How Plate Air Preheaters Improve Industrial Efficiency

Plate air preheaters transform industrial processes by recovering waste heat, directly boosting energy efficiency. SHPHE stands out in the field of heat recovery equipment, offering advanced air preheaters known for durability and performance. Facilities using air preheaters can see around 3% fuel savings, which highlights the importance of selecting the right equipment for each application.

Plate Air Preheater Working Principle

Heat Exchange Process

Plate air preheaters operate by transferring heat from high-temperature flue gas to combustion air. This process increases the temperature of the incoming air, resulting in preheated air that boosts boiler and process efficiency. The plate air preheater uses a counterflow arrangement, where flue gas and air move in opposite directions across pressed steel plates. This design maximizes heat transfer efficiency and supports flue gas heat recovery. Compared to traditional tubular air preheaters, plate air preheaters offer higher thermal performance, a smaller footprint, and longer service life.

Plate air preheaters rely on conduction to move sensible heat from flue gases to cold air. The solid plates separate the two streams, preventing contamination and minimizing leakage. Preheated air improves combustion, reduces fuel consumption, and supports sustainability goals in industries such as oil and gas, chemical, and metallurgy.

Feature | Plate Air Preheater | Tubular Air Preheater |

Structure | Multi-layer pressed steel plates in rectangular bundles | Thin-walled steel pipes arranged vertically |

Flow Pattern | Counterflow between flue gas and air | Flue gas passes along tubes; air passes horizontally |

Heat Transfer Efficiency | High | Low |

Footprint | Small | Large |

Corrosion Resistance | Less corrosion | More prone to corrosion |

Service Life | Long | Shorter |

Cost-effectiveness | Higher | Lower |

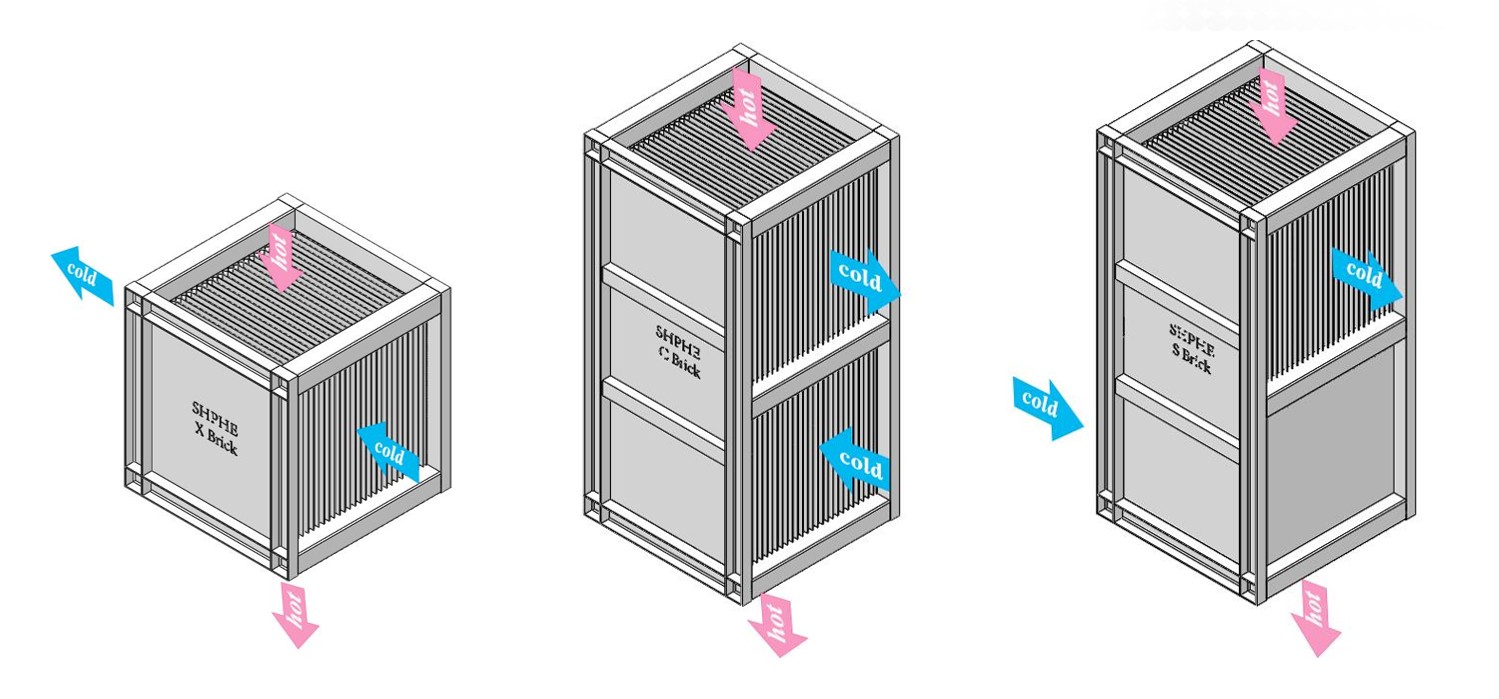

Plate Type Air Preheater Design

SHPHE engineers plate type air preheaters with modular construction and welded plates. These features allow easy installation, expansion, and maintenance. Welded plates eliminate the need for gaskets, making the heat exchanger suitable for high-pressure and high-temperature applications. The vertical placement of modules ensures optimal flow and efficient cleaning. SHPHE’s HT-Bloc Welded Plate Heat Exchanger and TP Welded Plate Heat Exchanger serve diverse industries, including petrochemical, power, and food processing.

Fully welded plate packs resist corrosion and handle aggressive fluids.

Compact counterflow designs maximize heat recovery and maintain a small footprint.

Staging options allow air to pass multiple times across the plates, increasing heat transfer efficiency.

Modular blocks can be added to expand capacity without major redesign.

Preheated air from these systems supports reliable operation and energy savings. SHPHE’s advanced plate air preheater designs deliver robust performance and adaptability for demanding industrial environments.

Efficiency Benefits of Air Preheaters

Energy Savings

Air preheaters deliver substantial energy savings across industrial sectors. Facilities in power generation, cement, chemical, and steel manufacturing use plate air preheaters to recover waste heat from flue gases. This recovery process preheats combustion air, which raises its temperature before entering boilers or furnaces. Preheated air improves combustion efficiency, reducing the need for additional fuel to reach optimal operating temperatures. Industries report fuel savings of approximately 20-25% after installing air preheaters, which translates into significant operational cost reductions. In cement production, preheated air enhances kiln thermal efficiency, cutting fuel consumption. Steel manufacturers benefit from improved blast furnace combustion, leading to better fuel utilization and lower emissions. These savings support energy conservation and emission reduction goals while optimizing resource use.

SHPHE integrates the "Smart Eye" digital monitoring system into its plate air preheater solutions. This system uses artificial intelligence and edge computing to monitor performance, ensuring maximum efficiency throughout the lifecycle. Operators receive real-time data for predictive maintenance, which helps maintain stable operation and energy efficiency.

Emissions Reduction

Air preheaters play a critical role in reducing industrial emissions. By recovering heat and delivering preheated air to combustion processes, these systems lower fuel consumption and decrease greenhouse gas output. Enhanced combustion efficiency means less fuel is burned for the same energy output, directly supporting sustainability initiatives. Facilities in oil and gas, chemical, and metallurgy industries rely on air preheaters to meet strict environmental standards. The use of compact plate type air preheaters further supports energy conservation and emission reduction by minimizing energy waste and maximizing heat transfer efficiency.

Benefit | Description |

Lower Fuel Consumption | Reduces CO₂ and NOx emissions |

Efficient Combustion | Optimizes fuel use, minimizing pollutants |

Waste Heat Recovery | Converts exhaust heat into useful energy, supporting sustainability efforts |

Compactness and Durability

Compact plate type air preheaters offer a small footprint and high heat transfer efficiency, making them ideal for facilities with limited space. SHPHE designs these systems using stainless steel and advanced materials, which provide long service life and superior corrosion resistance. The modular assembly allows for easy installation and maintenance, supporting continuous high-load operation. Unlike other types, plate air preheaters do not suffer from common failures such as tube explosions or vacuum decreases. Maintenance time is only 10% to 20% of that required for heat pipe air preheaters, which ensures reliable performance and economic benefits.

Plate air preheaters use high-grade materials for heat exchange elements, extending service life.

The design prevents air leakage and dust accumulation, improving durability.

Maintenance requirements remain low, supporting uninterrupted operation.

Compact structure reduces metal consumption and installation costs.

SHPHE’s plate air preheaters hold certifications such as ISO9001, ISO14001, OHSAS18001, and ASME U, confirming compliance with international standards. These certifications ensure quality and reliability for global applications in oil and gas, chemical, metallurgy, and other industries. SHPHE’s products meet the demands of international projects, providing robust solutions for energy efficiency and sustainability.

Choosing a Suitable Air Preheater

Application Scenarios

Selecting a suitable air preheater requires careful evaluation of process requirements and site conditions. Engineers consider factors such as heat duty, flow rates, operating temperatures, and available space. The following table summarizes key selection criteria:

Factor | Explanation |

Fouling tendencies | Plate models suit clean gases; tube types handle dirty gases better. |

Permissible pressure drop | Both types can achieve low drops; tube preferred for minimal pressure loss. |

Smoke outlet temperature | Materials must resist acid corrosion below dew point. |

Available space | Plate air preheaters offer compactness and larger heat exchange surfaces. |

Flow rates and temperatures | Directly impact heat transfer efficiency and design. |

Material and structure | Must match temperature, corrosion resistance, and thermal shock needs. |

Flow channel configuration | Adaptable to project-specific requirements. |

Compatibility | Must integrate with existing systems. |

Customization | Flexible design options for unique industrial processes. |

SHPHE customizes air preheaters for diverse industries, including oil and gas, chemical, and metallurgy. Common applications include hydrogen reforming furnaces, blast furnaces, and tail gas recovery units. Modular and retrofit options allow seamless integration into existing plants, even in space-constrained environments.

Maintenance and Reliability

Long service life and reliable operation depend on robust maintenance practices. SHPHE designs air preheaters with good corrosion resistance, using advanced materials and protective coatings. Operators prevent scaling by treating fluids and applying corrosion inhibitors. Regular inspections, cleaning, and component replacements maintain efficiency. The "Smart Eye" digital monitoring system enables predictive maintenance, energy efficiency diagnosis, and cleaning effect evaluation. Low air leakage, achieved through advanced seal designs, preserves heat transfer performance and reduces operational costs. These features ensure sustained efficiency and safety in harsh industrial conditions.

SHPHE’s plate solutions deliver energy savings, environmental protection, and long-term reliability for industrial facilities.

Modular, flexible designs adapt to diverse processes.

AIR FILMTM technology prevents corrosion, ensuring durability.

Facility managers can assess suitability through performance testing. Contact SHPHE by phone, email, or their website to explore tailored solutions.

FAQs

What industries benefit most from plate air preheaters?

Oil and gas, chemical, metallurgy, power generation, and food processing industries see the greatest efficiency gains from plate air preheaters.

How does SHPHE ensure product reliability?

SHPHE uses advanced materials, modular designs, and the "Smart Eye" digital monitoring system to maintain consistent performance and long service life.

Can SHPHE customize air preheaters for unique applications?

Yes, SHPHE offers tailored solutions for specific process requirements, including modular and retrofit options for challenging industrial environments.