5 key roles of plate heat exchanger gaskets.

Plate heat exchanger gaskets perform 5 key roles: ...

More

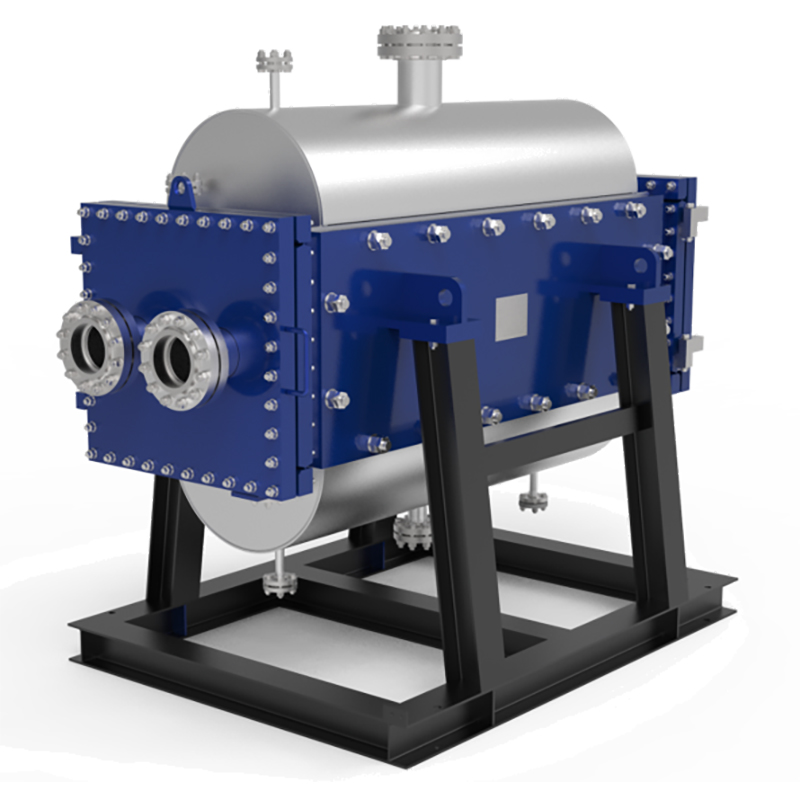

A heat exchanger is a device designed to efficiently transfer heat between two or more fluids without mixing them, widely used in industries like HVAC, power plants, and refrigeration. Heat interchangers, though less commonly referenced, often refer to systems that alternate heat transfer between multiple streams or storage mediums, such as regenerative heat exchangers in industrial processes. While both terms are sometimes used interchangeably, "heat exchanger" is the standard technical term, whereas "heat interchanger" may imply specialized applications like periodic flow reversal or energy recovery systems.

Heat exchangers are critical in energy conservation, with the global market valued at $17.5 billion in 2022 (Grand View Research). Common types include shell-and-tube, plate, and air-cooled exchangers, each suited for specific temperature and pressure conditions. For example, plate heat exchangers achieve over 90% thermal efficiency in compact designs, making them ideal for food processing. In contrast, heat interchangers like rotary regenerators in steel mills recover waste heat at 60–80% efficiency, reducing fuel consumption by 20–30% (U.S. DOE data). Misconceptions arise when "interchanger" describes dual-function systems, but industry standards prioritize "exchanger" for clarity.

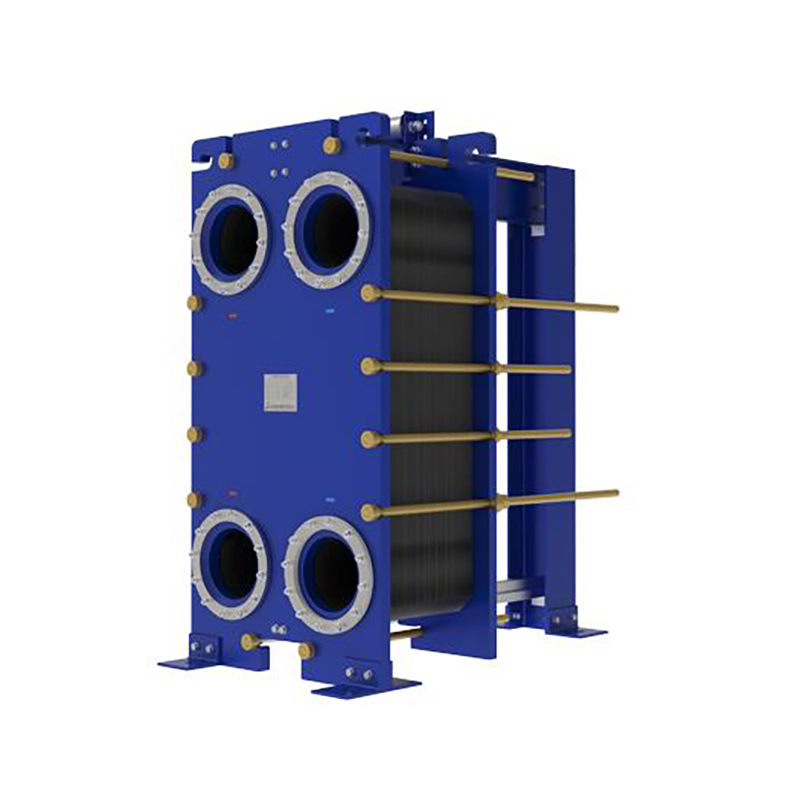

Heat exchangers operate on principles of conduction and convection, where hot and cold fluids flow separately through channels separated by conductive barriers. For instance, in a car radiator, coolant absorbs engine heat and releases it via finned tubes to air. Plate exchangers use corrugated metal plates to maximize surface area, achieving 3–5x higher heat transfer than tubular designs (API Energy reports). Meanwhile, heat interchangers like fixed-bed regenerators alternate hot/cold gas flows through ceramic matrices, storing and releasing thermal energy cyclically—a method proven to cut emissions by 15% in glass manufacturing (European Commission studies).

Advanced designs leverage phase change (e.g., condensers) or turbulence enhancers (e.g., helical baffles) to optimize performance. A 2021 ASHRAE study showed that microchannel heat exchangers reduce refrigerant charge by 50% while maintaining 95% efficiency. Interchangers excel in batch processes; for example, cement plants use gravity-fed heat recovery systems to preheat raw materials, slashing energy use by 25%. Real-world data confirms that proper maintenance—like descaling plates annually—can sustain 90%+ efficiency for over a decade, per HVAC industry benchmarks.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Plate heat exchanger gaskets perform 5 key roles: ...

More

A gasket in heat exchanger seals surfaces, blocks ...

MoreAPI 662 defines standards for plate heat exchanger...

More

You can see clear differences between welded block...

More

Maximize energy efficiency and cut costs by select...

More

A heat exchanger plate is a core component that tr...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

John Smith

Mechanical EngineerThe heat exchanger performs exceptionally well in our industrial setup. It's energy-efficient and has significantly reduced our operational costs.

Emily Johnson

HVAC TechnicianThe heat interchanger is easy to install and maintain. It has improved the efficiency of our heating systems. Highly recommended!

Michael Brown

Process EngineerThis heat exchanger is a game-changer for our chemical processing plant. It handles high temperatures and pressures with ease.

Sarah Davis

Energy ConsultantThe heat interchanger has been a great addition to our renewable energy projects. It's reliable and has a compact design.