Comparing welded block and gasketed plate heat exchangers

You can see clear differences between welded block...

More

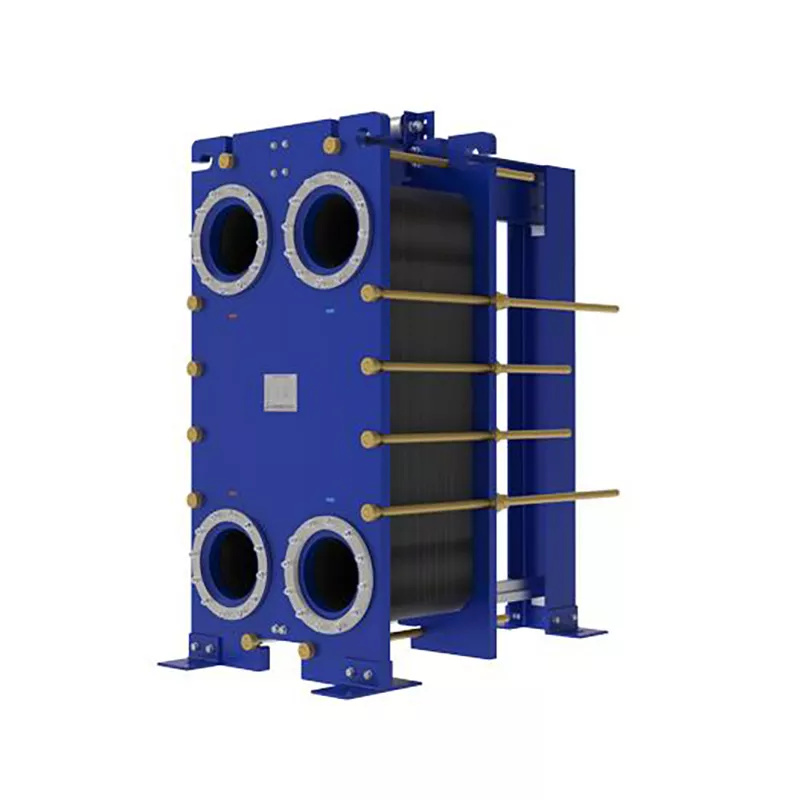

The fundamental principle of a gasketed plate heat exchanger (PHE) revolves around transferring heat between two fluids through a series of thin, corrugated metal plates sealed with gaskets. These plates are assembled in a frame, creating alternating channels for the hot and cold media to flow through. The strategically designed plate corrugations, often in a chevron pattern, induce turbulent flow at relatively low velocities. This turbulence is critical as it minimizes the formation of a stagnant boundary layer on the plate surfaces, significantly enhancing the heat transfer coefficient compared to simpler shell and tube designs. The large surface area provided by the compact plate pack, combined with this forced turbulence, allows for extremely efficient thermal exchange. The gaskets perform the dual function of sealing the fluids within their designated channels and preventing them from mixing, while also allowing for relative ease of access for maintenance, cleaning, and capacity adjustment by simply adding or removing plates. This design is the cornerstone of its exceptional performance in a wide array of heating, cooling, and heat recovery duties across industries.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

You can see clear differences between welded block...

More

API 662 defines standards for plate heat exchanger...

More

A gasket in heat exchanger seals surfaces, blocks ...

More

Plate heat exchanger gaskets perform 5 key roles: ...

More

GPHE heat exchangers are vital in food, HVAC, chem...

More

Compare top frame plate heat exchanger models for ...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

David Chen

Maintenance EngineerThe gasketed plate heat exchanger performed exceptionally well in our HVAC system. Installation was straightforward and it has significantly improved our heat transfer efficiency with zero leaks since commissioning.

Sarah Johnson

Process TechnicianOutstanding durability and performance! These gasketed plates have handled our high-temperature dairy processing for over 12 months without any degradation. Easy to maintain and clean for our hygiene standards.

Michael Rodriguez

Plant ManagerReliable and efficient heat transfer solution for our chemical mixing processes. The gasket design provides excellent sealing and the plates are corrosion resistant. Would recommend for industrial applications.

Emily Watson

Facility EngineerPerfect solution for our district heating system. The modular design allows easy capacity expansion, and the gasketed plates maintain perfect temperature control even under fluctuating demand conditions. Exceptional quality.