Expert Advice on Cleaning and Maintaining Plate Air Preheaters

Why Maintenance Is Essential

Efficiency and Cost Savings

Regular maintenance of the Plate Air Preheater helps companies save money and energy. When operators keep the heat exchanger clean and free from blockages, the system transfers heat more effectively. This means less fuel is needed to reach the desired temperature. Lower fuel use leads to direct cost savings. Shanghai Heat Transfer recommends routine inspections to catch early signs of fouling or wear. By following a maintenance schedule, operators can avoid expensive repairs and unplanned downtime.

Tip: A well-maintained Plate Air Preheater can improve energy efficiency by up to 1% for every 18°C reduction in exhaust temperature.

Environmental Impact

Maintaining the Plate Air Preheater also supports environmental goals. Clean equipment recovers more waste heat, which reduces the amount of fuel burned and lowers emissions. The table below highlights key environmental benefits:

Benefit | Description |

|---|---|

Reduced Greenhouse Gas Emissions | By recovering waste heat, air preheaters lower overall energy consumption, reducing emissions. |

Improved Combustion Efficiency | Preheated air leads to more complete combustion, lowering emissions of CO, NOx, and SOx. |

Regulatory Compliance | Helps industries meet stringent environmental regulations through cleaner combustion practices. |

Shanghai Heat Transfer designs its Plate Air Preheaters to help industries meet strict environmental standards while improving operational efficiency.

Reliability and Longevity

Consistent maintenance extends the lifespan of the Plate Air Preheater. When operators check for leaks, corrosion, and gasket wear, they prevent small issues from becoming major failures. Reliable equipment means fewer interruptions and a safer work environment. Shanghai Heat Transfer’s modular design makes it easier to replace parts and perform routine checks, ensuring long-term performance and durability.

Plate Air Preheater Types and Issues

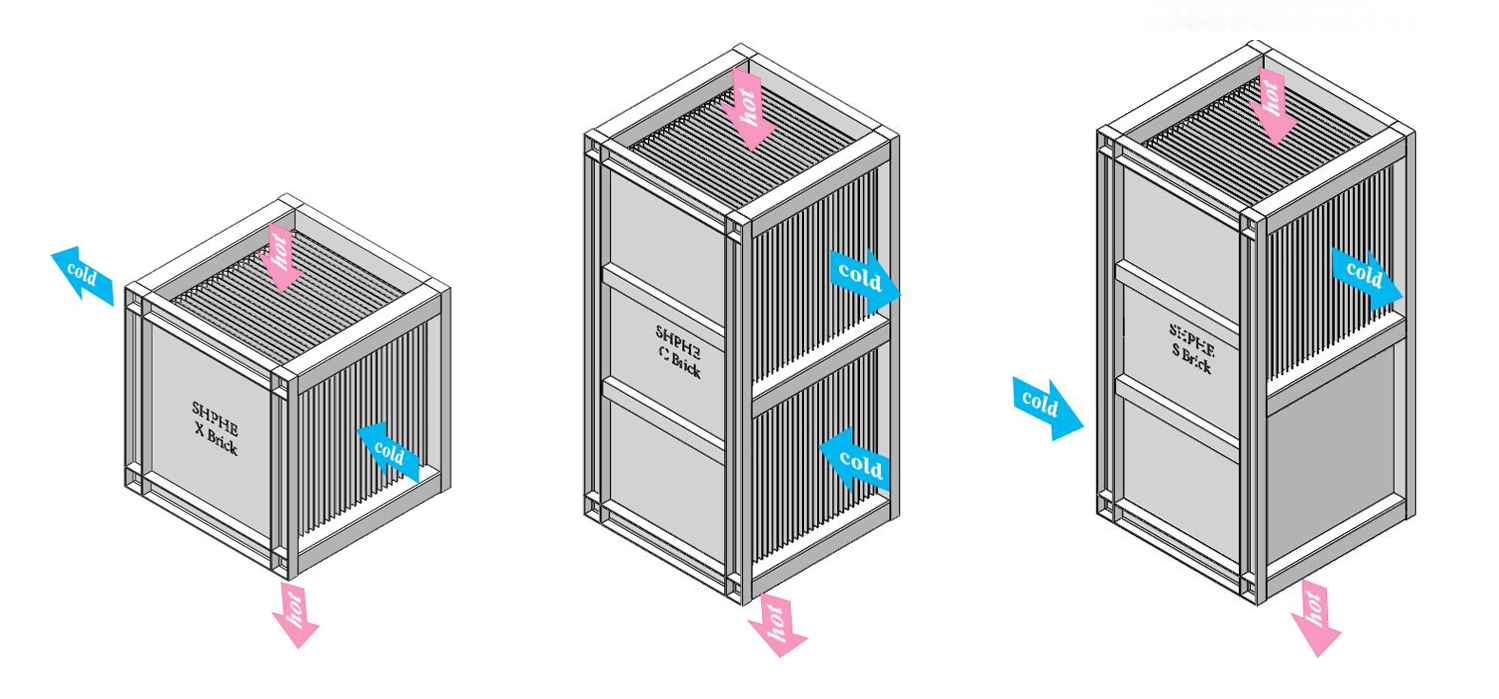

Common Designs

Industrial facilities use several types of plate air preheaters to recover waste heat and improve efficiency. The most common designs feature modular construction, which allows for easy transportation and on-site assembly. These units often use single-pass or multi-pass configurations to maximize heat transfer. Engineers select from crossflow, counterflow, staggered flow, or mixed flow arrangements based on the specific needs of the process. The table below summarizes key design features:

Type/Feature | Description |

|---|---|

Plate-Type Air Preheaters | Single-pass forced heat exchange, large surface area, high efficiency |

Modular Design | Facilitates transport and assembly for large-scale applications |

Configurations | Crossflow, counterflow, staggered, or mixed flow options |

Arrangements | Single- and multi-pass available |

Construction | Fully welded, excellent sealing to prevent leakage |

Typical Maintenance Challenges

Operators face several maintenance challenges with plate air preheaters. Ash fouling can clog the heat exchange surfaces, especially when handling ash-laden gases. Acid dew point corrosion may occur in coal-fired plants if metal surfaces cool below 130°C, leading to rapid deterioration. Rotor warping sometimes results from uneven thermal expansion, which can deform internal components. Seal wear can cause leakage, reducing thermal effectiveness and increasing the risk of cross-contamination.

Ash fouling requires frequent cleaning or advanced soot blowing.

Acid dew point corrosion accelerates if surfaces drop below critical temperatures.

Rotor warping may occur due to uneven heating and cooling cycles.

Seal wear demands regular inspection and timely replacement.

Note: Proactive maintenance helps prevent these issues and extends equipment life.

Shanghai Heat Transfer Solutions

Shanghai Heat Transfer addresses these challenges with advanced engineering and expert support. The company uses corrosion-resistant materials and protective coatings to guard against acid dew point corrosion. Fluid treatment systems help prevent fouling and maintain optimal performance. Operator training programs ensure that staff can monitor and maintain the Plate Air Preheater effectively. The table below highlights these strategies:

Maintenance Strategy | Description |

|---|---|

High-grade materials and coatings extend service life | |

Fluid Treatment | Prevents fouling and corrosion, boosts reliability |

Operator Training | Empowers staff to identify and resolve issues quickly |

Shanghai Heat Transfer’s expertise and innovative solutions help industries achieve reliable, efficient, and long-lasting heat recovery.

Cleaning Plate Air Preheater

Mechanical Cleaning

Mechanical cleaning removes solid deposits and ash from the heat exchange surfaces. Operators often use brushes, scrapers, or specialized tools to dislodge stubborn particles. This method works best for dry fouling, such as dust or soot, that accumulates on the plates. Technicians may also use compressed air to blow away loose debris. Mechanical cleaning ensures that the Plate Air Preheater maintains optimal airflow and heat transfer. Shanghai Heat Transfer recommends this approach for routine maintenance, especially in environments with high particulate loads.

Tip: Always inspect the plates for signs of wear or damage after mechanical cleaning.

Chemical Cleaning

Chemical cleaning targets deposits that mechanical methods cannot remove. Operators use approved cleaning agents to dissolve scale, corrosion products, or sticky residues. This process restores the heat transfer efficiency of the Plate Air Preheater. Chemical cleaning works well for industries that process sticky or corrosive gases. Technicians must select chemicals compatible with the plate material to prevent damage. Shanghai Heat Transfer provides guidance on safe chemical selection and application.

Use chemical cleaning when scale or chemical fouling reduces performance.

Always flush the system thoroughly after treatment.

Water Washing

Water washing uses high-pressure water jets to clean the plates. This method removes both loose and some bonded deposits. Operators often use water washing as a quick and effective way to maintain the Plate Air Preheater between major cleanings. It works best for light to moderate fouling. Technicians should avoid excessive water pressure to prevent plate deformation. Water washing also helps reduce downtime, as it can be performed without full disassembly.

Note: Allow the equipment to dry completely before restarting the system.

Anti-Fouling Coatings

Anti-fouling coatings protect the heat exchange surfaces from deposit buildup. These coatings create a smooth barrier that prevents ash, dust, and sticky substances from adhering to the plates. Some Plate Air Preheaters feature self-cleaning mechanisms that use vibration or airflow to dislodge particles automatically. Shanghai Heat Transfer incorporates advanced coatings and design features to minimize fouling and extend cleaning intervals.

Benefit | Description |

|---|---|

Reduced Fouling | Less frequent cleaning required |

Improved Efficiency | Maintains optimal heat transfer |

Longer Service Life | Protects plates from corrosion and wear |

Cleaning Frequency and Safety

Operators should establish a regular cleaning schedule based on operating conditions and fuel type. Most facilities clean the Plate Air Preheater every three to six months. High-dust environments may require more frequent attention. Safety remains a top priority during all cleaning activities. Technicians must wear appropriate personal protective equipment, such as gloves, goggles, and masks. Always lock out and tag out the system before starting maintenance. Follow all manufacturer guidelines and consult Shanghai Heat Transfer for specific recommendations.

Alert: Never mix cleaning chemicals or use unauthorized agents, as this can damage the equipment and pose safety risks.

Maintenance Routine

Inspection Checklist

A thorough inspection routine helps operators maintain safe and efficient operation. Shanghai Heat Transfer recommends using a structured checklist to ensure no critical component is overlooked. The following table outlines essential items for regular inspection:

Component | Description |

|---|---|

Sealing System | Accounts for thermal growths and provides effective sealing with minimal maintenance. |

Rotor Drive Unit | Includes speed reducer, main and standby drive motors, and pinion gear for continuous operation. |

Radial Spherical Roller Bearing | Supports radial loads from air and gas flows, lubricated by an oil bath for longevity. |

Multi-Media Cleaner | Used for on-line soot blowing to control deposit build-up on heat transfer surfaces. |

Thermocouple Temperature Monitor | Monitors air temperature leaving the preheater and alerts operators to high temperatures. |

Leakage Control System | Adjusts sector plates to minimize air-to-gas leakage during operation. |

Deluge Pipes | Used in fire suppression systems to extinguish fires on heat transfer surfaces. |

Tip: Operators should document inspection results and schedule follow-up actions for any issues found.

Gasket and Component Checks

Gaskets play a vital role in preventing leaks and maintaining system integrity. Operators must inspect gaskets for signs of wear, cracking, or deformation. Damaged gaskets can lead to air or gas leakage, reducing efficiency and increasing safety risks. Technicians should also check other components, such as bearings, seals, and drive units, for proper alignment and lubrication. Replacing worn parts promptly ensures reliable operation and extends the lifespan of the equipment.

Inspect gaskets during every scheduled maintenance.

Replace any gasket showing signs of deterioration.

Examine bearings and seals for proper lubrication and alignment.

Confirm that drive units operate smoothly without unusual noise.

Corrosion Prevention

Corrosion can compromise the performance and safety of the Plate Air Preheater. Shanghai Heat Transfer uses corrosion-resistant materials, but operators must still follow best practices to prevent damage. Effective strategies include:

Maintain appropriate temperatures to avoid condensation of corrosive acids.

Control flue gas exit temperatures to mitigate cold-end corrosion.

Operators should monitor temperature readings and adjust system settings as needed. Regular cleaning and inspection help identify early signs of corrosion, allowing for timely intervention.

Operator Training

Well-trained operators contribute to safe and efficient maintenance. Shanghai Heat Transfer offers training programs that teach staff how to recognize common issues, perform inspections, and carry out routine cleaning. Operators learn to use diagnostic tools, interpret temperature data, and follow safety protocols. Continuous education ensures that staff stay updated on the latest maintenance techniques and safety standards.

Alert: Only trained personnel should perform maintenance tasks to reduce the risk of accidents and equipment damage.

Shanghai Heat Transfer Recommendations

Shanghai Heat Transfer advises facilities to establish a proactive maintenance schedule. Regular inspections, prompt component replacement, and ongoing operator training form the foundation of reliable operation. The company recommends documenting all maintenance activities and reviewing performance data to identify trends. By following these guidelines, operators can maximize efficiency, minimize downtime, and extend the service life of the Plate Air Preheater.

Troubleshooting and Support

Performance Issues

Operators may notice a drop in heat recovery or increased fuel consumption. These symptoms often signal reduced heat transfer efficiency. Technicians should check for temperature imbalances and pressure drops. Monitoring system data helps identify problems early. Shanghai Heat Transfer recommends regular process monitoring to maintain optimal performance.

Tip: Consistent performance checks help prevent unexpected downtime and maintain energy savings.

Fouling and Blockages

Fouling and blockages can restrict airflow and lower efficiency. Several factors contribute to these issues:

Low wall shear stress

Low fluid velocities

High fluid velocities

Reaction product solid precipitation

Precipitation of dissolved impurities due to elevated wall temperatures

Technicians should inspect the heat exchange surfaces for deposits. Cleaning methods such as mechanical brushing or water washing can restore normal operation. Regular cleaning schedules reduce the risk of severe blockages.

Leak Detection

Leaks can compromise safety and efficiency. Operators use several methods to detect leaks:

Visual inspection for drips, stains, or wet spots along the frame

Process monitoring for pressure drops, temperature changes, or fluid contamination

Pressure and hydrostatic testing with water, nitrogen, and soap solution

Plate inspection after dismantling to check for pinholes, cracks, or thinning

Gasket and tightening checks to verify bolt torque and replace damaged gaskets

A systematic approach ensures accurate leak detection and timely repairs.

When to Call Shanghai Heat Transfer

Operators should contact Shanghai Heat Transfer when they observe a decline in heat transfer efficiency. Professional support is essential for complex troubleshooting and repairs. Establishing a systematic maintenance regime, including expert services, maximizes the long-term value of the Plate Air Preheater. Regular professional maintenance ensures reliable operation and extends equipment life.

Note: Early intervention by Shanghai Heat Transfer specialists prevents costly failures and supports continuous improvement.

Effective care for the Plate Air Preheater involves several important steps:

Regular inspections help detect leaks, corrosion, and blockages early.

Routine cleaning keeps heat transfer surfaces efficient.

Performance monitoring ensures smooth operation and quick issue detection.

Consistent upkeep reduces fuel use, lowers costs, and supports sustainability. Shanghai Heat Transfer provides expert guidance, advanced support, and training to help operators maintain reliable, efficient systems for years to come.

FAQ

How often should operators clean the Plate Air Preheater?

Operators should clean the Plate Air Preheater every three to six months. Facilities with high dust or ash loads may require more frequent cleaning. Shanghai Heat Transfer recommends following a schedule based on operating conditions.

What safety precautions must technicians follow during maintenance?

Technicians must wear gloves, goggles, and masks. They should lock out and tag out the system before starting work. Shanghai Heat Transfer advises using only approved cleaning agents and following manufacturer guidelines.

Can Shanghai Heat Transfer provide training for maintenance staff?

Shanghai Heat Transfer offers operator training programs. These programs teach staff how to inspect, clean, and maintain Plate Air Preheaters. Training improves safety and ensures reliable operation.

What signs indicate a need for gasket replacement?

Operators should look for cracks, deformation, or leaks around gasket areas. Unusual noises or pressure drops may also signal gasket wear. Immediate replacement prevents efficiency loss and safety risks.