Heater Exchanger The Secret to Lower Energy Bills

How a Heater Exchanger Cuts Energy Waste

A furnace's ability to lower energy bills hinges on two critical functions: maximizing heat capture and minimizing heat loss. The heat exchanger is engineered to excel at both. It works tirelessly behind the scenes to ensure the fuel your furnace burns is converted into comfort for your home, not wasted energy sent up a chimney.

Capturing and Transferring Heat

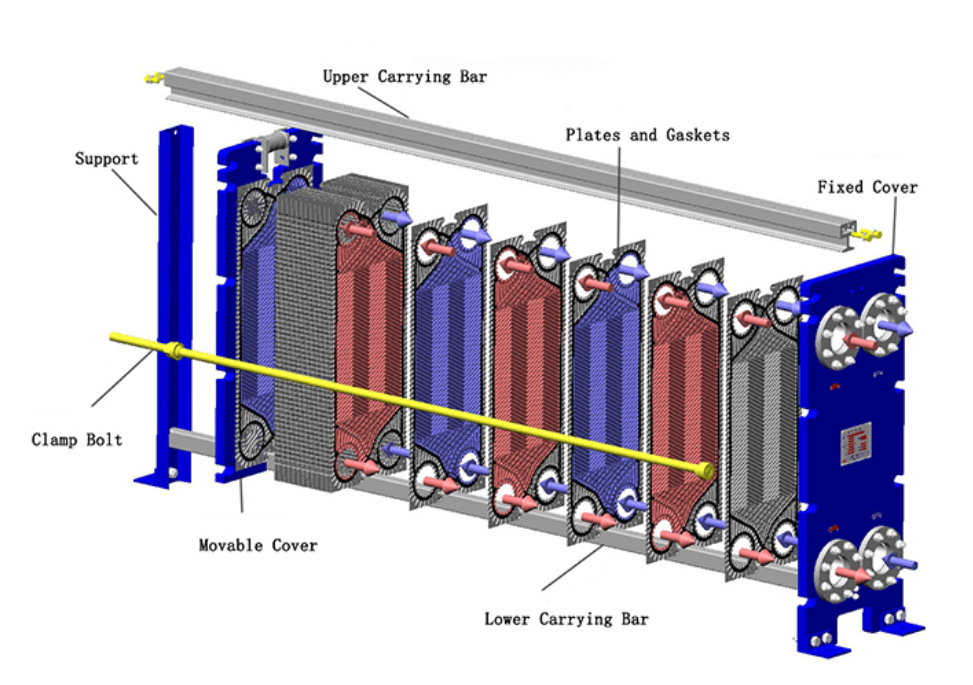

The primary job of a heat exchanger is to act as a bridge for thermal energy. It captures the intense heat generated during the furnace's combustion cycle and efficiently transfers it to the air circulating through your home. This process happens in a highly controlled sequence.

·Initial Heat Capture: Hot combustion gases from the furnace's burners flow through a series of metal tubes or chambers that make up the primary heat exchanger. The metal absorbs this thermal energy, becoming extremely hot.

·Air-to-Metal Transfer: A blower motor then pushes cool return air from your home across the hot exterior surfaces of these tubes. The air absorbs the heat from the metal, warming up significantly before it is distributed through your ductwork.

The genius of modern design lies in maximizing this transfer. Engineers increase the unit's effectiveness by expanding its surface area without making the furnace bigger. Finned tube fabrication, for instance, adds thin metal fins that extend outward from the main tubes. This design dramatically increases the area available for heat transfer. Key design elements that boost this efficiency include:

·Fin and Tube Design: The height, thickness, and spacing of fins are precisely calculated. Similarly, the diameter and arrangement of the tubes (e.g., staggered layouts) create turbulence in the airflow, forcing more air to make contact with the hot surfaces and absorb more heat.

·Compact Power: This focus on surface area density allows a modern heater exchanger to be incredibly effective in a small footprint, reducing the overall size of the furnace unit.

Preventing Heat Loss

A furnace's efficiency is ultimately defined by how much heat it keeps versus how much it loses. In older or less efficient furnaces, a significant amount of heat escapes with the exhaust gases through the flue vent. The Annual Fuel Utilization Efficiency (AFUE) rating measures this, telling you what percentage of fuel becomes usable heat.

| Furnace Type | AFUE Rating Range | Potential Heat Loss |

|---|---|---|

| Mid-efficiency | 80% to 83% | 17% to 20% |

| High-efficiency | 90% to 98.5% | 1.5% to 10% |

As the table shows, a mid-efficiency furnace can waste up to a fifth of its fuel. High-efficiency furnaces prevent this waste by using a secondary heat exchanger. This component gives the furnace a second chance to capture escaping heat.

It works by cooling the hot exhaust gases even further. This cooling process causes water vapor within the exhaust to condense into liquid. This phase change releases a powerful form of energy known as latent heat. The secondary heat exchanger captures this latent heat and uses it to help warm the air, boosting the furnace's AFUE rating to 90% and above. This recovered energy is pure savings, as it would otherwise have been lost completely.

A Note on Efficiency LossThe energy-saving performance of a heat exchanger can be compromised by poor maintenance. Problems like fouling (buildup of soot or scale), corrosion, and leaks reduce the unit's ability to transfer heat effectively. These issues not only waste energy but can also lead to costly equipment failures.

Understanding Your Furnace's Efficiency Rating (AFUE)

When shopping for a new furnace, you will encounter a critical yellow sticker displaying its Annual Fuel Utilization Efficiency (AFUE) rating. This number is the single most important indicator of a furnace's energy-saving potential.

What is AFUE?

AFUE is a standardized metric that measures how efficiently a furnace converts fuel into usable heat over a year. The U.S. Department of Energy requires this rating on all new furnaces. A higher AFUE percentage signifies greater efficiency. For instance, a furnace with a 90% AFUE rating converts 90 cents of every fuel dollar into warmth for your home. The remaining 10 cents are lost as exhaust through the chimney.

Federal standards set minimum efficiency levels, which vary by region:

·Northern States: New furnaces must have a minimum AFUE of 95%.

·Southern States: The minimum AFUE rating is 90%.

This difference in wasted energy becomes significant over the life of the furnace.

| AFUE Rating | Fuel Used for Heat | Fuel Wasted as Exhaust |

|---|---|---|

| 80% | 80% | 20% |

| 95% | 95% | 5% |

Choosing a higher AFUE model directly translates to lower monthly energy bills.

The Heat Exchanger's Role in a High AFUE

The heat exchanger is the engine that drives a furnace's AFUE rating. A standard furnace uses a primary heat exchanger to transfer heat. However, high-efficiency models with AFUE ratings of 90% or more achieve this performance by adding a secondary heat exchanger.

This second component is the key to minimizing waste. It captures additional heat from the exhaust gases before they exit your home.

This process is so effective that it cools the gases enough to cause water vapor to condense, releasing even more latent heat. This recovered energy is then used to warm your home. A modern heater exchanger system with this condensing technology ensures that almost no energy is wasted, pushing efficiency to 98% in top-tier models and maximizing your savings.

Types of Heat Exchangers and Their Impact on Savings

The design and materials of a furnace's heat exchanger system directly determine its efficiency and your potential savings. Furnaces are built with either a single primary heat exchanger or a dual system that adds a secondary unit for maximum energy recovery.

Primary vs. Secondary Heat Exchangers

Every furnace contains a primary heat exchanger. Its job is to transfer heat directly from the burning fuel to the air circulating through your home. Standard-efficiency furnaces, which deliver around 80% AFUE, rely solely on this component. These models are still manufactured and sold today, particularly in regions with milder climates.

High-efficiency furnaces achieve 90% AFUE ratings or higher by adding a secondary heat exchanger. This component is the key to unlocking significant energy savings.

·It captures additional heat from the hot exhaust gases that would otherwise escape.

·This process cools the gases enough to cause condensation, which releases powerful latent heat.

·The system captures this latent heat and uses it to further warm your home’s air, maximizing fuel efficiency.

How Construction Materials Affect Savings

The material used to build a heater exchanger affects its durability and long-term performance. The two most common materials are aluminized steel and stainless steel. Each has distinct properties that influence efficiency and lifespan.

Material Choice Matters: Selecting the right material is critical. A poor choice can lead to premature corrosion, reduced efficiency, and expensive repairs.

Engineers choose materials based on their role. Aluminized steel is often used for primary heat exchangers due to its excellent heat conduction. However, stainless steel is superior for secondary heat exchangers because it better resists the corrosive moisture created during the condensation process.

| Feature | Aluminized Steel | Stainless Steel |

|---|---|---|

| Heat Transfer | Better heat conduction | Good heat conduction |

| Corrosion Resistance | Less corrosion resistant | Better corrosion resistance |

| Cost | Less expensive | More expensive |

A durable, corrosion-resistant material ensures the system maintains peak efficiency, preventing energy waste and saving you money over the furnace's lifetime.

Maintenance for Peak Efficiency and Savings

A high-efficiency heat exchanger saves money only when it operates correctly. Simple maintenance routines are essential for preserving its performance and preventing costly breakdowns. These tasks protect your investment and ensure your furnace runs safely and efficiently.

The Importance of Clean Air Filters

A furnace's air filter is its first line of defense. A clogged filter restricts airflow, forcing the furnace's blower motor to work harder and run longer. This extra effort wastes energy. The U.S. Department of Energy states that replacing a dirty filter can lower a furnace's energy consumption by 5% to 15%.

Choosing the right filter also matters. Filters use a Minimum Efficiency Reporting Value (MERV) to rate their effectiveness. A higher MERV rating captures smaller particles but can also reduce airflow if it is too high for the system. For most homes, a MERV rating between 8 and 13 offers a good balance.

·MERV 8: Good for homes with no pets or allergies.

·MERV 11: Recommended for homeowners with pets or mild allergies.

·MERV 13: Best for households with severe allergies or respiratory issues.

Why Annual Inspections Save You Money

While homeowners can change filters, an annual professional inspection is crucial for long-term savings and safety. A technician performs checks that homeowners cannot. These inspections identify issues before they become expensive failures. A heat exchanger replacement can cost over $1,500, while an annual maintenance plan typically costs between $150 and $500.

A cracked heat exchanger is a serious safety hazard. It can allow colorless, odorless carbon monoxide (CO) gas to leak into a home, causing symptoms like headaches, dizziness, and even death.

During an inspection, a technician specifically examines the heat exchanger for:

·Cracks or corrosion that reduce efficiency and pose safety risks.

·Flue blockages that prevent proper venting.

·Carbon monoxide leaks using specialized detectors.

This preventative care ensures the system operates at peak efficiency, keeps energy bills low, and protects your family.

The heater exchanger is the central component responsible for turning fuel into heat efficiently. A well-maintained, high-quality unit is a direct path to significant, long-term reductions in energy bills, often lasting 15 to 20 years. Homeowners should check air filters monthly and schedule annual HVAC inspections to ensure their system continues saving them money.

FAQ

What are signs of a failing heat exchanger?

Look for rattling noises, a flickering yellow burner flame, or strong odors. These signs require an immediate professional inspection to ensure safety and prevent further damage.

How long does a heat exchanger last?

A well-maintained heat exchanger typically lasts 15 to 20 years. Regular annual inspections are key to reaching this lifespan and ensuring the unit's continued efficiency and savings.

Can I clean my own heat exchanger?

No. Cleaning this component is a job for a professional. A qualified HVAC technician must perform this task for several important reasons:

·It requires specialized tools and training.

·Improper service can cause damage.

·It ensures safe system operation.