Heat Exchange Solutions for Power Industry

Power industry is essential for modern life, driving economic growth and sustainability through advancements in renewable energy, smart grids, and energy storage. It plays a critical role in reducing carbon emissions and ensuring reliable energy access. Plate heat exchangers are vital in this sector, enhancing energy efficiency by optimizing heat transfer in power plants. Their compact design and high efficiency reduce energy consumption and operational costs, supporting sustainable thermal management. Together, the power industry and plate heat exchangers are key to advancing global energy solutions and achieving a greener future.

Addressing Your Needs with Tailored Solutions

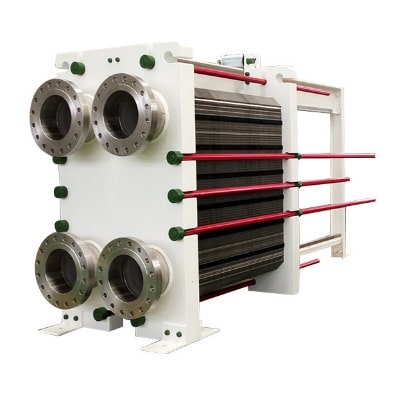

In Power Industry, heat exchangers are prone to faults such as leaks, excessive pressure drops caused by clogging, and reduced efficiency due to fouling. These issues can disrupt system performance and increase maintenance costs. Plate heat exchangers are favored for their high heat transfer efficiency, compact design, and ease of maintenance, making them ideal for optimizing thermal management in power plants. Their corrosion-resistant materials and ability to handle high temperatures and pressures ensure reliable operation in demanding environments.

-

High Heat Transfer Efficiency

Plate heat exchangers must achieve optimal heat transfer rates to enhance energy efficiency in power plants, ensuring minimal energy loss during thermal processes. -

Corrosion Resistance

Materials like Stainless Steel or Titanium alloys are essential to withstand corrosive media in power systems, ensuring durability and long-term performance. -

Compact Design

The exchangers should have a space-saving structure to fit seamlessly into power plant layouts, while maintaining high thermal performance. -

Easy Maintenance

They must be designed for quick disassembly and cleaning to reduce downtime and maintenance costs, ensuring continuous operation.

Your Needs, Our Priority

contact usPractical Applications in Power Industry

-

(1) Thermal Power Generation

Thermal power plants generate electricity by burning fossil fuels such as coal, natural gas, or oil. The process involves fuel combustion in a boiler to produce high-pressure steam, which drives a turbine connected to a generator. The steam is then condensed back into water using condensers and recycled. Plate heat exchangers are widely used in condensers to cool the steam efficiently and in waste heat recovery systems to capture and reuse excess heat, improving overall plant efficiency and reducing energy loss. -

(2) Nuclear Power Generation

Nuclear power plants use nuclear fission to heat water, producing steam that drives turbines. The process includes nuclear reactions in the reactor core, heat transfer to water, steam generation, and electricity production. Plate heat exchangers play a critical role in cooling systems, such as reactor coolant loops and spent fuel pools, ensuring efficient heat transfer and maintaining safe operating temperatures. They are also used in secondary circuits to enhance thermal efficiency. -

(3) Renewable Energy (Solar and Geothermal)

Solar thermal and geothermal plants convert solar or geothermal heat into electricity. Solar plants use mirrors to concentrate sunlight, heating a fluid to produce steam, while geothermal plants extract heat from underground reservoirs. Plate heat exchangers are essential in transferring heat from solar collectors or geothermal fluids to power cycles, enhancing energy conversion efficiency and system performance. They also help manage thermal fluctuations in these systems. -

(4) Supercritical CO₂ Power Generation

Supercritical CO₂ power systems use CO₂ in its supercritical state as a working fluid in a Brayton cycle. The process involves compressing CO₂, heating it to supercritical temperatures, expanding it through a turbine, and recovering heat. Plate heat exchangers are used in recuperators and coolers to manage heat transfer, ensuring compact and efficient system operation. They are particularly effective in handling high-pressure and high-temperature conditions, improving overall cycle efficiency. -

(5) Industrial Waste Heat Recovery

Industries recover waste heat from processes like steel or cement production to generate electricity. The process involves capturing heat from exhaust gases or hot fluids, transferring it to a working fluid, and driving a turbine. Plate heat exchangers are used to transfer heat from industrial waste streams to power cycles, maximizing energy utilization and reducing operational costs. They are also employed in preheating systems to improve overall process efficiency.

Case Examples

Service

Shanghai Heat Transfer Board Replacement Parts Warehouse can provide various original accessories at any time to ensure product quality. At the same time, the Shanghai board can open a spare parts query interface to check inventory or issue spare parts plans anytime and anywhere, ensuring timely delivery.

more details

Who Are We?

Shanghai Heat Transfer Equipment Co., Ltd.(SHPHE) specializes in the design, manufacturing, installation, and service of plate heat exchangers and complete heat transfer systems.

more details

To Provide You with Better Service

Honor Our Common Journey,Develop Authentic Alliances,Create Collective Success.

Leave Your Message

* Full Name

* Country/Region

* Email

* Company name

* Telephone Number

* Enter your needs

SHPHE has complete quality assurance system from design, manufacturing, inspection and delivery. It is certified with ISO9001, ISO14001, OHSAS18001 and hold ASME U Certificate.