5 key roles of plate heat exchanger gaskets.

Plate heat exchanger gaskets perform 5 key roles: ...

More

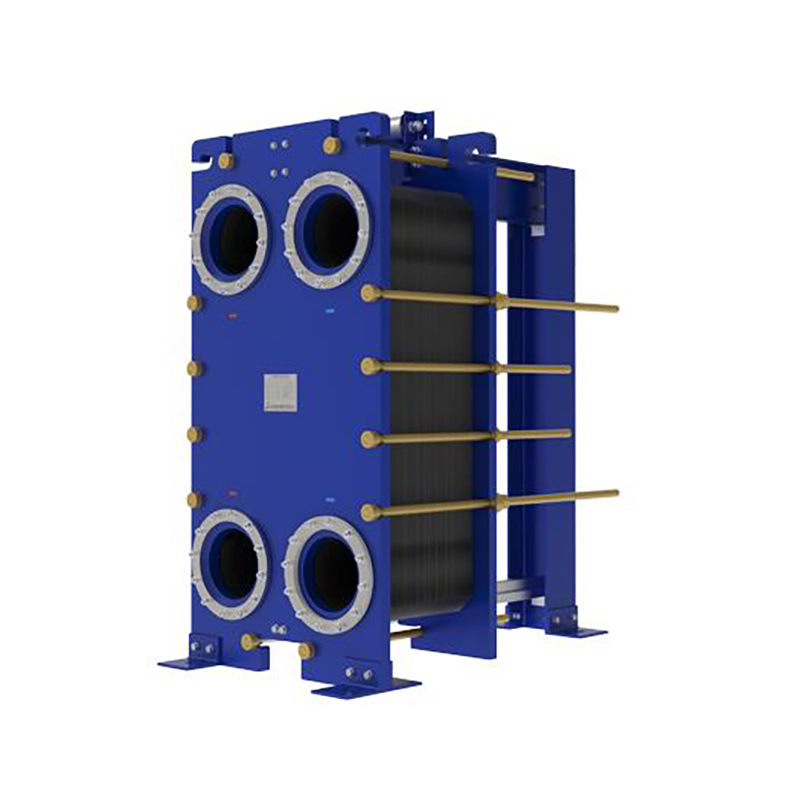

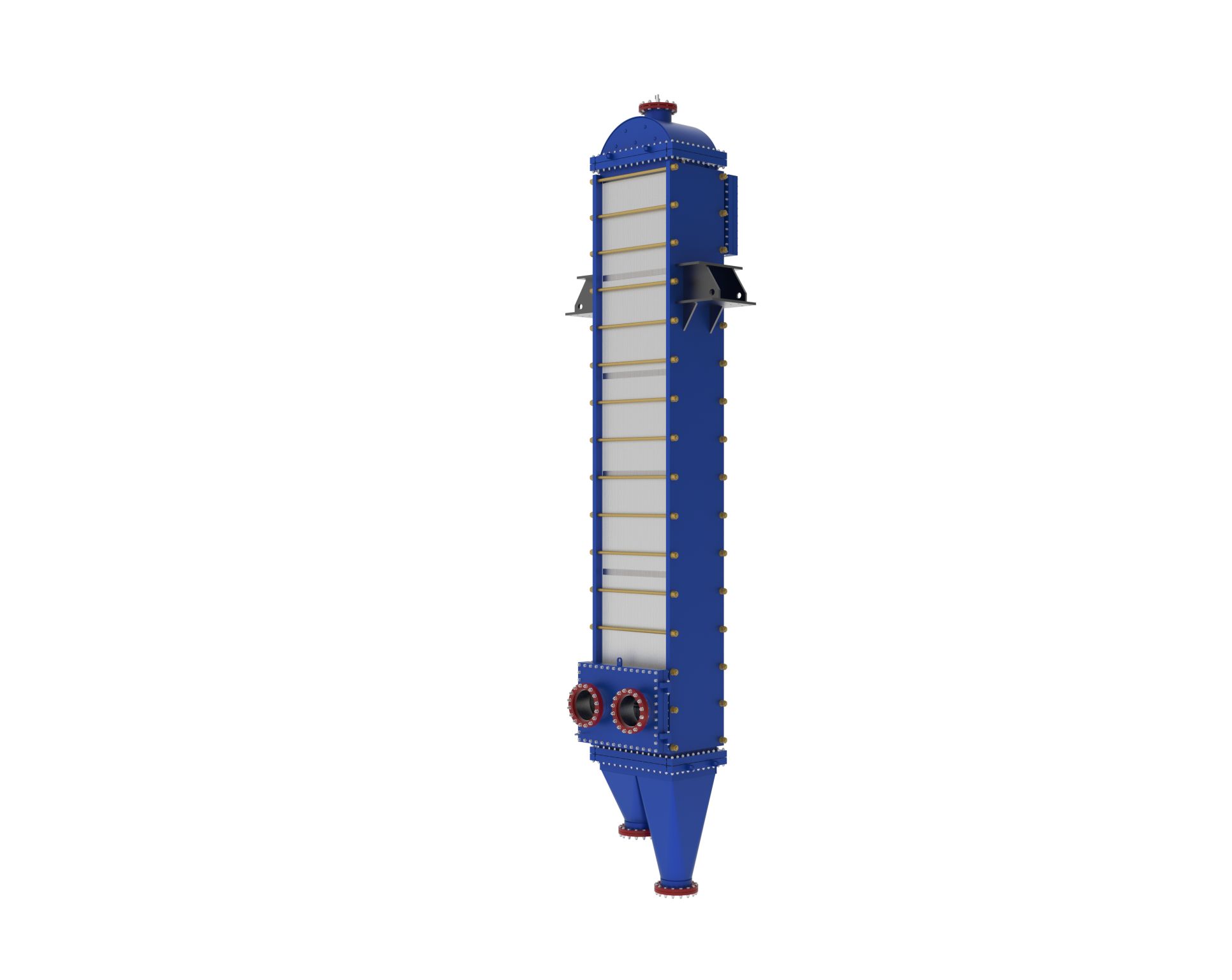

Geothermal power plants harness the Earth's natural heat to generate clean, renewable energy. A heat exchanger plays a critical role in this process by transferring thermal energy from geothermal fluids to a secondary working fluid, typically an organic compound like isobutane or pentane. This enables efficient electricity production while minimizing environmental impact. Without heat exchangers, geothermal plants would struggle to achieve the high thermal efficiency required for cost-effective operation.

According to industry data, geothermal power plants utilizing advanced heat exchangers can achieve thermal efficiencies of up to 20-23%, significantly higher than traditional systems. The U.S. Department of Energy highlights that binary cycle geothermal plants, which rely heavily on heat exchangers, account for nearly 50% of new geothermal installations due to their ability to operate at lower temperatures (as low as 57°C). Heat exchangers also prevent corrosive geothermal fluids from damaging turbines, extending equipment lifespan by up to 30%. A 2022 report by the International Renewable Energy Agency (IRENA) found that optimized heat exchanger designs can reduce operational costs by 15-20%, making geothermal energy more competitive with fossil fuels. Additionally, modern plate-and-frame heat exchangers offer compact designs with 90% heat transfer efficiency, reducing plant footprint and installation costs. By maximizing energy extraction and minimizing waste, heat exchangers are indispensable for scalable, sustainable geothermal power generation.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Plate heat exchanger gaskets perform 5 key roles: ...

More

A gasket in heat exchanger seals surfaces, blocks ...

MoreAPI 662 defines standards for plate heat exchanger...

More

You can see clear differences between welded block...

More

Maximize energy efficiency and cut costs by select...

More

Commercial heat exchangers boost energy efficiency...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

John Smith

Mechanical EngineerThe heat exchanger performs exceptionally well in our geothermal power plant, with high efficiency and minimal maintenance required.

Emily Davis

Plant OperatorReliable and durable heat exchanger that has significantly improved our plant's thermal efficiency. Highly recommended for geothermal applications.

Robert Johnson

Energy ConsultantThis heat exchanger is a game-changer for geothermal power plants. Its robust design and excellent heat transfer capabilities make it a top choice.

Sarah Wilson

Project ManagerWe installed this heat exchanger in our geothermal facility, and it has exceeded our expectations in terms of performance and longevity.