Emerging Technologies in Energy Efficient Heat Exchangers Supporting Global Sustainability

Energy Efficient Heat Exchanger Fundamentals

Definition and Function

An energy efficient heat exchanger is a device that transfers heat between two or more fluids without mixing them. Engineers design these systems to maximize heat transfer while minimizing energy loss. Most heat exchangers use metal plates, tubes, or fins to separate the fluids and allow heat to move from the hotter fluid to the cooler one. These devices appear in many industries, ·including power generation, HVAC, and chemical processing.

·Heat exchangers help save energy by reusing heat that would otherwise go to waste.

·The main function of an energy efficient heat exchanger is to improve thermal performance. This means the system can move more heat using less energy. As a result, companies can lower ·their fuel use and reduce operating costs.

Significance in Modern Energy Systems

Modern energy systems rely on heat exchangers to boost efficiency and support sustainability goals. Power plants use them to recover waste heat and generate more electricity from the same fuel. Factories install these devices to reuse heat in production lines, which cuts down on emissions.

Key benefits of energy efficient heat exchangers include:

·Lower greenhouse gas emissions

·Reduced energy consumption

·Improved process reliability

·A well-designed heat exchanger can make a big difference in meeting global energy targets. Many industries now see these devices as essential tools for building a cleaner future.

Challenges in Energy Efficiency and Sustainability

Limitations of Conventional Heat Exchangers

Conventional heat exchangers often struggle to meet modern efficiency standards. Many older designs use bulky materials and have limited surface area for heat transfer. These systems can lose significant amounts of energy during operation. Engineers find that fouling, or the buildup of unwanted materials on heat transfer surfaces, reduces performance over time. Maintenance becomes more frequent and costly as a result.

Some common limitations include:

·High energy loss due to poor thermal conductivity

·Large physical footprint, making installation difficult in compact spaces

·Limited ability to recover low-grade waste heat

These drawbacks highlight the need for advanced solutions in today’s industries.

Environmental and Economic Impacts

Inefficient heat exchangers contribute to higher fuel consumption and increased greenhouse gas emissions. Companies that rely on outdated systems often face rising energy bills and stricter environmental regulations. The use of more fuel not only raises costs but also puts extra pressure on natural resources.

A comparison of impacts:

| Factor | Conventional Systems | Modern Solutions |

|---|---|---|

| Energy Consumption | High | Lower |

| Emissions | Increased | Reduced |

| Maintenance Costs | Frequent | Less Frequent |

An energy efficient heat exchanger helps companies lower their carbon footprint and save money. By upgrading to newer technologies, industries can support both environmental goals and economic growth.

Innovations in Energy Efficient Heat Exchanger Technology

Advanced Materials and Coatings

Engineers have introduced new materials to improve the performance of heat exchangers. They use alloys with high thermal conductivity, such as aluminum and copper, to transfer heat more efficiently. Some teams select composite materials that resist corrosion and fouling. These choices extend the lifespan of the equipment and reduce maintenance needs.

Special coatings also play a key role. Anti-fouling coatings prevent the buildup of scale and biological matter. Hydrophobic surfaces help fluids flow smoothly, which increases heat transfer rates. These innovations allow an energy efficient heat exchanger to operate at peak performance for longer periods.

Smart Systems: IoT and AI Integration

Digital technology has transformed the way industries monitor and control heat exchangers. Sensors collect real-time data on temperature, pressure, and flow rates. IoT platforms send this information to cloud-based systems for analysis.

Artificial intelligence (AI) algorithms process the data and predict when maintenance is needed. They also optimize operating conditions to maximize efficiency. This approach helps companies avoid unexpected breakdowns and reduce energy waste.

·IoT sensors detect early signs of fouling or leaks.

·AI systems adjust settings for changing process demands.

·Remote monitoring allows quick response to issues.

A smart energy efficient heat exchanger can adapt to different loads and conditions, which supports both reliability and sustainability.

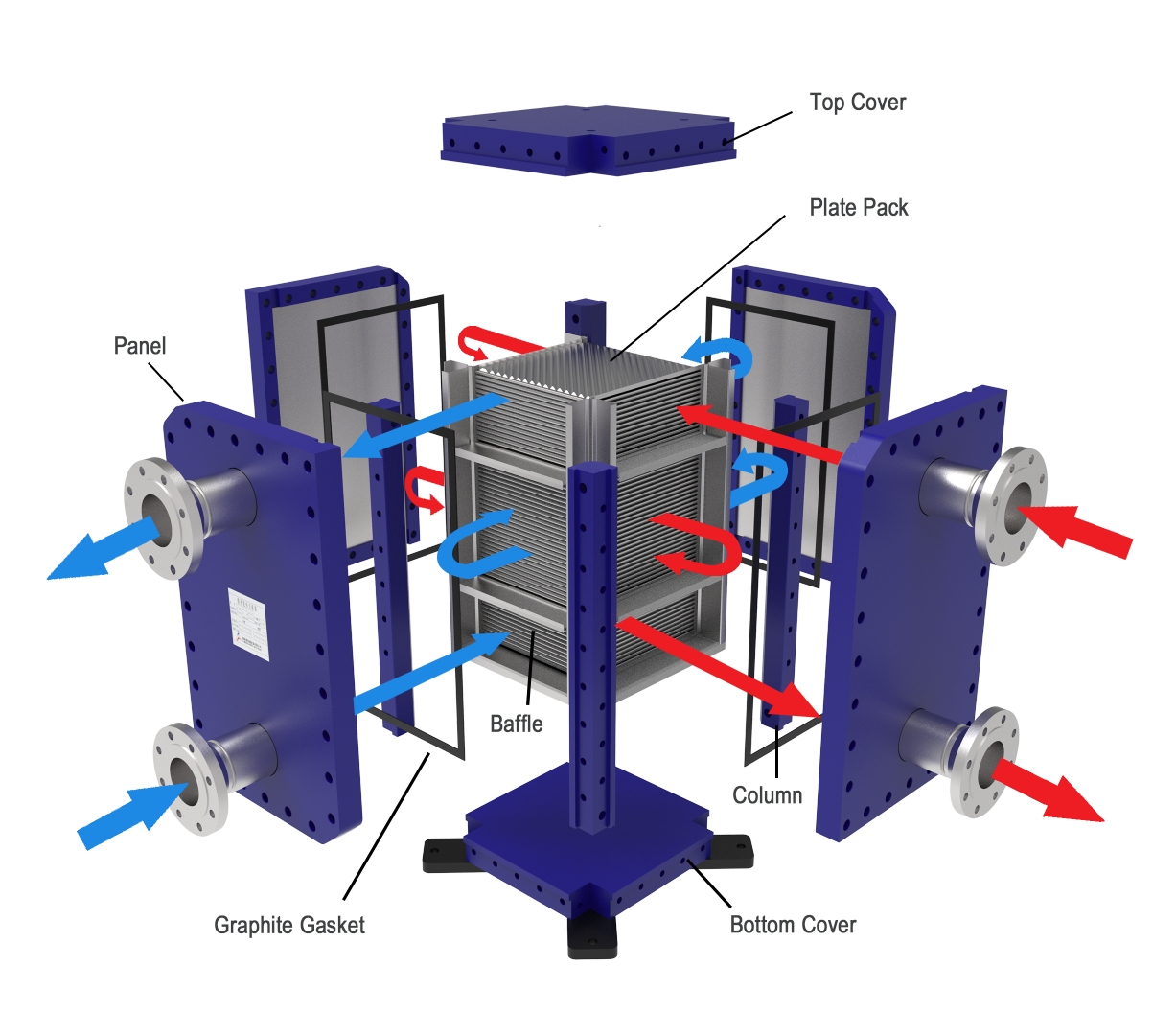

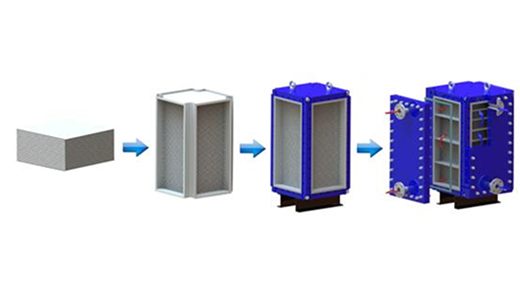

Compact and Modular Designs

Space often limits the installation of traditional heat exchangers. Modern designs address this challenge by using compact and modular units. Engineers create plate heat exchangers with thin, stacked plates that offer a large surface area in a small footprint. Modular systems allow companies to add or remove units as needed.

These designs make it easier to upgrade existing facilities. They also reduce installation time and costs. Compact heat exchangers fit into tight spaces, such as ships or small factories, without sacrificing performance.

Waste Heat Recovery and Renewable Integration

Many industries produce waste heat during their operations. Advanced heat exchangers capture this energy and reuse it elsewhere in the process. This practice reduces fuel consumption and lowers emissions.

Some systems integrate with renewable energy sources. For example, solar thermal collectors can supply heat to an energy efficient heat exchanger, which then distributes it throughout a building or factory. This integration supports the shift toward cleaner energy and helps companies meet sustainability targets.

| Application Area | Benefit |

|---|---|

| Industrial Processes | Lower fuel use, fewer emissions |

| Buildings | Improved heating efficiency |

| Power Generation | Enhanced energy recovery |

By recovering waste heat and using renewables, industries can make significant progress toward global sustainability goals.

Sustainability Impact of Energy Efficient Heat Exchangers

Reducing Carbon Emissions

Energy efficient heat exchangers help industries lower carbon emissions. These devices recover and reuse heat that would otherwise escape into the environment. Power plants, factories, and commercial buildings use them to cut fuel consumption. As a result, they release fewer greenhouse gases. Many companies report significant reductions in their carbon footprint after installing advanced heat exchangers.

Lowering Energy Costs

Businesses save money by using energy efficient heat exchangers. These systems transfer heat more effectively, which means less energy is needed to achieve the same results. Companies often see lower utility bills and reduced operating expenses. The initial investment pays off quickly through ongoing savings. Facility managers track energy use and notice improvements after upgrading their equipment.

| Benefit | Impact on Costs |

|---|---|

| Improved heat transfer | Lower fuel expenses |

| Reduced waste | Fewer repairs |

| Smart controls | Optimized usage |

Enabling Circular Economy Practices

Energy efficient heat exchangers support circular economy practices. They allow industries to reuse heat within their processes, minimizing waste. Factories can redirect recovered energy to other operations, creating a closed-loop system. This approach conserves resources and reduces the need for new energy inputs. Companies that adopt these practices contribute to a more sustainable future.

Regulatory Trends and Industry Adoption

Global Standards and Incentives

Governments and international organizations set strict standards for heat exchanger efficiency. The International Organization for Standardization (ISO) publishes guidelines that manufacturers follow to ensure safety and performance. The American Society of Mechanical Engineers (ASME) also provides codes for design and operation. These standards help companies produce reliable equipment.

Many regions offer incentives to encourage the adoption of advanced technologies. Agencies provide tax credits, grants, and rebates for facilities that install energy efficient heat exchangers. Some countries require industries to meet minimum efficiency targets. These policies drive innovation and support sustainability goals.

| Region | Incentive Type | Example Benefit |

|---|---|---|

| North America | Tax Credit | Reduced installation cost |

| Europe | Grant | Funding for upgrades |

| Asia-Pacific | Rebate | Lower purchase price |

Industry Implementation and Success Stories

Industries across the globe invest in new heat exchanger technologies. Chemical plants upgrade systems to reduce energy use and meet emission targets. Food processing facilities install compact units to save space and improve reliability. Power generation companies recover waste heat to boost output.

A leading beverage manufacturer replaced old equipment with an energy efficient heat exchanger. The company reported a 20% drop in energy costs and met local emission standards. Another example comes from a steel plant that used smart monitoring to prevent downtime and extend equipment life.

Innovations in energy efficient heat exchanger technology help industries lower emissions and save energy. Future advancements promise even greater sustainability benefits. Companies that invest in these solutions support global environmental goals. Every organization can make a difference by choosing sustainable technologies for their operations.

FAQ

How do smart heat exchangers improve sustainability?

IoT sensors and AI optimize heat transfer, reduce energy waste, and predict maintenance needs. These features help companies meet sustainability goals faster.

Are energy efficient heat exchangers expensive to install?

| Factor | Impact |

|---|---|

| Initial Cost | Moderate |

| Long-term Save | Significant |

Companies often recover costs through lower energy bills and reduced maintenance expenses.