How do gaskets prevent leaks in heat exchangers

A gasket in heat exchanger seals surfaces, blocks ...

More

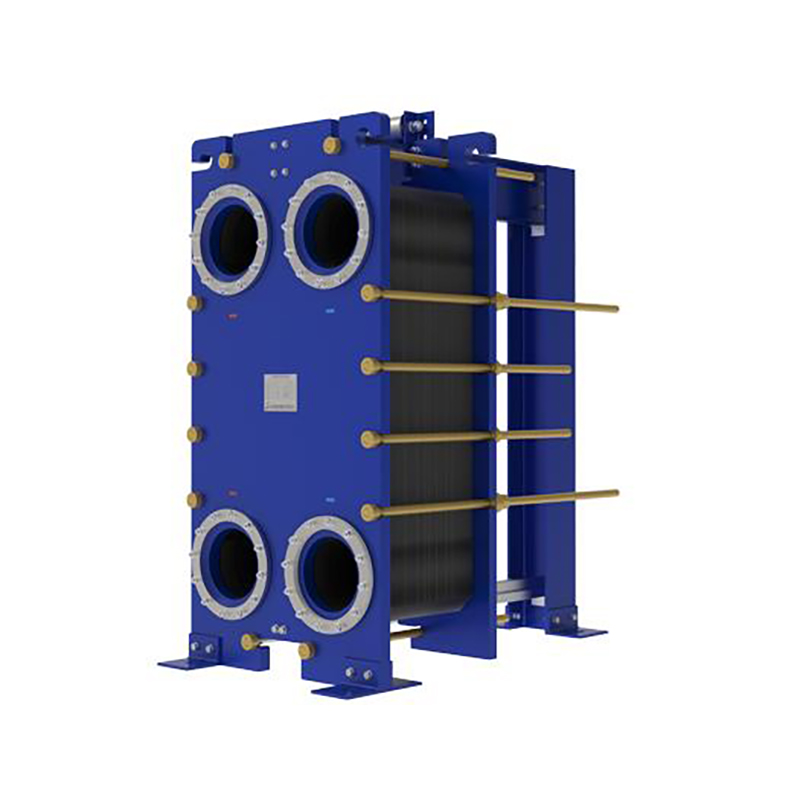

A fluid heat exchanger is a device designed to transfer heat between two or more fluids without mixing them. These systems are widely used in industries such as chemical processing, power generation, HVAC, and automotive to regulate temperatures, improve energy efficiency, and reduce operational costs. Fluid heat exchangers come in various types, including shell-and-tube, plate, and finned-tube designs, each tailored for specific applications. By leveraging advanced materials like stainless steel, titanium, or copper, these exchangers ensure durability and optimal thermal performance.

Fluid heat exchangers operate on the principles of conduction and convection, enabling efficient heat transfer between liquids, gases, or a combination of both. For instance, in a shell-and-tube exchanger, one fluid flows through tubes while another circulates around them in a shell, facilitating heat exchange. Plate heat exchangers, on the other hand, use corrugated plates to maximize surface area and enhance thermal transfer. According to industry data, modern fluid heat exchangers can achieve thermal efficiencies exceeding 90%, making them indispensable for energy-intensive processes. Their applications range from cooling industrial machinery to recovering waste heat in power plants, significantly reducing energy consumption and carbon emissions.

Fluid heat exchangers offer unparalleled advantages in terms of energy savings, operational reliability, and environmental sustainability. Industries worldwide rely on these systems to optimize thermal management, cut costs, and comply with stringent environmental regulations. With their ability to handle high pressures and temperatures, fluid heat exchangers are ideal for demanding environments such as oil refineries, chemical plants, and renewable energy facilities.

Choosing a fluid heat exchanger ensures long-term performance and reduced maintenance costs. For example, plate heat exchangers are known for their compact design and easy scalability, while shell-and-tube models excel in high-pressure applications. Data from market research indicates that businesses using fluid heat exchangers can reduce energy consumption by up to 40%, translating to significant cost savings. Additionally, advancements in materials and design, such as additive manufacturing and nano-coated surfaces, have further enhanced their efficiency and lifespan. By investing in a high-quality fluid heat exchanger, companies can achieve sustainable operations, lower their carbon footprint, and gain a competitive edge in their respective industries.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

A gasket in heat exchanger seals surfaces, blocks ...

MoreAPI 662 defines standards for plate heat exchanger...

More

Ignoring a fouled heat exchanger causes high energ...

More

A heat exchanger's main parts include the heat tra...

More

Plate heat exchangers deliver high thermal efficie...

More

Gasketed plate heat exchangers boost industrial ef...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

John Smith

Mechanical EngineerThe fluid heat exchanger performs exceptionally well under high-pressure conditions. It's a game-changer for our industrial applications.

Emily Johnson

HVAC TechnicianThis heat exchanger is energy-efficient and easy to install. Perfect for commercial HVAC systems.

Michael Brown

Process EngineerReliable and durable. The fluid heat exchanger has significantly improved our plant's thermal efficiency.

Sarah Davis

Energy ConsultantGreat product for renewable energy systems. The compact design saves space without compromising performance.