How do gaskets prevent leaks in heat exchangers

A gasket in heat exchanger seals surfaces, blocks ...

More

A Hastelloy heat exchanger is a specialized thermal transfer device constructed from Hastelloy alloys, a family of nickel-based superalloys renowned for their exceptional resistance to corrosion, oxidation, and high-temperature degradation. These heat exchangers are engineered to handle aggressive chemical environments, including sulfuric acid, hydrochloric acid, and chloride-rich solutions, where conventional materials like stainless steel fail. Hastelloy heat exchangers are widely used in industries such as chemical processing, oil and gas, pharmaceuticals, and power generation, where reliability and longevity are critical. Their ability to maintain structural integrity under extreme conditions makes them indispensable for critical applications.

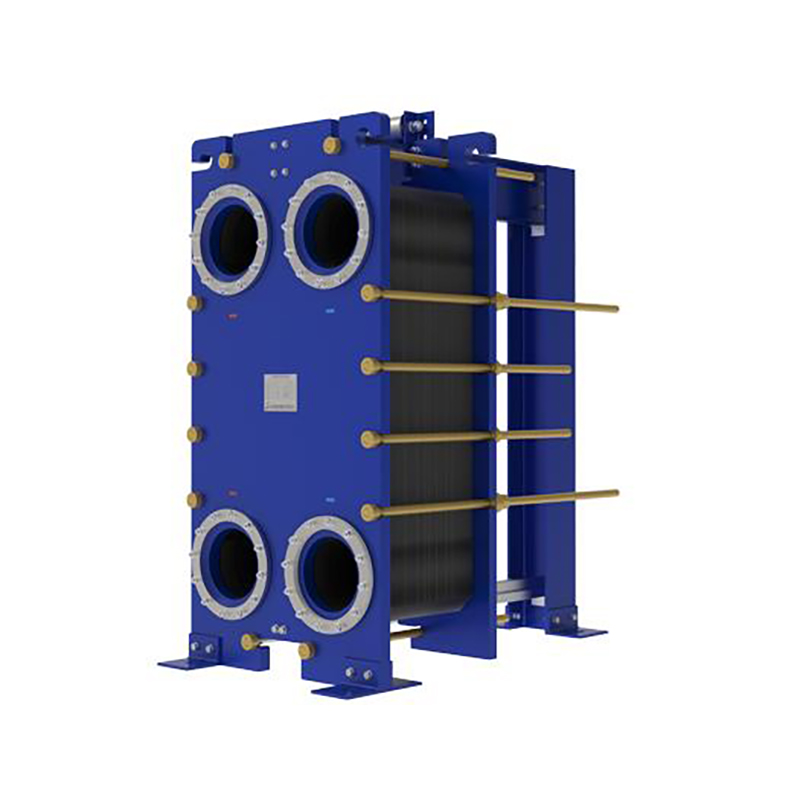

Hastelloy heat exchangers leverage the unique properties of alloys like Hastelloy C-276, C-22, and B-2, which offer superior performance in both reducing and oxidizing environments. These alloys are meticulously designed to resist pitting, crevice corrosion, and stress corrosion cracking, ensuring uninterrupted operation even in the harshest conditions. The heat exchangers are available in various configurations, including shell-and-tube, plate-and-frame, and air-cooled designs, tailored to meet specific industrial requirements. Their versatility and durability make them a preferred choice for engineers seeking long-term solutions in corrosive applications.

The primary advantage of Hastelloy heat exchangers lies in their unmatched corrosion resistance, which significantly extends equipment lifespan and reduces maintenance costs. Unlike standard materials, Hastelloy alloys can withstand prolonged exposure to highly corrosive media, minimizing downtime and operational disruptions. Additionally, these heat exchangers exhibit excellent thermal conductivity and mechanical strength at elevated temperatures, ensuring efficient heat transfer even in extreme conditions. Their resistance to localized corrosion, such as pitting and crevice corrosion, further enhances reliability in critical processes.

Hastelloy heat exchangers also offer economic benefits despite their higher initial cost. Their longevity and reduced need for replacements or repairs translate to lower total cost of ownership over time. Industries report up to 50% longer service life compared to stainless steel alternatives, as evidenced by case studies in chemical plants and refineries. Furthermore, their compatibility with a wide range of chemicals and operating temperatures makes them adaptable to diverse applications. With global demand for corrosion-resistant solutions rising, Hastelloy heat exchangers are increasingly recognized as a cost-effective investment for sustainable industrial operations.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

A gasket in heat exchanger seals surfaces, blocks ...

MoreAPI 662 defines standards for plate heat exchanger...

More

Ignoring a fouled heat exchanger causes high energ...

More

A heat exchanger's main parts include the heat tra...

More

Plate heat exchangers deliver high thermal efficie...

More

Gasketed plate heat exchangers boost industrial ef...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

John Smith

Chemical EngineerThe Hastelloy heat exchanger performs exceptionally well in corrosive environments. It has significantly improved our process efficiency.

Emily Johnson

Maintenance SupervisorDurable and reliable. The Hastelloy heat exchanger requires minimal maintenance and handles high temperatures with ease.

Michael Brown

Plant ManagerExcellent product! The heat exchanger's corrosion resistance is unmatched, making it perfect for our harsh operating conditions.

Sarah Davis

Process EngineerThe Hastelloy heat exchanger delivers consistent performance and has a long lifespan. Highly recommended for demanding applications.