How plate heat exchangers transform waste heat into usable energy

Plate Heat Exchanger: Design and Working Principle

A plate heat exchanger recovers waste heat by moving thermal energy from a hot process stream to a cooler one. This transfer allows facilities to use energy that would otherwise go unused. As a result, companies reduce energy loss, lower costs, and support environmentally friendly operations.

Efficient heat recovery leads to significant operational savings.

Basic Structure and Function

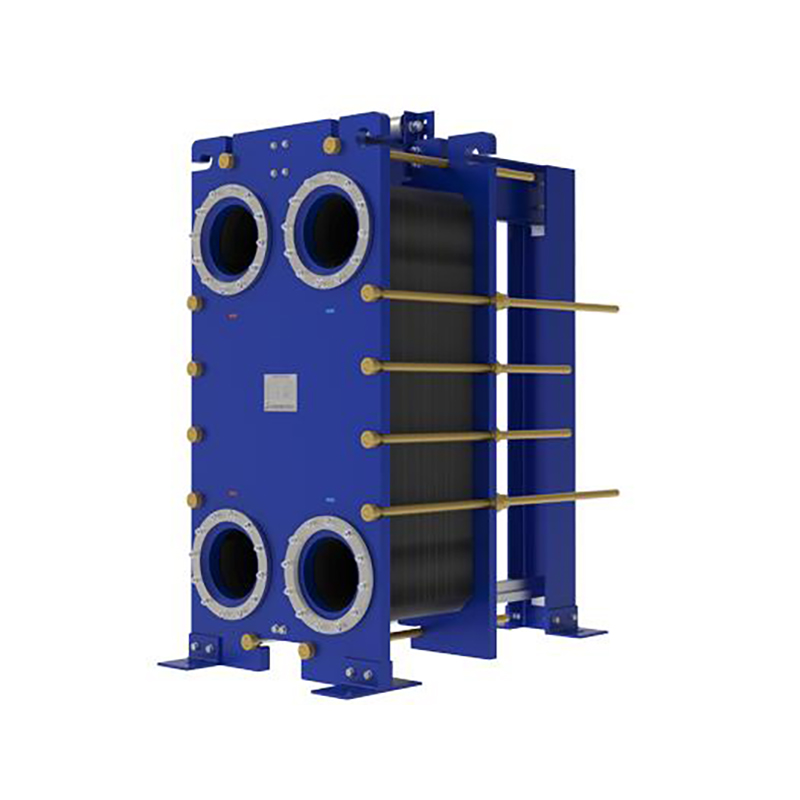

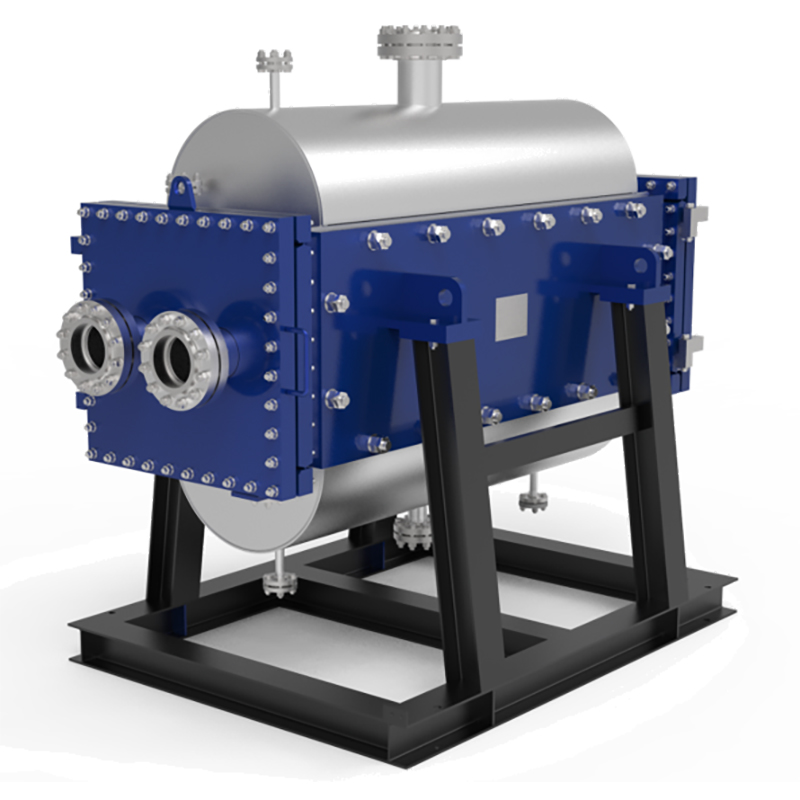

A plate heat exchanger uses a series of thin, corrugated metal plates to transfer heat between two fluids. Each plate creates a narrow channel, allowing fluids to flow on either side. The plates stack together, forming a compact unit. Gaskets or seals keep the fluids separate and direct their paths through the exchanger.

The design maximizes surface area, which improves heat transfer efficiency. The fluids flow in opposite directions, a setup called counterflow. This arrangement helps the plate heat exchanger recover more energy from the waste stream..

Operation in Industrial Applications

Industries rely on plate heat exchangers for many processes. Chemical plants use them to recover heat from hot process streams. Food and beverage factories depend on them to pasteurize liquids and reclaim energy. Power plants often install these exchangers to cool machinery and reuse waste heat.

A typical operation involves two separate fluid circuits. The hot fluid releases energy as it passes through the exchanger. The cooler fluid absorbs this energy, raising its temperature. This process reduces fuel consumption and lowers emissions.

Engineers value plate heat exchangers for their flexibility, easy maintenance, and high efficiency. These features make them a preferred choice in modern industrial systems.

Plate Heat Exchanger: Capturing Waste Heat and Delivering Benefits

Mechanisms of Heat Recovery and Transfer

A plate heat exchanger captures waste heat by allowing two fluids to flow on opposite sides of thin metal plates. The hot fluid releases energy as it moves through the channels. The cold fluid absorbs this energy on the other side. This direct contact with a large surface area speeds up the transfer process.

Engineers design the plates with special patterns. These patterns create turbulence in the fluids. Turbulence increases the rate of heat transfer. The counterflow arrangement, where fluids move in opposite directions, helps the system recover more energy from the waste stream.

Efficiency, Compactness, and Adaptability

Plate heat exchangers offer several advantages in industrial settings. Their compact design saves valuable floor space. Facilities can install them in tight areas where other systems would not fit. The modular structure allows operators to add or remove plates to match changing process needs.

A plate heat exchanger operates with high thermal efficiency. The thin plates and close spacing maximize the contact area between fluids. This design reduces the temperature difference needed for effective heat transfer. As a result, the system recovers more waste heat and lowers energy consumption.

The adaptability of these exchangers stands out. Operators can easily clean or service the unit by removing the plates. This feature reduces downtime and maintenance costs. The system handles a wide range of fluids, temperatures, and pressures, making it suitable for many industries.

| Feature | Benefit |

|---|---|

| Compact size | Saves space |

| Modular design | Easy to expand or modify |

| High efficiency | Maximizes heat recovery |

| Easy maintenance | Reduces downtime |

| Versatility | Handles various applications |

Real-World Benefits and Industry Examples

Many industries use plate heat exchangers to turn waste heat into usable energy. Chemical plants recover heat from hot process streams and use it to preheat raw materials. Food and beverage factories reclaim energy during pasteurization and cleaning processes. Power plants use these exchangers to cool equipment and reuse the captured heat elsewhere in the facility.

In a dairy processing plant, engineers installed a plate heat exchanger to recover heat from pasteurized milk. The recovered energy now preheats incoming raw milk, cutting fuel costs and reducing emissions.

Operators in the pharmaceutical industry rely on these systems to maintain precise temperature control. Breweries use them to cool wort quickly and reuse the heat for other steps in production. These examples show how a plate heat exchanger delivers both economic and environmental benefits.

Plate heat exchanger technology helps industries recover waste heat and convert it into usable energy. Companies improve efficiency and support sustainability.

·Facilities reduce costs

·Operations become more environmentally responsible

Plate heat exchangers play a vital role in modern energy management.

FAQ

How does a plate heat exchanger improve energy efficiency?

Plate heat exchangers recover waste heat quickly. They transfer thermal energy to other process streams. Facilities reduce fuel usage and lower operational costs.

What maintenance does a plate heat exchanger require?

Operators inspect plates for fouling. They clean surfaces regularly. Gaskets need replacement when worn.

·Cleaning frequency depends on fluid type

·Routine checks prevent downtime

Can plate heat exchangers handle different fluids?

| Fluid Type | Suitability |

|---|---|

| Water | Excellent |

| Oil | Good |

| Chemicals | Varies |

Engineers select materials based on fluid compatibility and temperature requirements.