How Standard Heat Exchangers Drive Industrial Performance

Efficient thermal management unlocks higher industrial performance. A standard exchange heat exchanger is essential for optimizing energy, reducing costs, and boosting reliability. With industrial waste heat potential in the EU and UK estimated at 221.32 TWh/year, proper implementation of a standard exchange heat exchanger directly improves process stability and strengthens the bottom line.

What Is a Standard Heat Exchanger and How Does It Work?

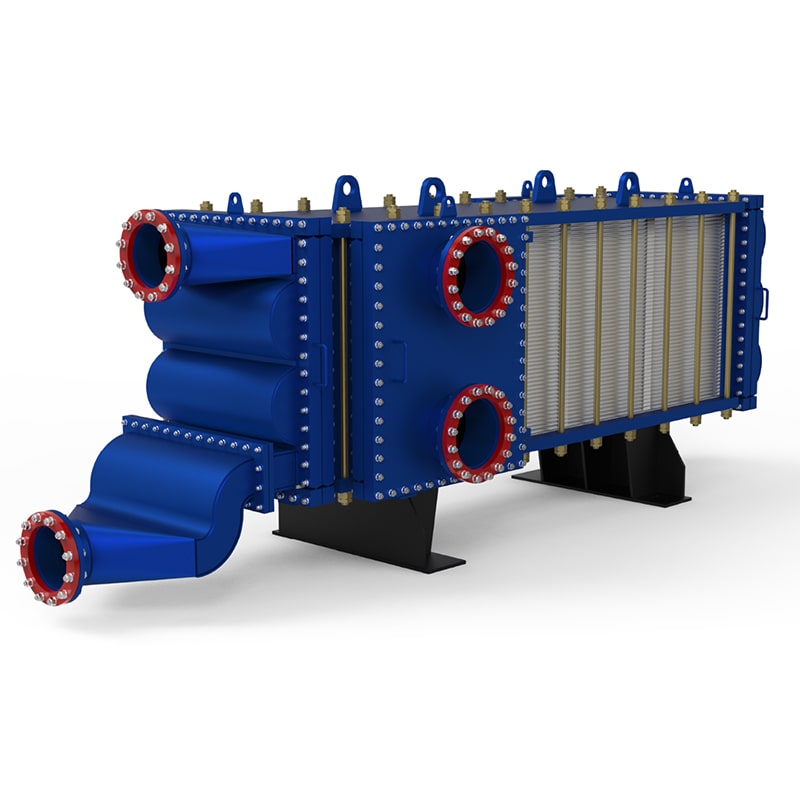

A standard heat exchanger is a device engineered to transfer thermal energy from one fluid to another without allowing them to mix. Its operation relies on fundamental thermodynamic principles to manage process temperatures efficiently.

The Core Principle of Efficient Heat Transfer

Heat transfer is governed by the laws of thermodynamics. The First Law states that energy is always conserved, while the Second Law dictates that heat naturally flows from a hotter substance to a colder one. A heat exchanger facilitates this natural flow. This process occurs through three primary mechanisms:

·Conduction: Heat moves through direct physical contact.

·Convection: Heat travels through the movement of fluids (liquids or gases).

·Radiation: Heat is transferred via electromagnetic waves.

Inside the exchanger, a conductive barrier, such as a metal plate or tube wall, separates the two fluids. The system maximizes surface area to accelerate the transfer, allowing one fluid to heat up while the other cools down in a controlled and continuous cycle.

Its Role in Heating and Cooling Industrial Processes

In industrial settings, a standard exchange heat exchanger performs the critical functions of heating and cooling. Precise temperature control is essential for process efficiency, product quality, and operational safety. For heating applications, the device uses a hot medium like steam or thermal oil to raise the temperature of a process fluid. Common examples include:

·Heating fluids for jacketed vessels, tanks, and reactors

·Powering equipment such as dryers, extruders, and ovens

·Preheating liquids and gases for subsequent process stages

Conversely, the exchanger also removes excess heat. It uses a coolant like water or air to lower the temperature of hot process fluids, preventing equipment overheating and ensuring stable operating conditions. This dual capability makes it an indispensable tool for thermal management across countless industries.

Key Types of Standard Heat Exchangers in Industry

Industries rely on several types of standard heat exchangers to meet diverse thermal management needs. Each design offers unique advantages for specific applications, from heavy-duty processing to precision cooling. Understanding these key types helps in selecting the right equipment for optimal performance.

Shell-and-Tube Heat Exchangers

The shell-and-tube heat exchanger is a workhorse in heavy industries like oil and gas. Its robust construction, often using materials like carbon steel or stainless steel, makes it ideal for high-pressure and high-temperature services. This design follows strict TEMA standards for reliability. Common applications include:

·Preheating crude oil before the refining process.

·Cooling and condensing gas back into a liquid state.

·Serving critical functions in petrochemical plants and refineries.

Plate-and-Frame Heat Exchangers

A plate-and-frame heat exchanger offers high thermal efficiency in a compact footprint. This design uses a series of corrugated plates to create turbulent flow, maximizing heat transfer. Its modular nature allows for easy cleaning and scalability, making it a preferred choice in the food and beverage industry for applications like milk processing and bakery chilling. The small size of this standard exchange heat exchanger saves valuable plant space while delivering superior performance.

Air-Cooled Heat Exchangers

Air-cooled heat exchangers provide a reliable cooling solution by using ambient air instead of water. This makes them essential in water-scarce regions and environmentally sensitive operations. They are widely used across demanding sectors such as power generation, petrochemicals, and oil & gas. Key benefits include significant water conservation, reduced operating costs, and enhanced operational safety by eliminating water-related hazards.

How a Standard Exchange Heat Exchanger Boosts Performance

A standard heat exchanger is more than just a piece of equipment; it is a strategic asset that directly enhances industrial performance. Its implementation drives improvements across three critical areas: energy consumption, process stability, and equipment longevity. By optimizing thermal management, facilities unlock significant operational and financial advantages.

Enhancing Energy Efficiency and Reducing Costs

One of the most immediate impacts of a heat exchanger is its ability to slash energy consumption. Industrial processes generate vast amounts of waste heat. Instead of venting this valuable thermal energy into the atmosphere, a heat exchanger captures and repurposes it. This recycled energy can preheat incoming fluids, reducing the fuel or electricity needed for primary heating systems. This direct energy recovery translates into substantial cost savings.

High-efficiency models can deliver remarkable returns, making them a wise capital investment. The potential for savings is often significant, with a rapid payback period.

| Metric | Value |

|---|---|

| Energy Savings | Up to 70% |

| Payback Period | ~2 years |

A real-world retrofit project illustrates these savings powerfully. By upgrading the primary and secondary heat exchangers on a catalytic oxidizer, one facility achieved transformative results.

Before Retrofit: The oxidizer needed up to six hours to warm up, costing the plant approximately $266 per startup.

After Retrofit: The warm-up time shrank to just one hour.

Cost Savings: The company saved around $230 per startup, accumulating up to $30,000 in annual operating cost reductions.

Additional Benefits: The upgrade also reduced plant downtime and increased worker production.

Improving Process Control and Product Quality

Precise temperature control is fundamental to achieving consistent product quality. Many industrial processes, especially chemical reactions, operate optimally only within very narrow temperature windows. A heat exchanger provides the mechanism to maintain these exact conditions.

For exothermic reactions that generate heat, the exchanger safely removes excess thermal energy, preventing dangerous runaway reactions and product degradation. For endothermic reactions that require heat, it supplies energy at a controlled rate. This stability is crucial for maximizing reaction yields and minimizing the formation of unwanted byproducts.

Chemical reactions operate most efficiently within specific temperature ranges. Excessive heat can lead to uncontrolled reactions or equipment damage, while insufficient heat can result in incomplete reactions and lower yields. Maintaining this ideal temperature balance is crucial for ensuring product quality, especially with heat-sensitive materials.

This principle extends beyond chemical plants to advanced manufacturing, where thermal management directly impacts the final product's integrity and performance.

·EV Batteries: Optimized thermal control ensures the consistent application of thermal interface materials (TIMs), improving battery performance and extending its lifespan.

·Electronics: Steady temperatures during assembly prevent sensitive components from warping or suffering damage, reducing defects.

·General Manufacturing: Enhanced thermal adaptability during production leads to more robust and reliable end products.

Increasing Operational Uptime and Reliability

Equipment failure is a primary cause of costly, unplanned downtime. Inadequate temperature control is a major contributor to premature mechanical failure. A standard exchange heat exchanger acts as a critical safeguard, protecting both itself and connected machinery from the damaging effects of thermal stress.

Operating equipment outside its recommended temperature range leads to a cascade of problems.

·Overheating: Causes thermal degradation of materials, insulation breakdown, and accelerated lubricant failure, leading to increased friction and wear.

·Thermal Shock: Rapid temperature swings can cause materials to crack or suffer brittle failure.

·System Strain: Uncontrolled temperatures force pumps, compressors, and other machinery to work harder, consuming more energy and failing faster.

Proper maintenance of the heat exchanger is vital for ensuring it protects the entire system. Regular cleaning prevents fouling and corrosion, which would otherwise reduce efficiency and force connected machinery to compensate. By maintaining the heat exchanger at peak performance, operators reduce stress across the entire process line. This proactive approach prevents minor issues from escalating into catastrophic failures, leading to fewer breakdowns, a longer operational lifecycle for all machinery, and maximized uptime.

The Strategic Advantages of Using Heat Exchangers

Beyond day-to-day operations, heat exchangers offer significant strategic advantages that strengthen a company's competitive edge. They provide precise process control, create value from waste streams, and support critical sustainability initiatives. Integrating this technology is a forward-thinking move that pays dividends in efficiency, cost savings, and corporate responsibility.

Achieving Precise Temperature Management

Maintaining exact temperatures is crucial for industrial success. A standard exchange heat exchanger provides this precision through a combination of smart design and advanced control technologies. These systems ensure processes operate within their optimal thermal window, safeguarding product quality and consistency. Key technologies that enable this control include:

·Temperature Sensors: These devices monitor conditions in real-time, feeding critical data to controllers.

·Automated Controllers: They use sensor input to regulate fluid flow rates, keeping temperatures within specified ranges.

·Variable Flow Systems: These systems adjust fluid flow to match changing load requirements, optimizing energy use.

·Proper Sizing: A correctly sized heat exchanger ensures the ideal temperature differential for efficient thermal transfer.

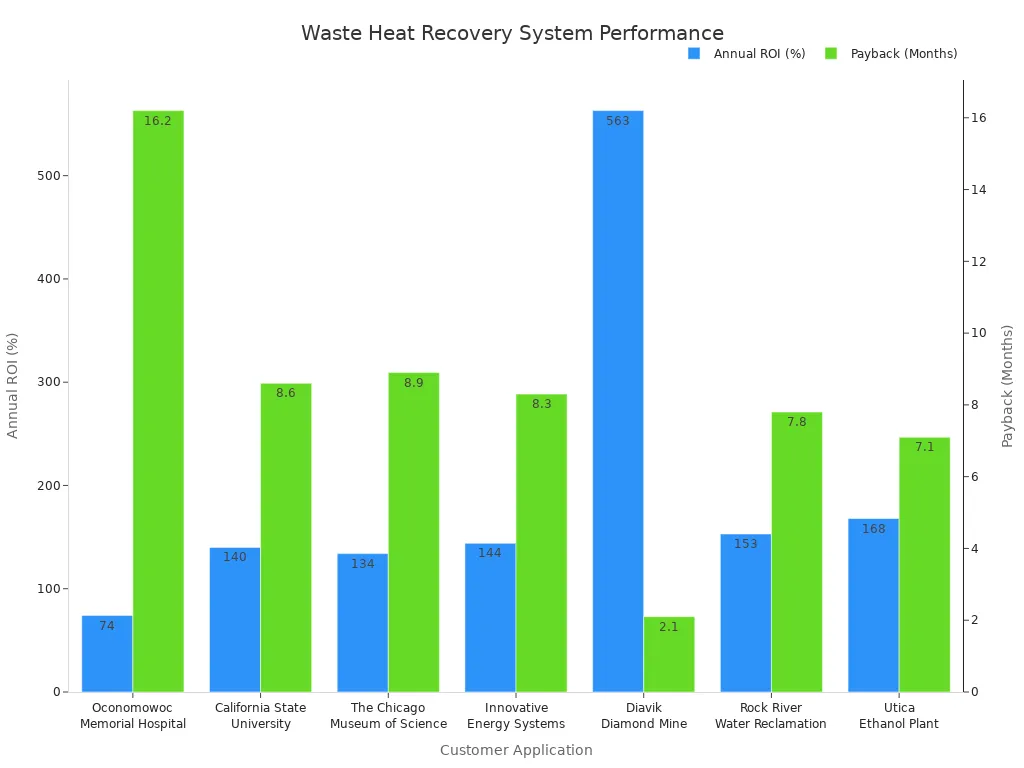

Capturing and Reusing Waste Heat

Industrial processes often generate enormous amounts of thermal energy that is simply lost to the atmosphere. Heat exchangers capture this valuable waste heat and repurpose it elsewhere in the facility. This waste heat recovery directly reduces the need for primary energy sources, leading to dramatic fuel savings and a strong return on investment. Case studies from various industries demonstrate rapid payback periods, often in less than a year.

Supporting Environmental and Sustainability Goals

By recovering waste heat, facilities significantly lower their energy consumption. This reduction directly translates to a smaller carbon footprint, as less fuel is burned and fewer greenhouse gases are emitted. Heat exchangers also contribute to water conservation. Air-cooled models, for example, eliminate the need for water in cooling processes, a critical advantage in water-scarce regions. Adopting this technology helps companies meet and exceed environmental regulations, strengthening their brand reputation as sustainable industry leaders.

Maximizing Performance: Selection and Maintenance

Achieving optimal performance from a standard heat exchanger requires careful selection and diligent upkeep. These two pillars ensure long-term efficiency, reliability, and return on investment.

Choosing the Right Heat Exchanger for Your Needs

Selecting the right heat exchanger is the foundation of efficient thermal management. A successful choice depends on a thorough analysis of process requirements. Key factors include:

·Operational design parameters like temperatures and pressures

·Fluid compatibility and required approach temperatures

·Available space allocation or equipment footprint

·Volumetric and mass flow rates

·Overall project budget

Material selection is especially critical when dealing with different fluid types. The chemical properties of fluids, such as pH levels and the presence of chlorides, directly influence corrosion rates. The choice of material must align with the application's demands to ensure longevity.

| Application Type | Key Selection Criteria | Material Examples |

|---|---|---|

| Corrosive Fluids | High corrosion resistance | Titanium, Hastelloy |

| Moderate Applications | Balanced performance and cost | Stainless steel (316L) |

| Non-Corrosive Fluids | Economic factors | Carbon steel, 304L Stainless |

The Importance of Regular Maintenance

Consistent maintenance preserves the performance and extends the life of a heat exchanger. Over time, internal surfaces can develop buildup, a condition known as fouling. Operators should watch for clear warning signs.

Common signs of fouling include reduced heat transfer efficiency, an elevated pressure drop across the unit, fluctuating outlet temperatures, and decreased flow rates.

A proactive maintenance plan prevents these issues from escalating. A structured approach ensures equipment remains in peak condition.

1.Schedule Routine Maintenance: Plan downtime during low-production periods and order necessary parts in advance.

2.Inspect for Fouling: Regularly check for signs of buildup, scaling, or sediment on both the tube and shell sides.

3.Monitor Heat Transfer Fluid: Test fluid samples periodically to assess their condition and prevent system degradation.

4.Follow Post-Cleaning Procedures: After cleaning, thoroughly rinse out chemicals, inspect gaskets, and document all actions.

Standard heat exchangers are vital assets driving industrial performance through superior energy efficiency, process control, and operational reliability. By repurposing thermal energy, they deliver direct cost savings and fuel a global market projected to exceed USD 32 billion. Evaluating processes for upgrades is a critical step toward achieving significant performance gains.

FAQ

What is the primary benefit of a standard heat exchanger?

It captures and reuses waste heat to lower energy consumption and operational costs. This process boosts overall plant efficiency and provides a strong return on investment.

Can a standard model fit specific industry needs?

Yes, standard models offer high adaptability. A full range of types, including gasketed, welded, and brazed, exists to precisely match diverse requirements across many industries.

How often should a heat exchanger be inspected?

Operators should perform regular inspections for fouling signs like reduced efficiency or pressure drop. A proactive maintenance schedule ensures optimal performance and prevents unexpected downtime.