5 key roles of plate heat exchanger gaskets.

Plate heat exchanger gaskets perform 5 key roles: ...

More

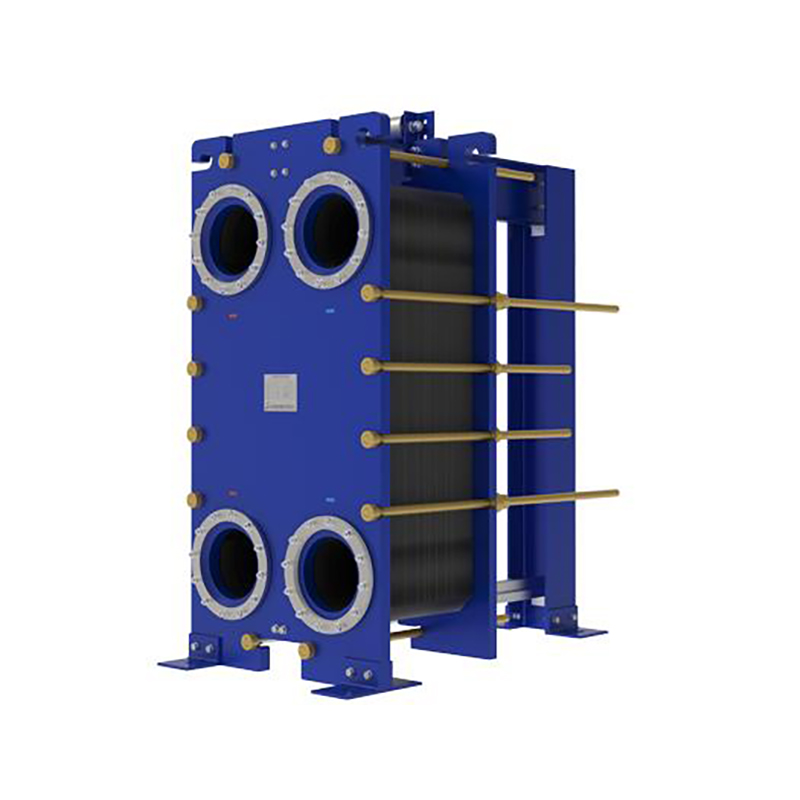

Heat exchangers are fundamental components in numerous industrial, commercial, and residential applications, designed to transfer heat between two or more fluids without mixing them. A common question from engineers, procurement managers, and facility operators is: "How many heat exchanger types are there?" The answer is not a single number, as classification is based on multiple factors. Primarily, they are categorized by their flow arrangement, construction method, and heat transfer mechanism. The four most prevalent and fundamental types, widely recognized across engineering handbooks and manufacturer catalogs, are Shell and Tube, Plate, Finned Tube (Air-Cooled), and Regenerative exchangers. However, expanding the classification to include variations based on design and application reveals a broader spectrum of 8 to 12 common types. These core four can be broken down further; for instance, plate exchangers include brazed plate, gasketed plate-and-frame, and welded plate variants. Other significant types include adiabatic wheel, plate fin, pillow plate, and spiral heat exchangers. Therefore, while the core types are few, the total number of distinct, commercially significant designs is approximately a dozen, each with numerous sub-variants tailored for specific pressures, temperatures, and media.

The selection of the correct type is critical for operational efficiency, cost-effectiveness, and system longevity. The shell and tube heat exchanger, one of the most versatile and common types, is extensively used in high-pressure applications like power generation (steam condensers) and oil refineries (crude oil cooling). According to market analyses, this segment held a significant share of the global market, valued at over USD 8 billion in 2022, underscoring its industrial dominance. Plate heat exchangers, renowned for their compact size and high efficiency in low to medium-pressure duties, dominate the HVAC, food and beverage, and pharmaceutical industries. Data from Grand View Research indicates the plate segment is experiencing rapid growth, driven by its superior thermal efficiency which can be up to 90% greater than shell and tube designs in certain applications, leading to substantial energy savings. For gas-to-gas heat transfer or situations where one fluid is air, finned tube or air-cooled heat exchangers are the default choice, prevalent in automotive radiators and air conditioning condensers. Spiral heat exchangers are the preferred solution for fluids containing solids or sludges, such as in wastewater treatment or pulp and paper production, as their single channel minimizes clogging. The decision-making process involves a detailed analysis of operating parameters: temperature ranges, pressure limits, the nature of the fluids (including fouling potential), space constraints, maintenance requirements, and capital vs. operational cost trade-offs. For example, a gasketed plate-and-frame exchanger offers easy maintenance and high efficiency but may not be suitable for high-temperature fluids that degrade gaskets, where a brazed or welded model would be chosen. Ultimately, partnering with an experienced manufacturer is essential to navigate these variables and specify the optimal heat exchanger type for a specific process, ensuring maximum performance and return on investment.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Plate heat exchanger gaskets perform 5 key roles: ...

More

A gasket in heat exchanger seals surfaces, blocks ...

More

API 662 defines standards for plate heat exchanger...

More

Plate heat exchangers are becoming more popular be...

More

Compare top frame plate heat exchanger models for ...

More

User reviews show the american standard heat excha...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

Michael Chen

Maintenance EngineerWe replaced our old shell and tube exchanger with this new unit. The performance jump is incredible. It handles our high-pressure steam condensate duties with ease and the maintenance access is a game-changer for our team. Highly recommended for heavy industrial applications.

Sarah Johnson

HVAC Project ManagerAs a project manager specializing in commercial HVAC, plate heat exchangers are our go-to for space and energy efficiency. This particular model's compact design and gasket material are top-notch, making installation in tight mechanical rooms a breeze. A reliable and efficient solution.

David Rodriguez

Plant OperatorThis air-cooled heat exchanger has been a workhorse on our gas compression platform. It's drastically reduced our water usage and treatment costs. It's robust and handles the elements well. Took one star off for the initial fan balancing required, but otherwise a solid piece of equipment.

Emily Watkins

Process EngineerThe implementation of this spiral heat exchanger solved a chronic fouling issue we had with a difficult slurry. The self-cleaning action is not just marketing talk; it has significantly reduced downtime for cleaning. A perfect fit for challenging duties in food processing.