5 key roles of plate heat exchanger gaskets.

Plate heat exchanger gaskets perform 5 key roles: ...

More

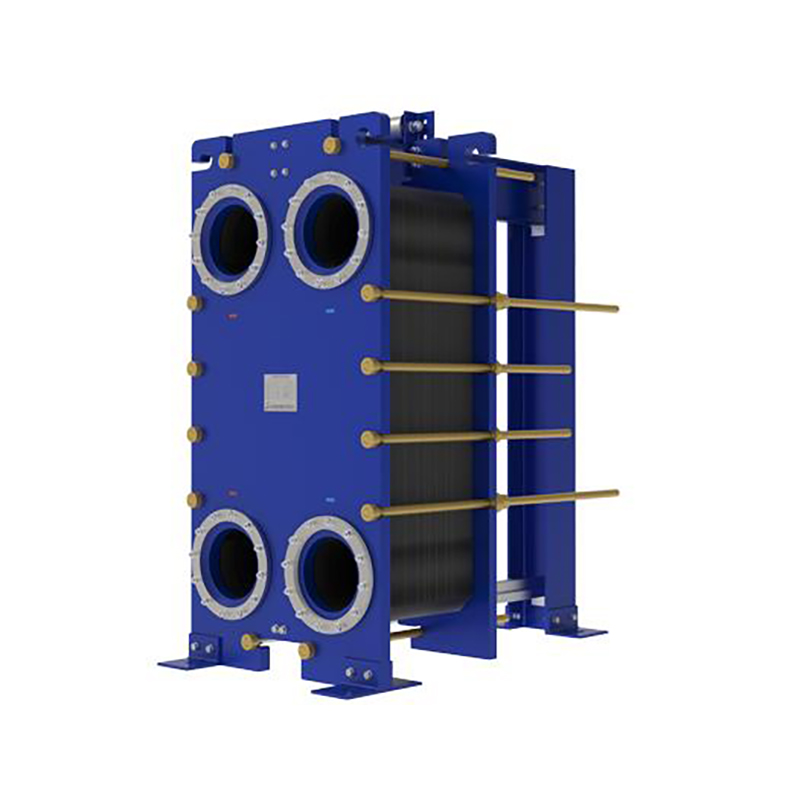

A Flue Gas Cooler (FGC) is a heat exchanger specifically designed to lower the temperature of exhaust gases from industrial processes before they are released into the atmosphere or directed to further treatment systems. Its core principle is based on efficient heat transfer, where thermal energy from the hot flue gas is captured and transferred to a cooler medium, typically water or air. This process not only recovers valuable energy that would otherwise be wasted but also conditions the gas stream for downstream equipment. By precisely controlling the temperature drop, these systems facilitate the condensation of moisture and, in certain applications, the separation of corrosive elements or particulate matter. The design is engineered to handle high temperatures and the often corrosive nature of flue gases, utilizing materials like stainless steel and advanced coatings to ensure longevity and reliable operation. This fundamental process of targeted cooling is the first critical step in enhancing overall system efficiency, reducing the environmental footprint, and protecting downstream capital investments.

The operational principle of a flue gas cooler is a meticulous exercise in thermodynamics and fluid dynamics. Hot exhaust gases, which can range from 150°C to over 500°C depending on the application (e.g., boilers, gas turbines, incinerators, chemical processes), enter the cooler. As they pass through a series of tubes or a specially designed chamber, their heat is absorbed by a cooling medium circulating on the opposite side. In a water-cooled shell and tube design, the water gains thermal energy, which can be repurposed for feedwater pre-heating, district heating, or other industrial processes, directly improving the plant's thermal efficiency. This heat recovery can lead to documented fuel savings of 5-10% in many boiler applications. The cooling process also induces a phase change; as the gas temperature drops below its dew point (often between 45°C and 60°C for many fuels), water vapor condenses. This condensation releases the latent heat of vaporization, which represents a significant portion of the total recoverable energy, further enhancing the system's efficiency. The condensed water also captures a portion of water-soluble pollutants like sulfur oxides (SOx) and particulate matter, initiating a preliminary cleaning of the gas stream. The design must carefully manage the low-temperature corrosion potential by maintaining wall temperatures above the acid dew point or using corrosion-resistant alloys to protect the unit's integrity.

Implementing a flue gas cooler delivers substantial and multi-faceted benefits that directly impact operational profitability, environmental compliance, and system longevity. The primary driver is significant energy recovery; by capturing waste heat, plants drastically reduce fuel consumption required to generate steam or hot water. This translates to lower operating costs and a rapid return on investment (ROI), often within 1-3 years based on energy prices. For instance, in a natural gas-fired boiler system, reducing flue gas temperature from 250°C to 80°C can improve boiler efficiency by approximately 10%. Furthermore, cooling the gases is a prerequisite for the effective operation of many downstream pollution control devices. Baghouses and electrostatic precipitators (ESPs) operate optimally at lower temperatures to protect their filter elements, while wet scrubbers and flue gas desulfurization (FGD) systems require cooled gas to maximize absorption efficiency and minimize water consumption. The process also results in a notable reduction in the volumetric flow rate of the exhaust, allowing for smaller, more cost-effective induced draft (ID) fans and pollution control equipment. From an environmental standpoint, the condensation process reduces particulate emissions (PM2.5/PM10) and facilitates the removal of acid gases, helping facilities meet increasingly stringent air quality regulations. Additionally, by lowering the final exhaust temperature, the visible water vapor plume is significantly minimized or eliminated, addressing community concerns about aesthetic impact.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Plate heat exchanger gaskets perform 5 key roles: ...

More

A gasket in heat exchanger seals surfaces, blocks ...

More

You can see clear differences between welded block...

More

Shanghai Heat Transfer stands out with its ISO9001...

More

Gas to gas plate heat exchangers transfer heat usi...

More

Proper gasket installation in a gasket heat exchan...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

Michael Chen

Maintenance EngineerThis flue gas cooler has been incredibly reliable. It's drastically improved our heat recovery efficiency and the build quality is outstanding. A great investment for our plant.

Sarah Johnson

Plant ManagerInstallation was straightforward and the unit performs exactly as advertised. It has significantly reduced the temperature of our exhaust gases. Very pleased with the performance so far.

David Rodriguez

Process EngineerThe corrosion-resistant materials used in this cooler are top-notch. It has handled our harsh operating conditions without any issues for over a year, saving us on maintenance costs.

Emily Williams

Sustainability OfficerThis cooler has been instrumental in helping us meet our environmental targets by allowing for more efficient downstream scrubbing. The energy savings have also been substantial.