or the braze material (for welded types), with standard nitrile gaskets handling up to 150°C and special materials like EPDM or graphite extending the range. The modular nature of the plate pack allows for easy capacity adjustment by simply adding or removing plates, providing exceptional operational flexibility to meet changing process demands.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Plate heat exchanger gaskets perform 5 key roles: ...

MoreAPI 662 defines standards for plate heat exchanger...

More

Compare top frame plate heat exchanger models for ...

More

You can see clear differences between welded block...

More

The dimple plate heat exchanger, also known as the...

More

A gasket in heat exchanger seals surfaces, blocks ...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

Michael Reynolds

Process EngineerThis counter current plate heat exchanger has dramatically improved our system's thermal efficiency. The compact design saves significant space, and the heat transfer rates are exceptional. A fantastic piece of engineering.

Sarah Chen

Plant ManagerIncredibly robust and reliable. We've been running this unit in our dairy processing plant for over a year with zero maintenance issues. The counter-current flow design ensures perfect pasteurization temperatures every time. Highly recommended.

David Rodriguez

HVAC SpecialistExcellent performance for district heating recovery applications. The plates are well-constructed and easy to access for cleaning. Installation was straightforward. A very efficient and cost-effective solution.

James Wilson

Maintenance SupervisorThe serviceability of this heat exchanger is top-notch. The ability to easily add or remove plates to adjust capacity is a huge advantage for our evolving needs in the pharmaceutical industry. A smart long-term investment.