5 key roles of plate heat exchanger gaskets.

Plate heat exchanger gaskets perform 5 key roles: ...

More

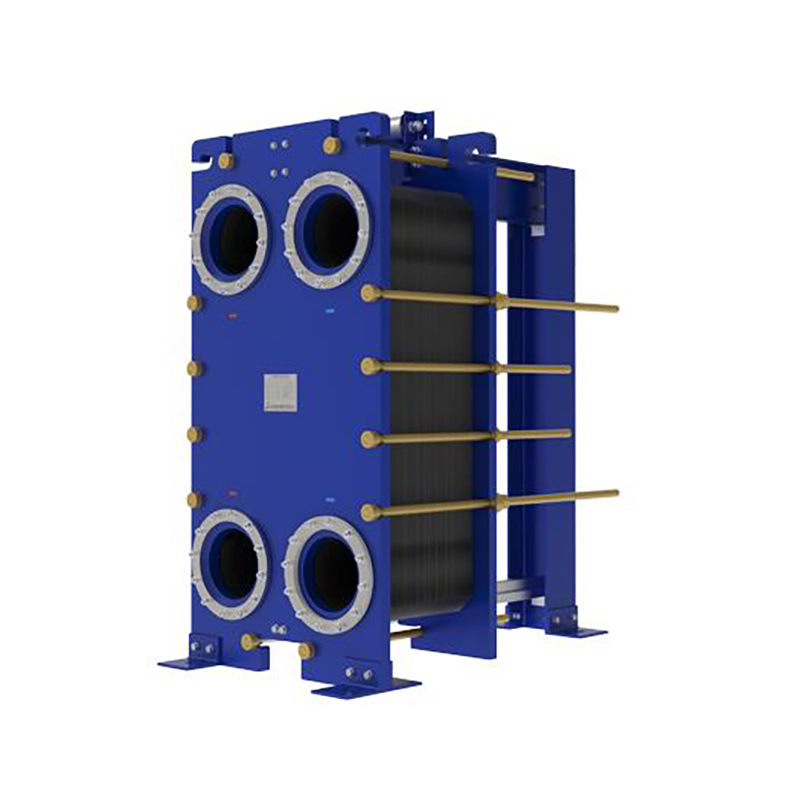

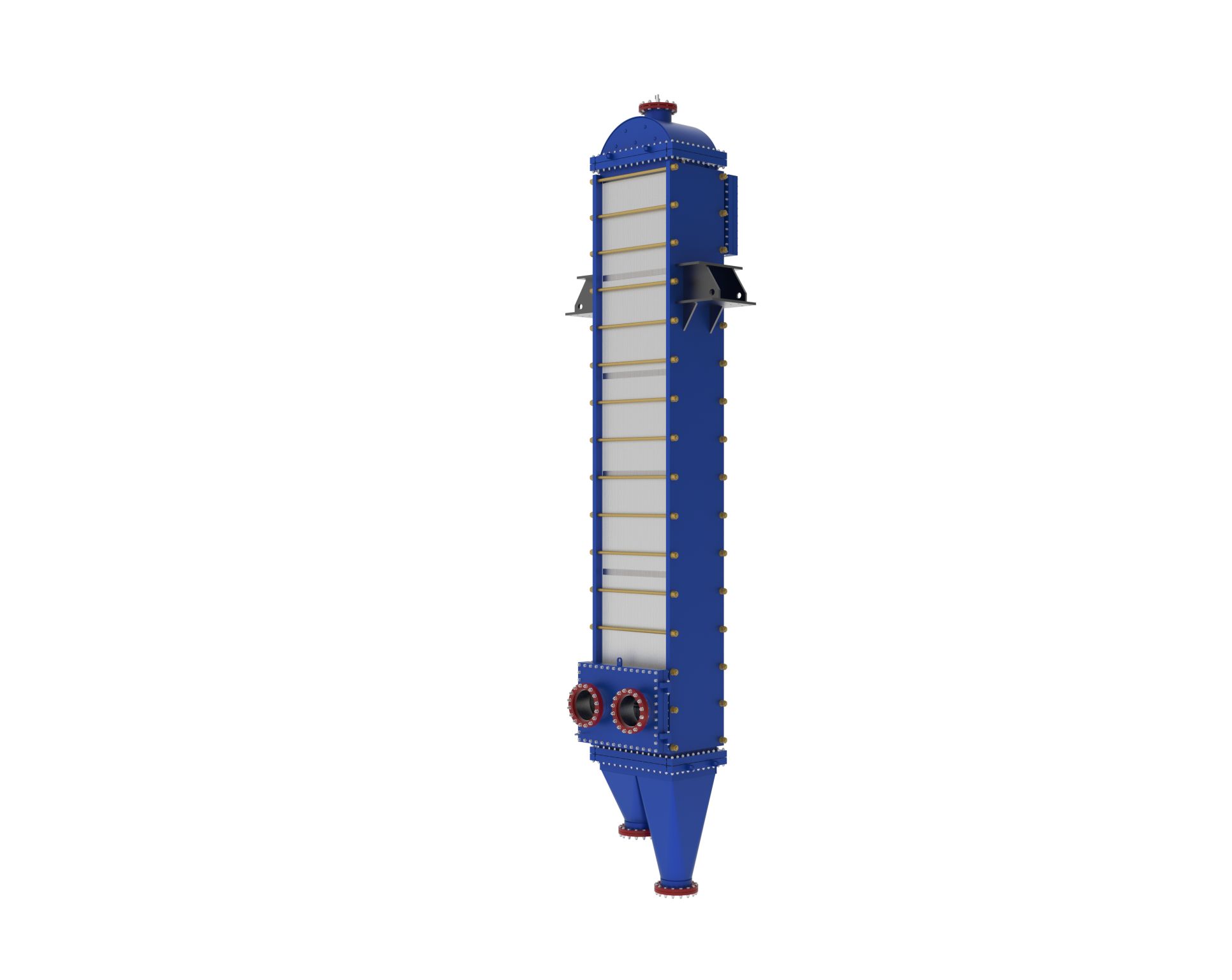

Heat exchangers are critical components in power plants, ensuring optimal thermal efficiency and reducing operational costs. They transfer heat between fluids without mixing them, enabling processes like steam generation, condensation, and waste heat recovery. In coal, gas, nuclear, and renewable energy plants, heat exchangers improve energy conversion rates, directly impacting fuel consumption and emissions. For example, studies show that advanced heat exchangers can boost power plant efficiency by up to 10%, saving millions annually in fuel costs.

Modern power plants rely on heat exchangers to meet stringent environmental regulations and enhance sustainability. By recovering waste heat, these systems reduce greenhouse gas emissions—up to 20% in combined-cycle gas plants. Leading manufacturers like Alfa Laval and Siemens report that high-performance plate-and-shell heat exchangers can withstand extreme temperatures (up to 1,000°C) and pressures, ensuring longevity in harsh conditions. Real-world data from the U.S. Energy Information Administration (EIA) highlights that power plants using optimized heat exchangers achieve 5-15% higher output with the same fuel input. Investing in cutting-edge heat exchange technology is no longer optional but a competitive necessity for power generation.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Plate heat exchanger gaskets perform 5 key roles: ...

More

A gasket in heat exchanger seals surfaces, blocks ...

MoreAPI 662 defines standards for plate heat exchanger...

More

You can see clear differences between welded block...

More

Maximize energy efficiency and cut costs by select...

More

Commercial heat exchangers boost energy efficiency...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

John Smith

Mechanical EngineerThe heat exchanger performed exceptionally well in our power plant, significantly improving efficiency and reducing downtime. Highly recommended!

Emily Davis

Plant OperatorReliable and durable heat exchanger that meets our power plant's demands. Installation was straightforward, and maintenance is minimal.

Michael Johnson

Maintenance SupervisorThis heat exchanger has been a game-changer for our facility. It handles high temperatures and pressures with ease, and the build quality is outstanding.

Sarah Wilson

Process EngineerGreat product for power plant applications. The heat transfer efficiency is impressive, and it integrates seamlessly with our existing systems.