How 3D Printing is Revolutionizing Heat Exchanger Manufacturing

Core Innovations: How 3D Printing Shatters Traditional Limits

Additive manufacturing fundamentally alters the approach to creating thermal management solutions. It removes long-standing constraints, allowing engineers to prioritize efficiency and reliability over outdated production methods. This shift introduces two transformative innovations.

Designing for Performance, Not Manufacturability

Traditional manufacturing methods like brazing, welding, and casting impose strict geometric limitations. Designers historically created heat exchangers based on what machines could produce, not what was thermally optimal. 3D printing liberates engineers from these constraints. They can now design directly for performance.

This freedom allows for the creation of incredibly complex internal geometries. Engineers utilize advanced shapes like Triply Periodic Minimal Surface (TPMS) structures. The gyroid is a prime example of a TPMS. These structures offer several key advantages:

·They split a volume into two separate, continuous domains, perfect for managing different fluid flows.

·They possess a very high surface-area-to-volume ratio, which maximizes convective heat transfer.

·They are self-supporting during the printing process, removing the need for internal supports that can obstruct flow.

·They exhibit quasi-isotropic structural properties, making them incredibly strong and resistant to high pressure from any direction.

The results are dramatic. Studies show gyroid structures achieve a 112% higher Nusselt number (a measure of heat transfer) compared to simple tube models. In experiments, they demonstrate a 55% increase in heat transfer performance over conventional designs while being just a fraction of the size.

Specialized software makes these complex designs possible. Engineering platforms like nTop give designers the tools to build and control these intricate geometries.

Creating Monolithic, Leak-Proof Units

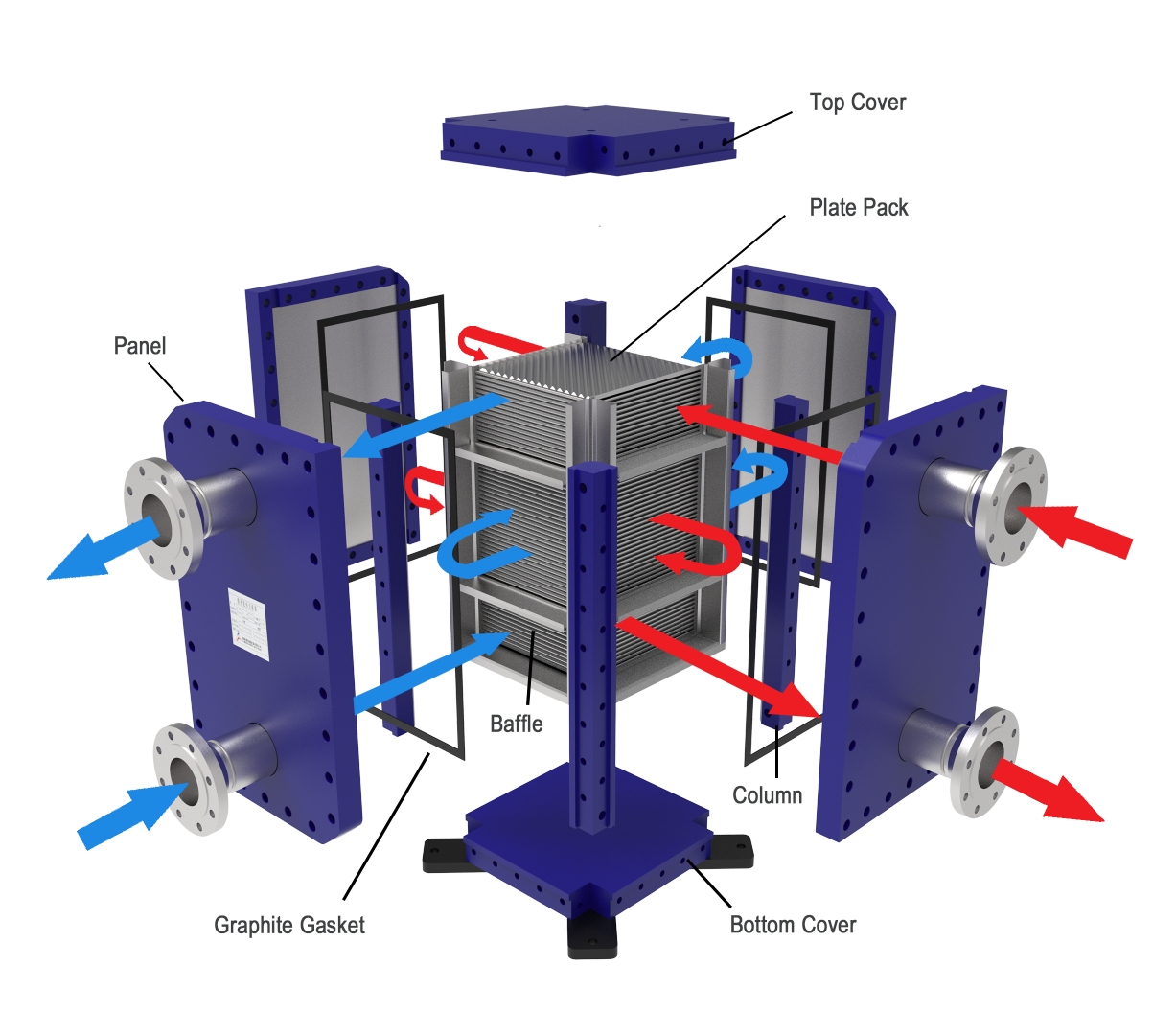

A conventional heat exchanger is an assembly of many individual parts. Tubes, fins, headers, and shells are all joined together by welding, brazing, or bolting. Each joint, seam, and gasket is a potential point of failure. The traditional manufacturing of heat exchangers introduces inherent risks.

Common causes of leaks in these assemblies include:

·Gasket Failure: Incorrect material choice leads to corrosion or degradation.

·Thermal Stress: Different metal parts expand and contract at different rates, causing flanges to warp and joints to crack.

·Hardware Issues: Bolts can loosen over time due to vibration and pressure, reducing gasket compression.

·Manufacturing Defects: Residual stresses from processes like tube bending can lead to stress corrosion cracking over time.

3D printing solves this problem by producing the entire heat exchanger as a single, continuous piece. This monolithic construction eliminates the primary sources of failure.

There are no seams to crack under thermal stress. There are no joints to corrode or fail. The entire component is a single, continuous piece of high-grade metal, making it inherently more robust.

This part consolidation drastically improves reliability and simplifies the entire system. The improved durability of a single-piece unit compared to a multi-part assembly is a core benefit of the additive manufacturing of heat exchangers.

| Feature | Traditional Manufacturing | 3D Printing (Additive) |

|---|---|---|

| Construction | Multi-part (bent, welded, brazed) | Monolithic (single-piece) |

| Primary Failure Points | Welds, seams, gaskets, brazed joints | Eliminated |

| Durability | Lower due to multiple stress points | Higher due to continuous structure |

By removing leak-prone joints, a 3D-printed heat exchanger reduces maintenance needs, minimizes downtime, and extends the operational life of the component.

Tangible Performance Gains from Additive Manufacturing of Heat Exchangers

The shift to additive manufacturing delivers concrete, measurable improvements in heat exchanger performance. By moving beyond the limits of traditional fabrication, engineers unlock new levels of efficiency, compactness, and hydraulic performance. These gains are not just theoretical; they are proven through rigorous testing and real-world application.

Boosting Thermal Efficiency

The primary goal of a heat exchanger is to transfer thermal energy effectively. 3D printing directly enhances this core function. The technology enables the creation of intricate internal structures, like Triply Periodic Minimal Surfaces (TPMS), that dramatically increase the surface-area-to-volume ratio. This increased area provides more opportunity for heat to move from one fluid to another.

A micro-architected gyroid lattice heat exchanger, for example, can feature a surface-to-volume ratio of 670 m²/m³. This dense internal structure led to a 55% increase in exchanger effectiveness compared to a highly efficient conventional design.

This boost in performance is consistent across different studies.

·TPMS-based structures have shown a 63% improvement in the overall heat transfer coefficient compared to traditional designs.

·At the same pumping power, a gyroid TPMS design improved the Nusselt number (a direct measure of convective heat transfer) by 13% over a standard straight tube.

Even small details in the printing process can be fine-tuned to maximize heat transfer. Post-processing techniques, like sanding the printed part, can further improve performance by creating a smoother surface for fluid flow.

| Sample Description | Heat Transfer Coefficient (W/m²K) |

|---|---|

| 0.1 mm layer height | 72 |

| 0.3 mm layer height | 85 |

| Sanded 0.3 mm layer height | 101 |

Reducing Size and Weight

A direct result of higher thermal efficiency is the ability to drastically reduce the size and weight of the component. Since a 3D-printed heat exchanger can transfer more heat within a smaller volume, it can achieve the same performance as a much larger, heavier conventional unit. This benefit, often referred to as improving SWaP (Size, Weight, and Power), is critical in industries like aerospace and high-performance automotive.

This reduction is possible because designers are no longer limited by the constraints of traditional assembly. They can use every cubic millimeter of space to its full potential. The result is a component that is not only smaller but also more efficient and cost-effective due to reduced material usage.

| Feature | Conventional Manufacturing (CM) | Additive Manufacturing (AM) |

|---|---|---|

| Design Capabilities | Limited to simple geometries; requires assembly of multiple parts. | High design freedom; produces complex, integrated, and customized shapes. |

| Performance | Design flexibility is limited, restricting optimization potential. | Customized designs increase surface area and optimize flow for maximum performance. |

Minimizing Pressure Drop

An effective heat exchanger must not only transfer heat well but also allow fluid to pass through it with minimal resistance. This resistance, known as pressure drop, requires energy to overcome, usually in the form of pumping power. High pressure drop can negate the benefits of good thermal performance by reducing the overall system's efficiency.

3D printing gives engineers powerful tools to design for smooth, efficient fluid flow.

Computational Fluid Dynamics (CFD): Engineers use CFD simulations to digitally test and refine designs. They can model how fluid moves through complex channels, allowing them to select geometries that maximize heat transfer while keeping pressure drop low.

Topology Optimization: This advanced software uses algorithms to generate the most efficient structure possible based on a set of performance goals. It creates organic, streamlined flow paths that a human designer might never conceive, guiding fluid smoothly through the exchanger.

AI-Driven Optimization: Modern approaches like Multi-objective Bayesian optimization (MOBO) use artificial intelligence to balance competing goals. An AI can optimize dozens of geometric parameters at once to find a design that delivers the best possible combination of high thermal efficiency and low pressure drop.

Success Story: An AI-optimized heat exchanger achieved approximately 35% higher heat transfer per unit volume while maintaining a lower pressure drop than its conventional counterparts. This demonstrates how the advanced design freedom in the manufacturing of heat exchangers leads to superior, holistic performance.

Key 3D Printing Technologies and Materials

Choosing the right technology and material is crucial for creating high-performance heat exchangers. Specific printing processes enable the use of advanced metals, each offering unique benefits for different thermal management challenges.

Dominant Processes: Selective Laser Melting (SLM) and Direct Energy Deposition (DED)

Selective Laser Melting (SLM) is the most common additive method for producing complex metallic parts. The process uses a high-powered laser to melt and fuse layers of fine metal powder, building a solid component from a 3D model. SLM is preferred for intricate heat exchanger geometries for several reasons:

·It produces complex, net-shape parts in a single step.

·It reduces production time by eliminating multi-step assembly.

·It lowers costs by minimizing material waste.

·It fabricates customized freeform shapes with high precision.

Direct Energy Deposition (DED) is another key process, often used for repairing parts or adding material to existing components. However, SLM's ability to create fine, detailed internal structures makes it the dominant choice for novel heat exchanger designs.

Advanced Materials: From Aluminum to Superalloys

The material selection directly impacts a heat exchanger's performance, weight, and durability. Additive manufacturing supports a wide range of metals, from lightweight alloys to robust superalloys. This flexibility is critical in the modern manufacturing of heat exchangers.

Aluminum alloys are a popular choice due to their excellent balance of weight, thermal conductivity, and corrosion resistance.

| Category | Aluminum Alloys |

|---|---|

| Advantages | Lightweight, good thermal properties, high design freedom, and lower cost than titanium. |

| Disadvantages | Lower strength-to-weight ratio than titanium; not as strong as steel or nickel alloys. |

For extreme environments, engineers turn to nickel-based superalloys like Inconel 718 and 625. These materials offer:

·Exceptional strength at high temperatures.

·Excellent resistance to corrosion and pressure.

·High structural stability for demanding applications.

Research continues to push boundaries with materials like copper, whose high thermal conductivity is now accessible through new blue-light laser systems. Ceramic matrix composites are also being explored for their enhanced thermal stability.

Real-World Impact: Where 3D Printing Excels

Additive manufacturing is already delivering transformative results across several high-stakes industries. Engineers in these fields leverage 3D printing to solve critical thermal management challenges, creating components that were previously impossible to build.

Aerospace and Defense

The aerospace and defense sectors demand lightweight, reliable, and high-performance components. 3D printing meets these needs by producing compact heat exchangers with superior thermal efficiency. This technology is vital for next-generation aircraft and spacecraft.

·Airbus ZEROe Program: Conflux Technology created a 3D-printed heat exchanger for Airbus's hydrogen-electric propulsion system. The component manages heat from megawatt-class fuel cells, enabling progress toward zero-emission flight.

·NASA's MOXIE Instrument: A nickel-alloy heat exchanger was printed as a single piece for the Perseverance Mars rover. This monolithic design eliminated the need for welding, improving reliability for the mission-critical instrument.

High-Performance Automotive

Motorsports, including Formula 1, rely on 3D printing to gain a competitive edge. Teams use additive manufacturing to create highly optimized cooling systems that improve vehicle performance and packaging. PWR Advanced Cooling Technology produces heat exchangers for F1 cars using a specialized aluminum alloy approved by the FIA. The Formula Student Racing Team E-Stall also uses 3D-printed aluminum coolers to enhance their electric racecar's performance. These designs offer significant advantages:

·Faster Engine Cooling: Walls as thin as 200 microns create a massive internal surface area, improving heat removal.

·Reduced Weight: Complex, integrated designs achieve better performance in a smaller, lighter package.

Advanced Electronics and Data Centers

Modern electronics and data centers generate immense heat, requiring advanced cooling solutions. 3D printing enables a shift from bulky air cooling to compact, efficient liquid cooling.

Metal 3D printing enables unprecedented improvements in fluid dynamic applications for power electronic systems. It helps to improve system efficiency, optimize space utilization and reduce part weight.

EOS and CoolestDC collaborated to create leak-free, unibody cold plates for sustainable data centers, reducing manufacturing costs by over 50%. Similarly, a generatively designed copper CPU cooler achieved a 55% lower thermal resistance, showcasing the technology's power to cool high-performance components.

3D printing shifts design from manufacturing limits to performance goals. It unlocks new levels of efficiency and reliability. This technology enables compact, consolidated components. However, challenges remain before wider adoption.

·Engineers can be conservative about new methods.

·Removing internal powder is difficult and time-consuming.

·Traditional methods are often cheaper and easier to scale.

As the technology matures, 3D printing will become a standard for high-performance thermal management.

FAQ

What are the main benefits of 3D printing heat exchangers?

Additive manufacturing delivers several key advantages.

·It boosts thermal efficiency with complex internal geometries.

·It reduces component size and weight significantly.

·It creates monolithic units, eliminating leak points.

What materials are best for 3D-printed heat exchangers?

Engineers select materials based on application needs. Aluminum alloys offer good performance and low weight. Nickel superalloys like Inconel excel in extreme heat and pressure environments.

Is 3D printing more expensive than traditional methods?

Initial costs can be higher. However, the process saves on material waste and assembly labor. It provides significant long-term value through superior performance and reliability.