How Plate Air Preheaters Enhance Energy Savings in Industry

Many industries lose large amounts of energy as heat during production.

Over 60% of industrial energy escapes as heat, leading to billions in lost revenue each year.

The steel industry alone loses almost half of its energy input as heat, while glass and cement manufacturing see up to 40% of energy lost this way.

Sectors like chemicals and petrochemicals could improve efficiency by 20% through better heat recovery.

Regenerative solutions, such as the Plate Air Preheater, help capture this wasted heat. These systems lower operational costs, reduce fuel use, and support sustainability by minimizing emissions.

Plate Air Preheater Design

Structure and Materials

Shanghai Heat Transfer’s Plate Air Preheater features a compact and robust structure. The main body uses corrugated metal plates that create a large surface area for heat exchange. These plates form alternating channels for hot and cold air, which increases the contact between the two streams. Stainless steel construction ensures durability and resistance to corrosion, even in harsh industrial environments. This material choice also helps extend the lifespan of the equipment. The lightweight design allows for easier handling and installation in various settings.

Heat Exchange Principles

The Plate Air Preheater operates on advanced heat transfer principles. Hot exhaust gases flow on one side of the corrugated plates, while incoming air or process gas moves on the opposite side. The device uses either counterflow or crossflow configurations. In counterflow, the two streams move in opposite directions, which maximizes heat recovery. In crossflow, the streams move perpendicular to each other, which offers flexibility for different system layouts. As heat passes through the plate walls, it transfers from the exhaust gas to the incoming air. This process increases the temperature of the air before it enters boilers or furnaces, improving overall energy efficiency and reducing fuel use.

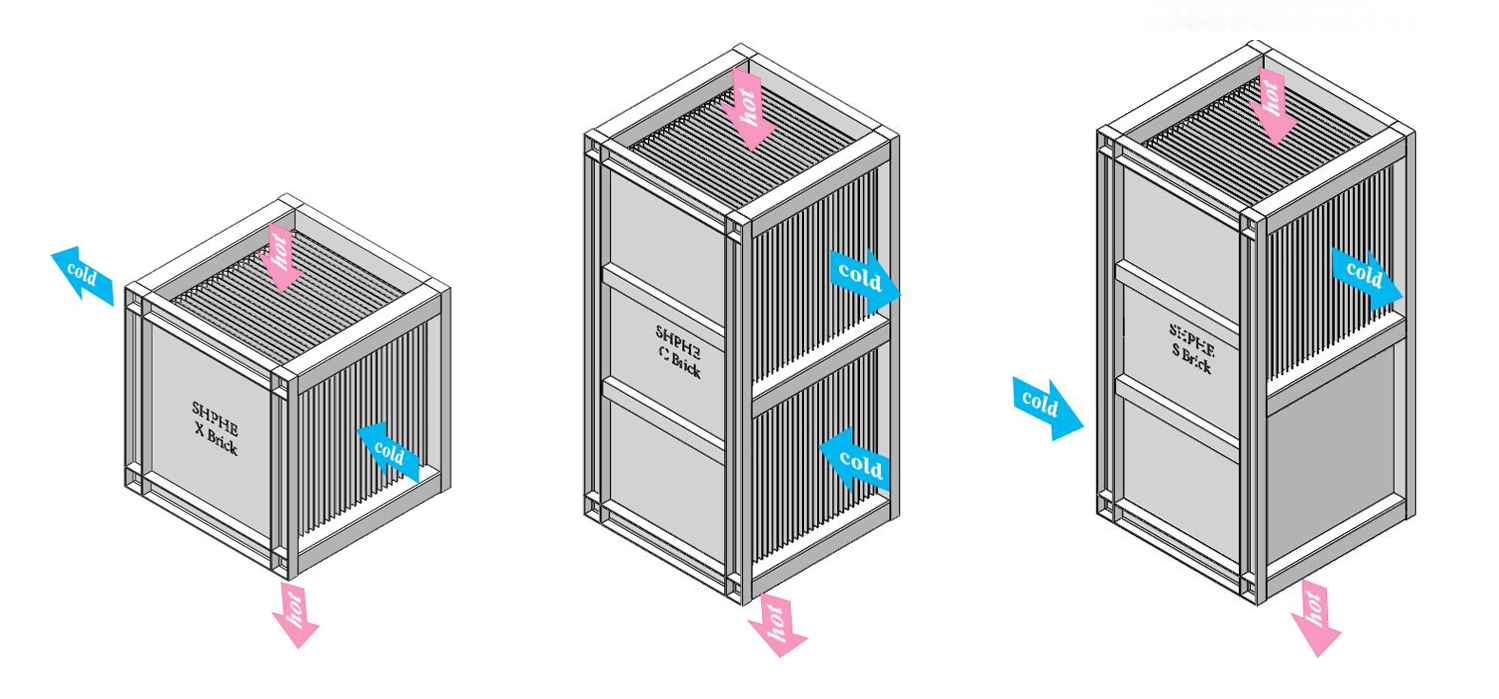

Modular Features

The modular design of the Plate Air Preheater brings several advantages to industrial operations:

Shipping becomes easier because modules can be transported separately.

Installation is simpler, as workers can assemble the system on-site.

Maintenance tasks are more straightforward, since individual modules can be accessed or replaced without disturbing the whole unit.

Retrofitting existing systems is less complex, allowing upgrades without major changes.

This modular approach also supports customization. Companies can adjust the number and size of modules to fit their specific heat recovery needs. The flexibility of the design makes the Plate Air Preheater suitable for a wide range of industrial applications.

Energy Efficiency Mechanisms

Waste Heat Recovery

Industrial processes generate large amounts of heat that often escape through exhaust streams. The plate air preheater captures this waste heat and puts it to work. It uses a system of corrugated metal plates to transfer heat from hot exhaust gases to incoming air. This process increases the temperature of the air before it enters the heating system. The result is a significant boost in energy recovery and overall efficiency.

Heat recovery systems capture waste heat for reuse, improving energy efficiency in industrial processes.

These systems convert waste heat into preheated air, hot water, or steam, which is essential for plate air preheater operation.

By utilizing recovered heat, these systems help reduce fuel consumption and greenhouse gas emissions.

Economizers, a type of industrial heat exchanger, recover waste heat from exhaust gases and preheat incoming fluids such as combustion air.

This process enhances the thermal efficiency of combustion systems, leading to significant fuel savings.

ShangHaiHeattransfer’s plate air preheater stands out due to its high heat transfer coefficient. The advanced plate heat exchanger design maximizes the contact area between hot and cold streams. This feature allows for rapid and efficient heat exchange, making it ideal for demanding industrial heat exchanger applications.

Fuel Savings

When the plate air preheater raises the temperature of incoming air, the heating system needs less fuel to reach the desired temperature. This improvement in efficiency leads to direct fuel savings. For every 50°C increase in air temperature, fuel consumption drops by 1.5–2.0%. In large-scale operations, this reduction can translate into substantial cost savings over time.

Plate air preheaters recover waste heat from flue gases to preheat combustion air.

This process enhances combustion efficiency, leading to a reduction in fuel consumption.

Advanced preheater technology can save 3–3.5 kg oil equivalent per ton of clinker in cement production.

Experimental results have shown up to a 35% reduction in energy consumption with advanced heat exchanger designs.

The performance of ShangHaiHeattransfer’s plate air preheater ensures that industries can achieve these savings consistently. The modular design and high heat transfer efficiency make it a reliable solution for continuous industrial use.

Emissions Reduction

Lower fuel consumption means fewer emissions. By recovering heat that would otherwise be lost, the plate air preheater helps reduce the amount of fuel burned in industrial processes. This reduction leads to lower greenhouse gas emissions and supports compliance with environmental regulations.

Note: Many industries face strict limits on emissions. Using a plate air preheater not only improves efficiency but also helps companies meet these requirements.

The use of stainless steel and a compact design further minimizes particulate release and thermal pollution. As a result, the plate air preheater supports sustainable practices and helps protect the environment. Its role in energy recovery and emissions reduction makes it a key component in modern industrial systems.

Industrial Applications

Key Industries

Many industries rely on the plate air preheater to improve energy efficiency and reduce costs. Power and utility companies use this technology to recover heat from exhaust gases. Oil and gas facilities install these devices to meet strict energy regulations and lower fuel expenses. Chemical plants benefit from better heat management and safer operations. Metal and steel manufacturers use plate air preheaters to handle high-temperature processes and boost performance. The food and beverage sector also adopts this industrial heat exchanger to maintain product quality while saving energy. These industries choose plate air preheaters because of growing industrialization, urbanization, and advances in heat transfer technology.

Typical Uses

Industrial facilities use plate air preheaters in several ways. They often recover heat from flue gases and transfer it to incoming air or process gas. This process preheats the air before it enters boilers, furnaces, or reactors. The result is higher efficiency and lower fuel use. Many companies use plate air preheaters to support heat exchanger applications that demand reliable and consistent performance. These devices help reduce energy waste, cut emissions, and improve overall system efficiency. Operators value the ability to maintain stable temperatures and protect equipment from thermal stress.

Note: Plate air preheaters play a key role in meeting environmental standards and supporting sustainable industrial growth.

Installation Flexibility

The modular design of the plate air preheater allows for easy adaptation in different industrial settings. Workers can transport and assemble modules on-site, which saves time and reduces installation costs. Maintenance teams can access or replace individual modules without shutting down the entire system. This flexibility supports upgrades and retrofits in existing plants. Companies can customize the number and size of modules to match their specific heat recovery needs. The compact structure fits into tight spaces, making it suitable for both new and older facilities.

Industrial Heat Exchanger Comparison

Plate vs. Rotary

Rotary heat exchangers use a rotating wheel to transfer heat between air streams. Plate air preheaters use fixed plates with alternating channels. Rotary units often require more space and moving parts. Plate designs have a compact structure and fewer mechanical components. Maintenance for rotary exchangers can be complex because of the moving wheel. Plate air preheaters allow for easier cleaning and part replacement. The plate heat exchanger design also reduces the risk of air leakage between streams. In many industrial settings, plate air preheaters provide higher efficiency and more reliable performance.

Plate vs. Tubular

Tubular heat exchangers use bundles of tubes to move heat from one fluid to another. Plate air preheaters use flat, corrugated plates to create large surface areas for heat transfer. Tubular designs can be bulky and heavy. Plate models offer a lightweight and compact alternative. Cleaning tubular exchangers often requires full disassembly. Plate air preheaters allow for quick access to individual modules. This feature saves time and reduces downtime in industrial operations. The plate heat exchanger also handles heat transfer with less fouling, which means less buildup and better long-term performance.

Unique Advantages

Plate air preheaters stand out in industrial heat exchanger applications for several reasons:

High heat transfer coefficient: The corrugated plate design increases turbulence, which boosts heat exchange.

Low fouling resistance: Smooth surfaces and easy access help prevent buildup.

Modular structure: Users can add or remove modules to match energy needs.

Compact size: The design fits into tight spaces and reduces installation costs.

Tip: Choosing a plate air preheater can improve efficiency, lower maintenance, and support sustainable energy use in industrial plants.

Feature | Plate Air Preheater | Rotary Exchanger | Tubular Exchanger |

|---|---|---|---|

Heat Transfer Surface | Corrugated Plates | Rotating Wheel | Tube Bundles |

Efficiency | High | Moderate | Moderate |

Maintenance | Easy | Complex | Moderate |

Size | Compact | Large | Bulky |

Fouling Resistance | Low | Moderate | High |

Plate air preheaters deliver strong performance and energy savings. Their advanced design makes them a top choice for modern industrial systems.

Maintenance and Optimization

Routine Care

Routine maintenance keeps the plate air preheater working at peak performance. Operators should follow these best practices:

Clean the heat exchanger regularly to prevent fouling and buildup.

Apply corrosion protection to all exposed surfaces.

Optimize air flow through the heat exchanger to maximize heat transfer.

Monitor the air preheater's performance to spot areas for improvement.

These steps help maintain high thermal efficiency and support reliable energy recovery in industrial heating and cooling systems.

Performance Tips

Operators can use several strategies to boost efficiency and extend the lifespan of the plate air preheater. The table below highlights practical tips for continuous-use industries:

Tip | Description |

|---|---|

Use acoustic or electromagnetic methods to remove deposits without shutting down the system. | |

Corrosion Mitigation | Install sacrificial anodes or use cathodic protection to increase durability and efficiency. |

Optimizing Heat Recovery | Add economizers and regenerative air preheaters to capture more heat and reduce fuel use. |

These methods improve energy transfer and help maintain stable performance. Operators who use these tips see better results in both heating and cooling systems.

Support Services

Shanghai Heat Transfer offers strong engineering support for plate air preheater users. The company provides a global service network that operates 24/7 for technical consultation and after-sales support. Maintenance strategies rely on teamwork among production, technical, and service teams to ensure rapid response and minimal downtime. The table below shows how support services impact long-term reliability:

Aspect | Details |

|---|---|

Excellent support enhances reliability | |

Compliance | Adherence to ISO standards ensures quality |

Process Efficiency | Minimal downtime contributes to reliability |

Strong support helps maintain high performance and energy efficiency. Reliable service ensures that industrial facilities can depend on their plate air preheater for consistent energy recovery and optimal thermal efficiency.

Plate air preheaters deliver strong benefits for industrial energy savings. Many facilities use air-to-air heat recovery units to capture waste heat from manufacturing. Recycled heated air supports other assembly areas, which leads to lower energy use. This method prevents heated air from being lost outside. Companies see improved energy efficiency and reduced costs. These solutions also help industries reach sustainability goals.

FAQ

What is a plate air preheater?

A plate air preheater is a heat exchanger that transfers heat from exhaust gases to incoming air. This process increases the temperature of the air before it enters industrial equipment. Many industries use this device to improve energy efficiency and reduce fuel costs.

Where can plate air preheaters be used?

Plate air preheaters have many applications. They work in power plants, chemical factories, oil refineries, and food processing plants. These devices support applications that require heat recovery, emissions reduction, and improved system performance.

How do plate air preheaters improve energy savings?

Plate air preheaters recover waste heat from exhaust gases. They use corrugated plates to transfer heat to incoming air. This process reduces the need for extra fuel. Many applications benefit from lower energy use and reduced emissions.

What makes plate air preheaters suitable for different applications?

The modular design allows easy customization. Operators can add or remove modules to fit specific applications. This flexibility supports a wide range of industrial applications, including retrofits and new installations.

Are plate air preheaters easy to maintain?

Yes. The modular structure allows workers to access and clean individual modules. This feature reduces downtime. Many applications benefit from simple maintenance routines and reliable performance.