Leakage free air preheater picks that stop waste now

Leakage free air preheater solutions from top bran...

More

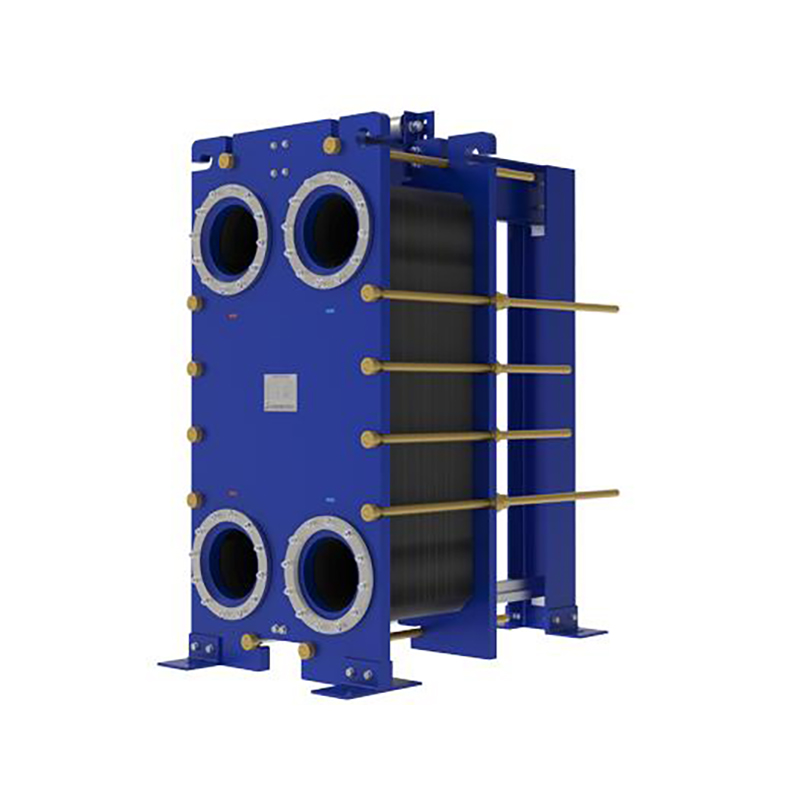

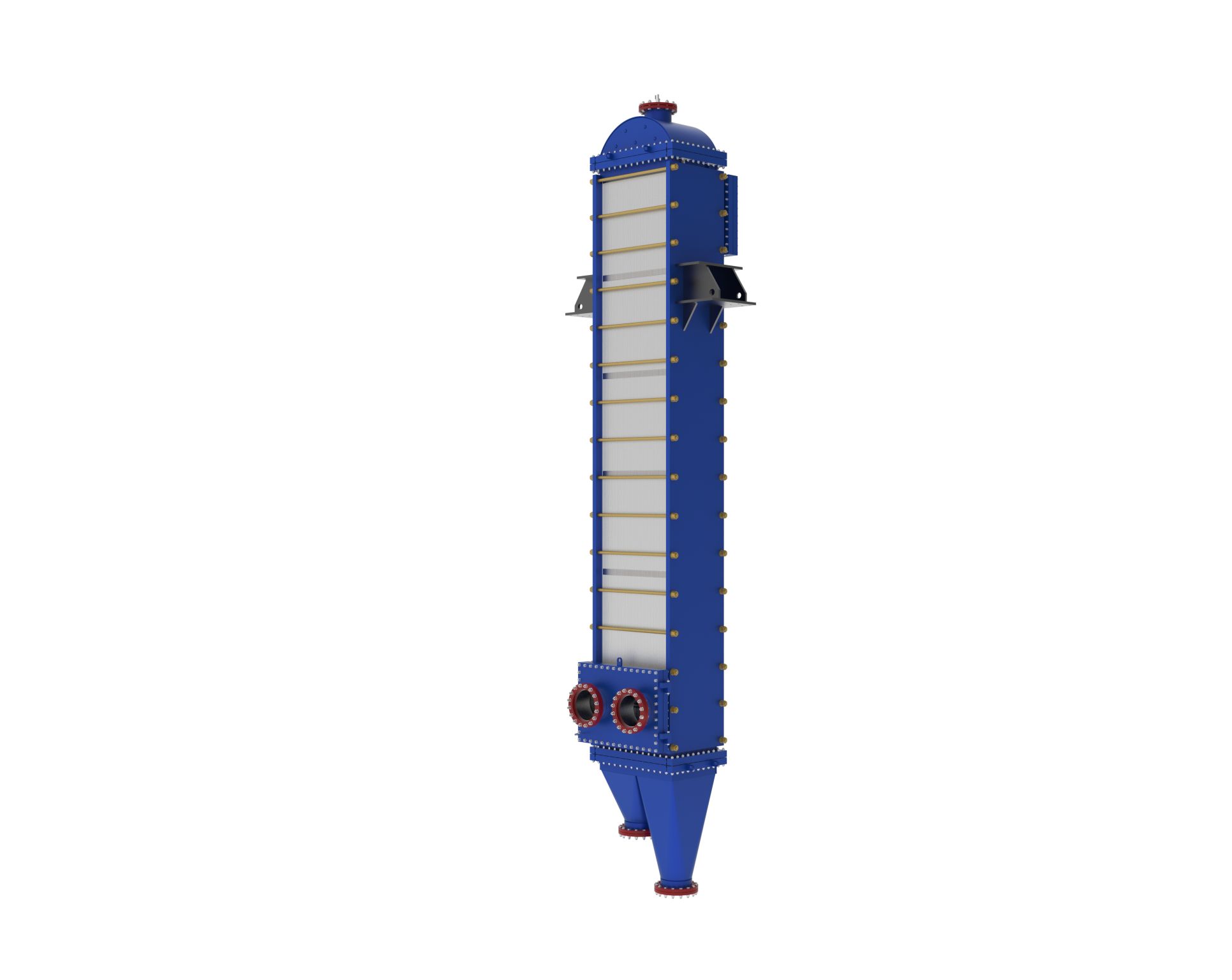

The economizer and air preheater are critical heat recovery components in industrial boiler systems and thermal power plants, designed to capture waste heat from flue gases and improve overall energy efficiency. An economizer is a heat exchanger that preheats the feedwater entering the boiler by transferring residual thermal energy from the flue gas exhaust, typically increasing water temperature before it reaches the evaporation stage. This process reduces the fuel required to convert water to steam, directly lowering energy consumption. An air preheater, often a rotary regenerative or tubular type, further extracts heat from the flue gases to warm the combustion air supplied to the boiler's burners. By raising the air temperature, it ensures more complete and efficient fuel combustion, which enhances thermal efficiency and reduces unburned fuel losses. Both devices operate on the counter-flow principle, maximizing heat transfer efficiency. Industrial data from power generation facilities, such as those reported by the U.S. Energy Information Administration (EIA), indicate that economizers can improve boiler efficiency by 4-6%, while air preheaters contribute an additional 2-4% efficiency gain. For example, in a typical 500 MW coal-fired power plant, the integration of these systems can recover up to 300 MW of thermal energy that would otherwise be wasted, reducing CO2 emissions by approximately 200,000 tons annually. Modern designs incorporate advanced materials like corrosion-resistant alloys and modular structures to handle high sulfur content in fuels and minimize maintenance costs. These systems are essential in meeting stringent environmental regulations, such as the EPA's Clean Air Act standards, by enabling lower flue gas temperatures and reducing the load on downstream pollution control equipment like scrubbers and electrostatic precipitators.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Leakage free air preheater solutions from top bran...

More.jpg)

Plate air preheaters transform industrial processe...

More

Maximize energy efficiency and cut costs by select...

More

Commercial heat exchangers boost energy efficiency...

MoreModern HVAC heater exchangers in 2025 offer superi...

More

Printed circuit heat exchanger advancements in 202...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

Michael Chen

Plant EngineerThe economizer has significantly improved our boiler efficiency, leading to substantial fuel savings. The build quality is exceptional and it integrated seamlessly with our existing system. A fantastic investment for any steam plant.

Sarah Johnson

Maintenance ManagerThis air preheater is incredibly robust and has drastically reduced our stack gas temperatures. The heat recovery has cut our furnace's fuel consumption by over 15%. Installation was straightforward and it has required zero maintenance since.

David Rodriguez

Facility Operations DirectorWe installed both the economizer and air preheater as a package. The combined effect on our thermal efficiency is remarkable. The only reason for not giving a 5 is the lead time was longer than initially quoted, but the product performance itself is outstanding.

Emily Wang

Project EngineerAs an energy consultant, I specify these components often. This manufacturer's economizer and air preheater are top-tier. Their performance data is accurate, and they are built to last in harsh environments. Highly reliable for critical heat recovery applications.