Essential Guide to Maintaining Wide Gap Heat Exchangers in Sugar Plants

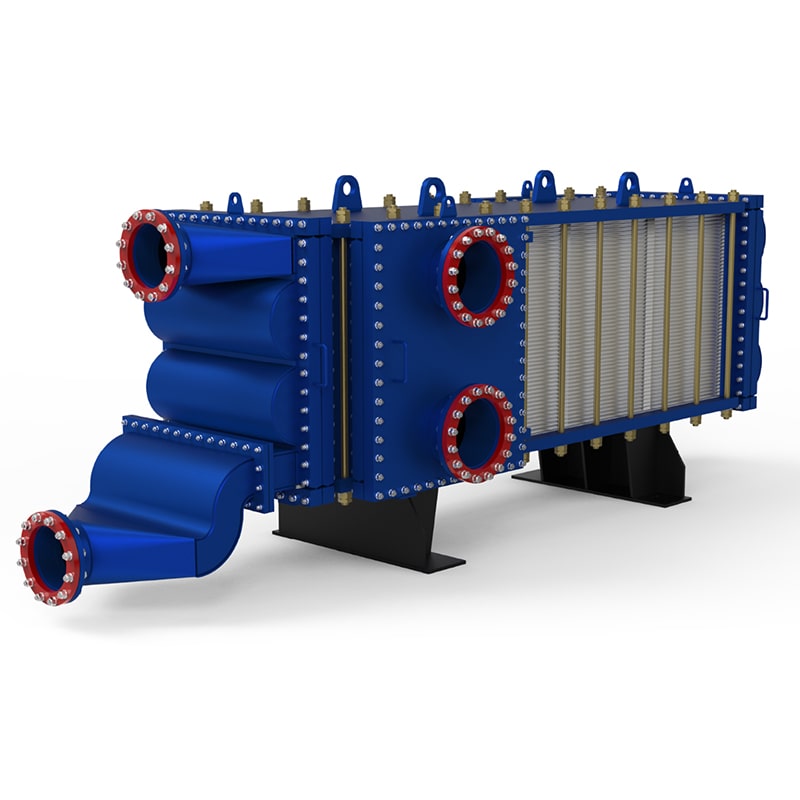

You keep your sugar plant running smoothly when you maintain your wide gap heat exchangers. Thick, particle-filled liquids challenge your process and demand a comprehensive understanding of heat exchangers. Shanghai Plate Heat Exchanger’s Wide Gap Welded Plate Heat Exchanger meets the unique needs of Sugar juice heater wide gap applications.

Why Maintenance Matters

Efficiency and Product Quality

You rely on wide gap heat exchangers to keep your sugar plant running at maximum efficiency. These advanced systems handle fibrous and viscous fluids, which are common in sugar processing. Their unique design minimizes fouling and clogging, so you get consistent heating and reliable thermal performance. When you maintain your heat exchangers, you protect the quality of your processed sugar. The heating process stays effective and steady, which means your final product meets high standards every time.

Tip: Regular cleaning and inspection help you avoid unexpected drops in operational efficiency. You can spot issues early and keep your equipment working at its best.

Wide gap heat exchangers are crucial for maintaining product quality.

They enhance safety in your operations.

They contribute to high energy efficiency, reducing operational costs.

Failure to maintain them can result in significant production losses.

Reducing Costs and Downtime

You save money and avoid costly shutdowns when you follow a maintenance routine. Wide gap heat exchangers are designed for fluids with solids or fibers, so their wide channels minimize clogging and reduce maintenance costs. You also benefit from their energy conserving features, which help you lower your utility bills.

Most sugar refineries choose wide gap heat exchangers for their unique configuration.

These systems help you save on operational and maintenance costs.

You keep your process running smoothly and avoid downtime.

When you prioritize maintenance, you achieve maximum efficiency and protect your investment. You ensure your plant operates reliably and meets production goals.

Wide Gap Heat Exchanger Overview

Identifying Cleaning Needs

You must recognize when your wide gap heat exchanger needs cleaning. Watch for signs like reduced heat transfer, increased pressure drop, or uneven temperature readings. These changes often mean fouling or scaling has started to build up inside the channels. You should also monitor for any unusual noises or vibrations during operation. These can signal blockages or deposits that restrict fluid flow.

Regular service and maintenance help you catch these issues early. Set clear service intervals based on your plant’s workload and the type of fluids you process. If you notice a drop in efficiency or see visible residue during inspections, plan a cleaning session right away.

Tip: Keep a log of performance data. Compare current readings with baseline values to spot trends and schedule cleaning before problems grow.

Cleaning Methods

You have several effective cleaning methods for wide gap heat exchangers in sugar plants:

Mechanical Flushing: Use water or a soft brush to remove loose debris from the wide gap channels. The openable design of the Wide Gap Welded Plate Heat Exchanger makes this process straightforward. You can access the plates easily and clear out fibers or particles without damaging the surfaces.

Chemical Cleaning: Apply food-grade cleaning agents through a cleaning-in-place (CIP) system. This method dissolves mineral scale and organic buildup. Specialized CIP machines circulate the cleaning solution, ensuring all surfaces get treated without disassembly.

Ultrasonic Cleaning: Use ultrasonic waves to dislodge stubborn deposits. This method works well for hard-to-reach areas and ensures thorough cleaning without harsh chemicals.

Choose cleaning agents that match the materials in your heat exchanger. Stainless steel and duplex stainless steel resist corrosion, but you should always use food-safe chemicals to protect your product quality.

Note: Mechanical and chemical cleaning are the most common methods in sugar plants. You can alternate between them based on the level of fouling and the type of residue present.

Inspection and Monitoring

You need to inspect and monitor your heat exchanger regularly to prevent major failures. Schedule visual checks at least every five years, but perform routine monitoring much more often. Look for leaks, corrosion, or signs of wear during each inspection. The openable design of the Wide Gap Welded Plate Heat Exchanger allows you to access internal channels quickly, making inspections less time-consuming.

Continuous monitoring keeps your system efficient and reliable. Use distributed temperature sensors to track thermal performance in real time. Monitor fluid flow rates to ensure your heat exchanger matches your process needs. Pressure sensors can alert you to operational challenges, so you can act before efficiency drops. Data analytics tools help you spot trends and anomalies, allowing you to make informed decisions about maintenance and optimization.

Here is a summary of industry standards for maintaining wide gap heat exchangers in sugar processing plants:

Aspect | Description |

|---|---|

Efficiency | WideGap heat exchangers are designed for high heat transfer efficiency, especially with fibrous materials. |

Maintenance | The wider spacing allows for longer intervals between cleanings, reducing downtime. |

Waste Heat Utilization | Capable of using low-grade vapour from processes, optimizing heat recovery and saving valuable heat sources for other uses. |

Economic Recovery | Wide-gap plates help recover heat from waste streams, enhancing overall efficiency in sugar processing. |

Alert: Routine monitoring and timely inspections protect your investment and keep your plant running smoothly.

By following these steps, you ensure your wide gap heat exchanger delivers reliable performance and supports your plant’s production goals.

Troubleshooting Issues

Leaks and Reduced Flow

You may notice leaks or a drop in flow during your process. These problems often start with worn gaskets or residue on sealing surfaces. To troubleshoot, follow these steps:

Look for visible leaks around the gasket area.

Check gaskets for cracks, tears, or signs of wear.

Make sure the gasket matches the manufacturer's specifications.

Confirm that all bolts are tightened to the correct torque.

Clean the mating surfaces to remove any residue or corrosion.

Align the gasket properly in the flange grooves.

Apply lubricant if the manufacturer recommends it.

Replace any damaged gaskets.

Test the heat exchanger with a pressure test to confirm repairs.

Inspect for corrosion or rust on components.

Regular maintenance and inspections help you catch leaks early and keep your system running smoothly.

Persistent Fouling Solutions

Fouling is a common issue in sugar plants. Solids and minerals in molasses, such as calcium and magnesium, can build up on heat exchanger surfaces. This buildup blocks channels and reduces heat transfer efficiency. You can address persistent fouling by:

Using mechanical flushing to remove loose debris.

Applying food-grade chemical cleaners to dissolve scale.

Scheduling ultrasonic cleaning for hard-to-reach deposits.

Monitoring for pressure drops or uneven temperatures.

Choosing corrosion-resistant materials for long-term reliability.

If you see frequent fouling, review your cleaning schedule and water quality to prevent future problems.

When to Contact Shanghai Plate Heat Exchanger

You should contact Shanghai Plate Heat Exchanger if you face severe leaks, repeated fouling, or unexplained drops in performance. Their experts can help you diagnose complex issues, recommend upgrades, or provide replacement parts. When you work with professionals, you protect your investment and keep your process efficient.

Best Practices & Checklist

Preventive Routines

You keep your wide gap heat exchanger reliable by following preventive routines. Start with regular access to spare parts and service kits. Schedule routine maintenance and visual condition assessments. Use food-grade grease on moving parts to prevent contamination. Request troubleshooting support when you notice unusual changes in your process. Consider advanced services like plate reconditioning and integrity tests. Service agreements help you stay proactive about safety and uptime.

Accurate record keeping supports your maintenance program. Begin documentation at installation and update it with every change. Keep a performance log with details like blank-off pressures and heating rates.

Maintenance Checklist

You can use this quick-reference checklist to guide your ongoing care:

Maintenance Item | Description |

|---|---|

Tube Leak Detection | Inspect tubes for leaks using a tube leak detector to ensure efficient operation. |

Tube Removal | Use tools to safely remove damaged tubes from the tube sheets to prevent hazards. |

Tube Cleaning | Implement periodic cleaning of tubes using electric or pneumatic tube cleaners to maintain efficiency. |

Tube Plugs | Seal off leaky or damaged tubes to ensure proper functioning of the heat exchanger. |

Tube Pulling Tools | Utilize hydraulic or pneumatic tools for effective tube pulling operations. |

Weld Removal Tools | Remove welds around tubes to facilitate maintenance and replacement. |

Tube Internal Cutters | Use internal diameter cutters to assist in the removal of tubes. |

Tube Cleaning Accessories | Employ flexible shafts and various cleaning tools to clean tubes effectively. |

Staff Training

You improve results when you train your staff on maintenance routines. Teach them how to use cleaning tools and safety equipment. Show them how to recognize early signs of fouling or leaks. Encourage them to update maintenance records after every service. Well-trained staff help you keep your heat exchanger running efficiently and extend its service life.

You boost plant productivity and product quality when you maintain wide gap heat exchangers. Regular cleaning and inspections keep your process reliable. Upgrading to the Wide Gap Welded Plate Heat Exchanger from Shanghai Plate Heat Exchanger helps you achieve optimal performance. Consult experts and follow best practices to reach optimal performance every day.

Routine maintenance removes fouling and extends equipment life.

Expert support ensures your system meets production goals.

FAQ

How often should you clean a wide gap heat exchanger?

You should clean your wide gap heat exchanger every few months. Regular cleaning keeps your process efficient and helps prevent fouling or scaling.

What cleaning method works best for sugar plants?

Mechanical flushing works well for most sugar plants. You can also use chemical cleaning or ultrasonic cleaning for stubborn deposits.

Can you inspect the heat exchanger without disassembling it?

You can perform visual inspections through access ports. The openable design lets you check internal channels quickly and keep your process running smoothly.