Gasketed Plate Heat Exchanger Operating Principles

Gasketed Plate Heat Exchanger Operating Principles

Maximizing Heat Transfer Efficiency

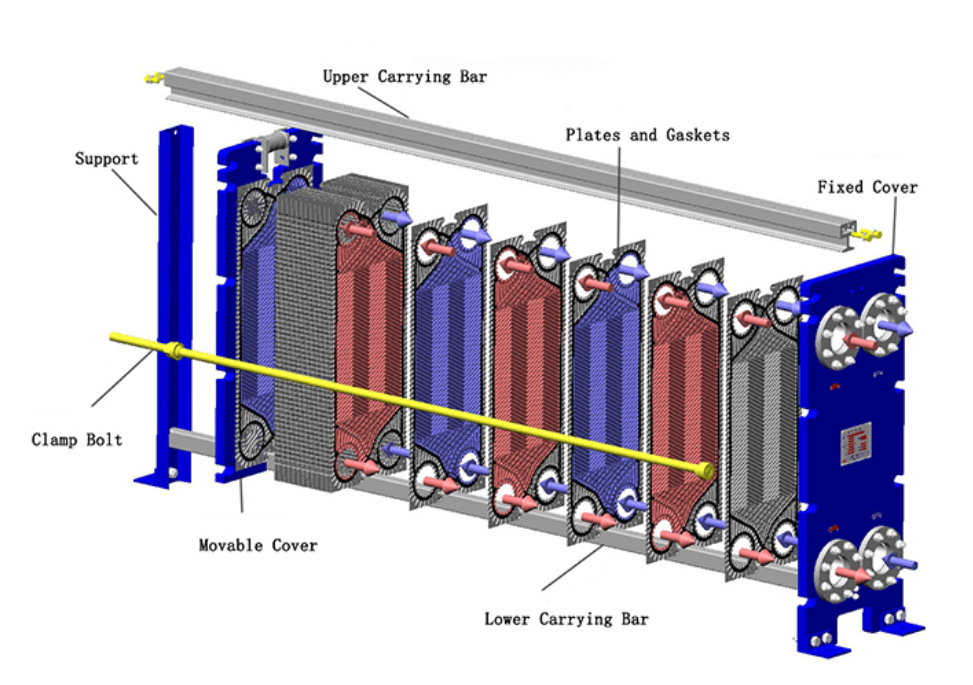

A gasketed plate heat exchanger operates by channeling fluids between thin, corrugated plates. This design increases the surface area available for heat exchange, which boosts thermal performance. Researchers have observed that the compact structure and enhanced heat transfer area outperform traditional heat exchangers in industrial environments.

·Experimental data shows that inlet and outlet temperature differences confirm the exchanger’s effectiveness.

·Studies highlight the importance of maintaining clean plates to achieve optimal heat transfer rates and coefficients.

·Hydraulic cooling systems benefit from high convective heat transfer coefficients, as demonstrated in recent research.

·Thermodynamic analyses reveal that counter-current flow configurations deliver superior energy and exergy efficiencies.

Preventing Fluid Mixing and Fouling

The gasket arrangement on each plate creates two separate channels, allowing primary and secondary fluids to flow in a counter-current manner without mixing. High-performance gaskets seal the plates, preventing leaks and cross-contamination.

| Feature | Benefit |

|---|---|

| Separate channel systems | No fluid mixing between streams |

| Reliable gasket seals | Prevents leakage and contamination |

| Minimal fouling | Reduces stress, wear, and corrosion |

Industrial users rely on gasketed plate heat exchangers for their ability to maintain fluid purity and minimize fouling. These features ensure consistent operation and reduce maintenance needs over time.

Sustained Energy Efficiency with Gasketed Plate Heat Exchanger

Large Heat Transfer Surface Area

Engineers select gasketed plate heat exchangers for their ability to deliver high thermal performance in industrial environments. The thin, corrugated plates inside each unit create a large surface area for heat transfer. This design maximizes contact between hot and cold fluids, which speeds up temperature exchange and improves overall efficiency.

·The unique plate patterns generate turbulence, increasing the heat transfer coefficient.

·Plate heat exchangers offer a large heat transfer surface area per unit volume, making them suitable for facilities with limited space.

·The alternating arrangement of hot and cold fluid streams enhances thermal-hydraulic performance.

Industrial managers often notice lower capital costs because the efficient design requires less surface area to achieve the same results as bulkier systems. The large heat transfer surface area also supports faster response times during temperature changes, which helps maintain stable operations.

Elimination of Stagnant Zones

Gasketed plate heat exchangers feature optimized flow patterns that prevent the formation of stagnant zones. The plates guide fluids through narrow channels, ensuring continuous movement and uniform distribution. This approach eliminates areas where fluids might slow down or stop, which can cause inefficiency and fouling.

Operators value this design because it keeps heat transfer rates consistent over time. The absence of stagnant zones means that the exchanger maintains high performance, even after years of operation. The steady flow also reduces the risk of deposits and corrosion, which extends equipment life and minimizes maintenance needs.

·Thin plates and engineered flow paths ensure maximum surface contact between fluids.

·High turbidity inside the channels promotes turbulence, which prevents buildup and supports sustained energy efficiency.

Industrial facilities that implement gasketed plate heat exchangers often observe long-term improvements in energy efficiency. The reduction in energy consumption translates directly into lower utility bills and ongoing cost savings.

Ongoing Cost Savings from Gasketed Plate Heat Exchanger

Lower Utility Bills

Industrial facilities experience significant reductions in utility bills when they implement a gasketed plate heat exchanger. The advanced design allows for efficient heat transfer, which minimizes energy consumption. Facilities using variable flow systems avoid higher pump running costs, while fixed flow systems benefit from lower chiller evaporation temperatures. Waste heat recovery further reduces natural gas heating expenses. The following table highlights annual savings and carbon dioxide reductions for different system types:

| System Type | Savings Description | Annual Savings (€) | CO2 Savings (kg) |

|---|---|---|---|

| Variable Flow | Avoid higher pump running costs | 5,265 | 26,200 |

| Fixed Flow | Avoid lower chiller evaporation temperature | 18,290 | 91,980 |

| Chiller Off (360h) | Utilising cool ambient temperature from open cooling tower | 42,048 | 210,240 |

| Waste Heat Recovery | Save on natural gas heating costs for tap water | 21,600 | 216,000 |

Facilities that choose gasketed plate heat exchangers report lower energy bills and reduced carbon emissions year after year.

Reduced Operating Expenses

Operating expenses decrease over time due to the precision and reliability of gasketed plate heat exchangers. These units deliver improved temperature control and true counter-current flow, which results in less hold-up volume—up to 80-90% less than traditional systems. The following table outlines key advantages:

| Advantage | Description |

|---|---|

| Exceptional heat transfer precision | Improved temperature approach, true counter-current flow, and significantly less hold-up volume |

| Economically sound choice | Low capital investment, installation costs, and limited maintenance and operating costs |

| Highly reliable with minimal fouling | Reduced maintenance and operating costs due to minimal fouling |

Lifecycle cost analyses show that, although initial investment costs may be higher, gasketed plate heat exchangers provide improved energy efficiency and lower operational costs over their lifespan. Maintenance requirements remain low, which further reduces expenses for industrial users.

Durability and Reliability of Gasketed Plate Heat Exchanger

Robust Construction for Industrial Demands

Engineers design gasketed plate heat exchangers to withstand tough industrial environments. Manufacturers select robust materials and use safe production techniques to ensure each unit meets high standards. These heat exchangers feature durable designs that resist wear and corrosion. High thermal conductivity materials boost heat transfer efficiency, while strong gasket designs improve sealing and extend service life.

·Durable designs rely on robust materials.

·Safe manufacturing processes guarantee reliability.

·High thermal conductivity materials enhance efficiency.

·Robust gasket designs increase sealing performance and longevity.

The dual-seal structure and honeycomb-like gasket locking system play key roles in durability. These features reduce sliding distance and lock the gasket securely, which improves sealing and prevents leaks.

| Feature | Contribution to Durability |

|---|---|

| Dual-seal structure | Reduces sliding distance of the gasket, enhancing sealing. |

| Honeycomb-like structure | Locks the gasket securely, improving sealing performance. |

Manufacturers emphasize durability in every step, so the final product can handle demanding industrial conditions.

Consistent Performance Over Time

Industrial users value consistent performance from their heat exchangers. The gasketed plate heat exchanger delivers reliable operation year after year. Facilities report lower operating and maintenance costs, along with reduced risk of breakdowns. Predictive maintenance helps control budgets and keeps systems running smoothly.

| Audit Advantages | Description |

|---|---|

| Reduce Costs | Lower operating, maintenance, and parts inventory costs over the long term. |

| Eliminate Breakdown Risk | Virtually eliminate the risk of breakdown due to component failure. |

| Predictive Maintenance | Control your maintenance budget with predictive maintenance. |

| Increase Efficiency | Increase production efficiency and profitability. |

Industry trends show continued growth in demand for energy-efficient systems. Technological advancements lead to more compact and durable designs. Automation and IoT-enabled monitoring further extend the lifespan and reliability of these units.

Ease of Maintenance for Gasketed Plate Heat Exchanger

Simple Cleaning and Inspection

Industrial operators appreciate the straightforward cleaning process of a gasketed plate heat exchanger. The modular design allows technicians to open the unit quickly, providing direct access to the plates for inspection and cleaning. This approach reduces the risk of fouling, which can lower efficiency if left unchecked. Regular cleaning prevents buildup and maintains optimal heat transfer rates.

Maintenance schedules often include monthly leak checks, quarterly cleaning, and annual deep inspections. The following table outlines recommended maintenance intervals and their purposes:

| Maintenance Frequency | Description | Purpose |

|---|---|---|

| Monthly | Check for leaks and pressure drops | Early detection of issues |

| Quarterly | Clean and inspect for buildup | Prevent fouling and maintain efficiency |

| Annually | Non-destructive testing and deep cleaning | Ensure long-term reliability |

Technicians can replace gaskets without welding, which simplifies the process and reduces labor costs. Early detection of fouling helps avoid extended downtime and expensive repairs.

Regular maintenance keeps the heat exchanger running efficiently and extends its service life.

Minimal Downtime and Quick Plate Replacement

Facilities benefit from minimal downtime when servicing a gasketed plate heat exchanger. Skilled technicians respond promptly to malfunctions, using genuine spare parts to optimize performance. The modular design enables fast plate replacement and upgrades, minimizing operational disruptions.

·Expert maintenance services ensure peak efficiency.

·Predictive maintenance strategies help reduce downtime and improve production.

·Flexible servicing options allow for on-site or off-site repairs.

Advanced leakage detection systems support efficient audits without disassembly. Quick on-site inspections provide immediate results, allowing operators to identify necessary actions and maintain a competitive edge.

| Feature | Description |

|---|---|

| Minimized downtime | Quick access to critical components for fast replacement |

| Comprehensive plate cleaning | Ensures optimal performance and longevity |

| Fast test process | Rapid inspections to minimize operational delays |

Facilities that prioritize regular maintenance and rapid servicing maintain high efficiency and reliability over the long term.

Adaptability of Gasketed Plate Heat Exchanger in Industrial Applications

Modular Design and Scalability

Engineers value the modular design of these heat exchangers. This structure allows for quick disassembly, making cleaning and repairs straightforward. Operators can add, remove, or rearrange plates to match changing process requirements. A single unit can hold up to 700 plates, which supports significant capacity adjustments. This flexibility helps facilities respond to shifts in production volume or process changes without replacing the entire system.

·Quick disassembly for easy maintenance

·Plates added or removed for capacity changes

·Up to 700 plates per exchanger for large-scale operations

The modular approach also supports a wide range of industries. Facilities in HVAC, food and beverage, and chemical processing all benefit from this adaptability. Each sector can optimize heat transfer and maintain high efficiency by adjusting the configuration as needed.

Upgrades for Evolving Needs

Industrial processes often change over time. The gasketed plate heat exchanger adapts easily to new requirements. Technicians can upgrade the system by adding more plates or changing the plate arrangement. Elastomeric gaskets provide reliable sealing and direct fluid channels, which makes modifications simple.

·Easy cleaning and modification by adding or removing plates

·Corrugated plates enhance heat transfer efficiency

·Supports hygiene and product quality in sensitive industries

This adaptability ensures that the heat exchanger remains effective as technology advances or as regulations shift. Facilities can maintain high performance and meet new standards without major investments.

Environmental Impact of Gasketed Plate Heat Exchanger

Reduced Carbon Footprint

Industrial facilities face growing pressure to lower their environmental impact. A gasketed plate heat exchanger helps companies achieve this goal by optimizing heat transfer and reducing energy input. Many industries, including HVAC, food and beverage, chemical, and power generation, choose these systems for their high efficiency and compact design.

·Lower heat loss means less wasted energy.

·Improved energy efficiency leads to smaller environmental footprints.

·Facilities report consistent reductions in energy consumption over time.

Operators see direct benefits from these features. They use less fuel and electricity, which results in fewer greenhouse gas emissions. The compact structure also allows for easier integration into existing systems, further supporting sustainability goals.

Support for Sustainable Operations

Gasketed plate heat exchangers play a key role in sustainable industrial practices. Companies that replace older heat exchangers with modern units often see dramatic improvements.

Refineries have removed 41% more heat from processes without expanding their installation footprint.

Higher energy efficiency and easier maintenance reduce total cost of ownership.

Facilities have saved valuable resources, such as 8.5 tonnes of titanium, by using more efficient designs.

Seawater consumption has dropped by 16% per kilowatt-hour of heat removed.

Food and beverage processors rely on these exchangers for efficient thermal transfer. The large surface area and specialized gaskets create separate channels for fluids, which boosts operational efficiency and supports sustainable production.

Operators who invest in modern heat exchangers contribute to resource conservation and long-term environmental protection.

Industrial users recognize the gasketed plate heat exchanger for its strong lifecycle ROI, modularity, and high thermal efficiency.

·Global demand continues to rise, driven by energy savings and versatility across industries.

·Decision-makers should assess pressure tolerance, maintenance needs, and application requirements before selection.

| Challenge | Solution |

|---|---|

| Fouling | Advanced cleaning techniques |

| Corrosion | Protective coatings |

FAQ

What industries benefit most from gasketed plate heat exchangers?

Food processing, chemical manufacturing, HVAC, and power generation industries see the greatest benefits. These sectors require efficient heat transfer and reliable, adaptable equipment.

How often should facilities inspect gasketed plate heat exchangers?

Facilities should inspect these units monthly for leaks and quarterly for buildup. Regular checks help maintain efficiency and prevent unexpected downtime.

Can gasketed plate heat exchangers handle corrosive fluids?

Yes. Manufacturers offer models with corrosion-resistant plates and gaskets. These units safely process aggressive chemicals and extend equipment lifespan.