Plate Heat Exchanger Applications in Food Processing

Plate heat exchangers deliver high thermal efficie...

More

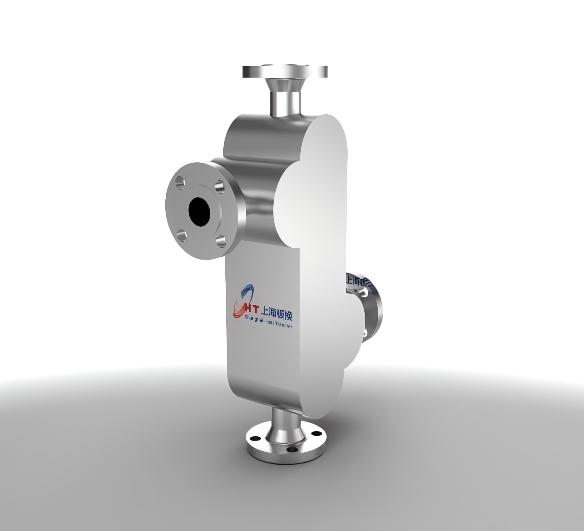

A countercurrent heat exchanger is a highly efficient thermal transfer device designed to maximize energy recovery by flowing two fluids in opposite directions. This configuration creates a sustained temperature gradient along the entire length of the exchanger, enabling optimal heat transfer between the fluids. Unlike parallel-flow systems, where temperatures equilibrate quickly, countercurrent designs maintain a consistent differential, allowing hotter fluids to release more energy to cooler ones. Industries such as chemical processing, power generation, and HVAC rely on this principle to reduce energy waste and operational costs. The design’s effectiveness is quantified by its logarithmic mean temperature difference (LMTD), which ensures superior performance in applications requiring precise thermal management.

Modern countercurrent heat exchangers utilize advanced materials like stainless steel, titanium, or ceramics to withstand extreme temperatures and corrosive environments. Computational fluid dynamics (CFD) simulations further optimize flow paths, minimizing pressure drops while maximizing heat recovery. For example, in district heating systems, countercurrent exchangers achieve up to 90% thermal efficiency, significantly lowering carbon emissions. Real-world data from industrial plants shows energy savings of 20–30% compared to co-current designs. Regulatory standards like ASME and ISO 9001 certify these systems for safety and performance, making them indispensable in sustainable engineering.

Countercurrent heat exchangers are preferred for their unmatched efficiency, scalability, and adaptability across diverse applications. Their ability to maintain high thermal gradients ensures minimal energy loss, critical for industries like oil refining, where heat recovery directly impacts profitability. Studies by the U.S. Department of Energy highlight that countercurrent systems reduce fuel consumption by 15–25% in boiler flue gas applications. Additionally, their compact design saves space and installation costs, particularly in modular plants.

Environmental benefits further drive adoption. For instance, wastewater treatment plants use countercurrent exchangers to recover heat from effluent streams, cutting heating energy demands by 40%. In renewable energy systems, such as geothermal loops, they enhance output by 10–15%. Durability is another advantage; materials like duplex steel extend lifespans beyond 20 years, reducing lifecycle costs. Market research from Grand View Research projects the global heat exchanger market to reach $22.3 billion by 2027, with countercurrent models leading growth due to stringent energy regulations and corporate sustainability goals.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Plate heat exchangers deliver high thermal efficie...

More

Understanding welded heat exchanger's unique const...

More

Printed circuit heat exchangers (PCHEs) are a cutt...

More

Recently, SHPHE received repeat order from custome...

More

A commercial plate heat exchanger offers industrie...

More

PCHEs routinely operate at temperatures up to 850 ...

MoreExplore more content related to foreign trade services