News

Find by news

Essential Guide to Maintaining Wide Gap Heat Exchangers in Sugar Plants

Maintain sugar juice heater wide gap exchangers in sugar plants for efficient operation, reduced fouling, and consistent product quality.

Jan-30-2026

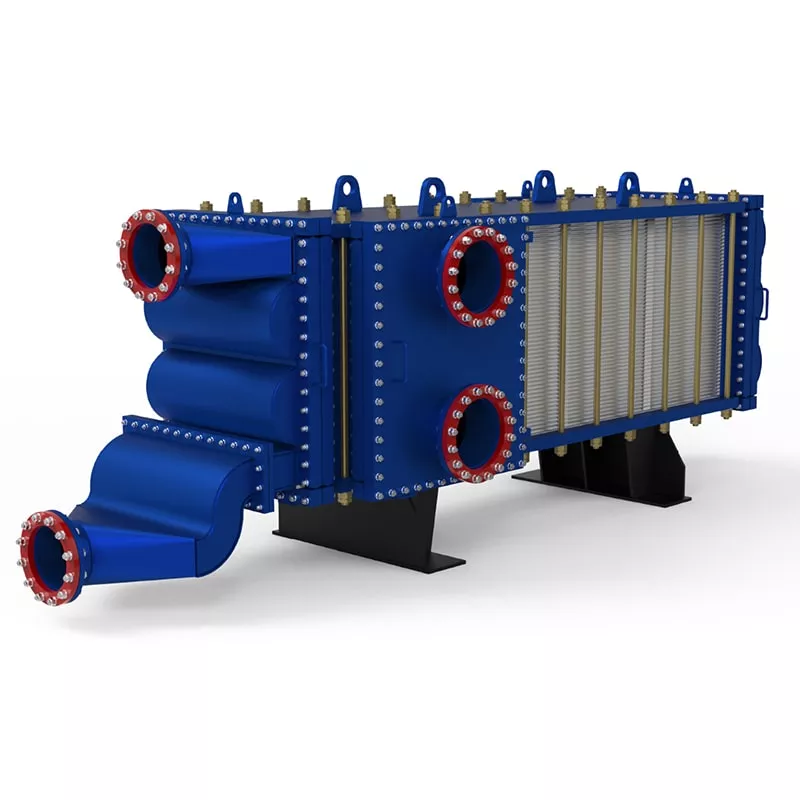

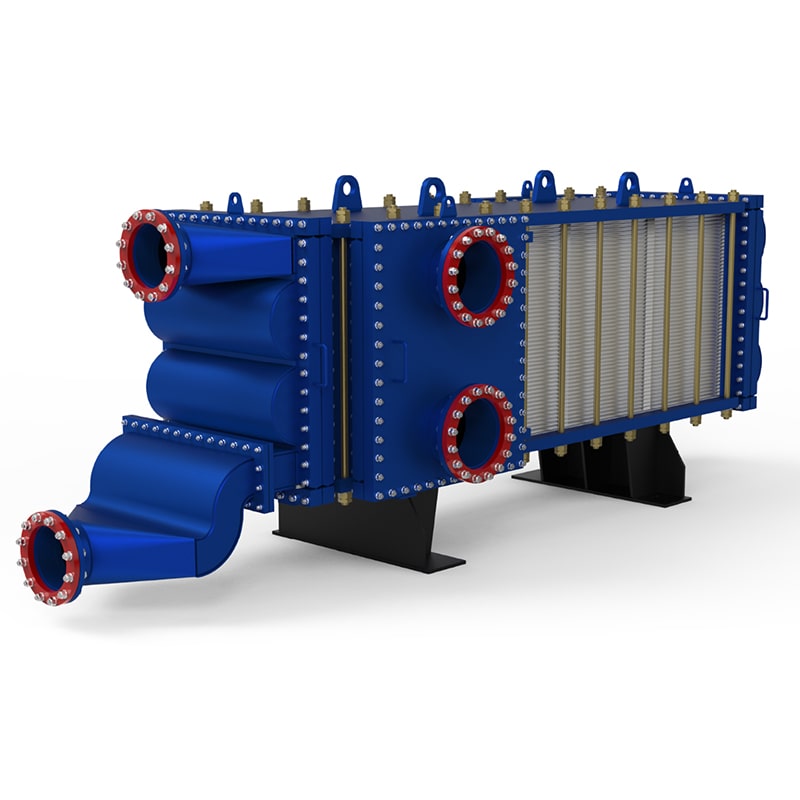

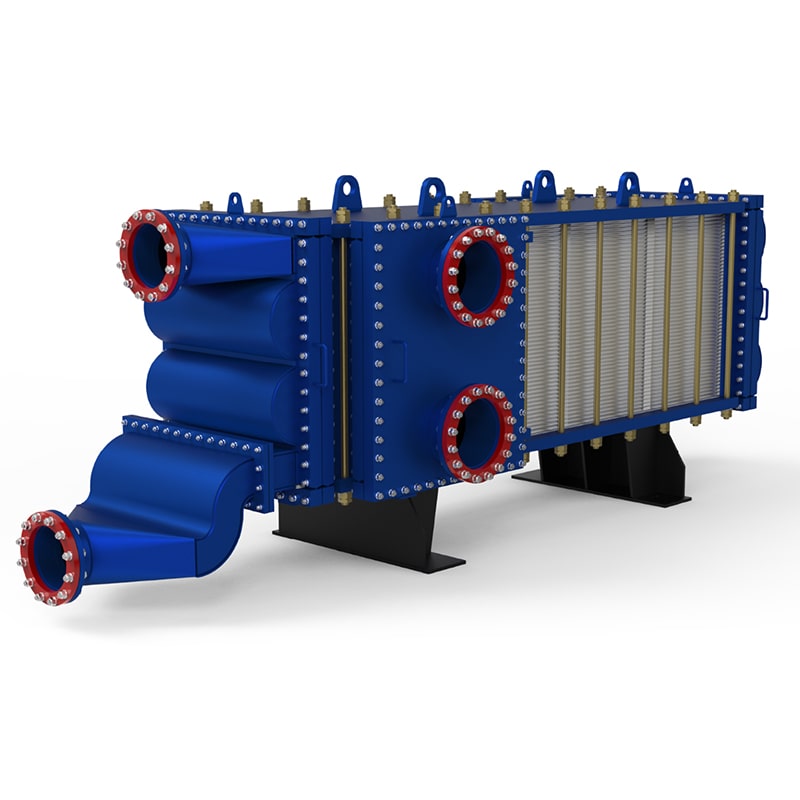

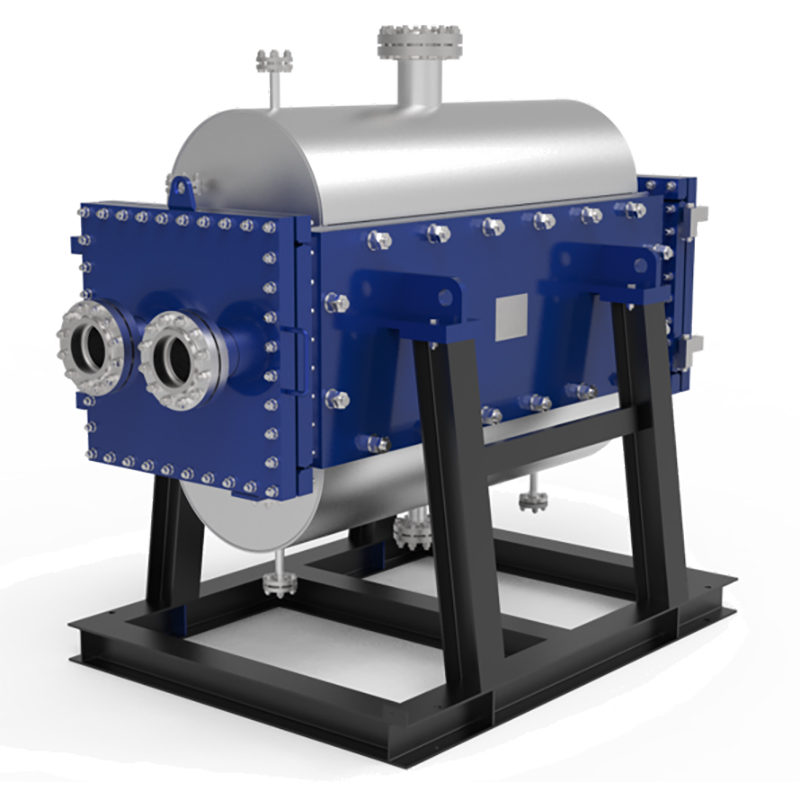

Spiral vs Shell-and-Tube vs Plate Heat Exchangers for Slurry Applications

Compare spiral, shell-and-tube, and plate slurry heat exchangers for fouling resistance, efficiency, and maintenance to choose the best fit for your application.

Jan-28-2026

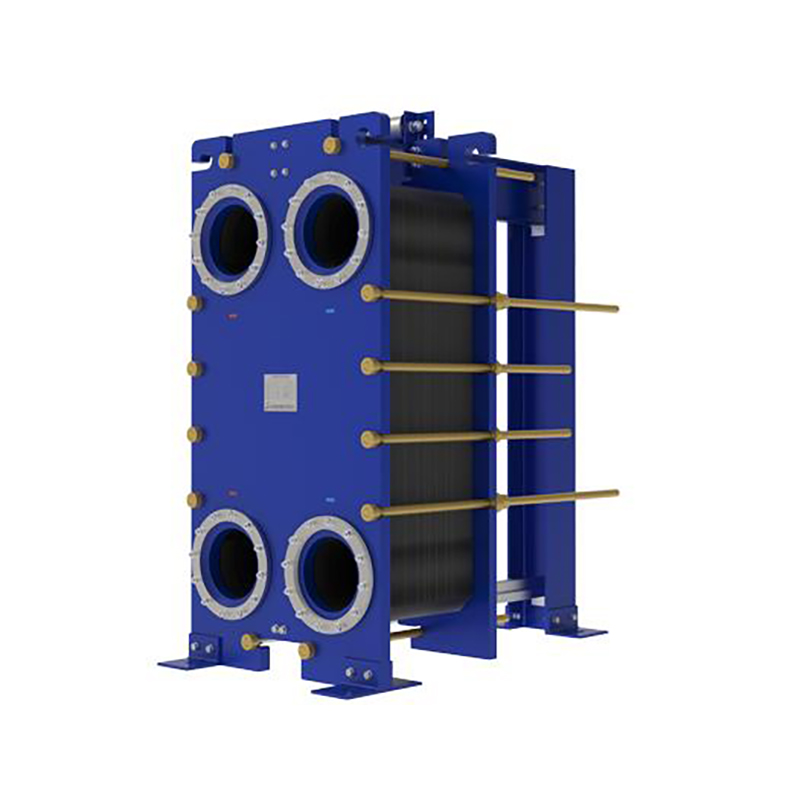

Top Reasons to Pick Plate and Frame Heat Exchangers Over Shell and Tube

Plate and frame heat exchangers offer higher efficiency, easier cleaning, and a compact footprint compared to shell and tube heat exchangers.

Jan-27-2026

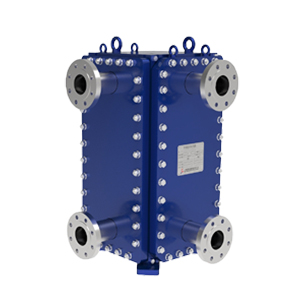

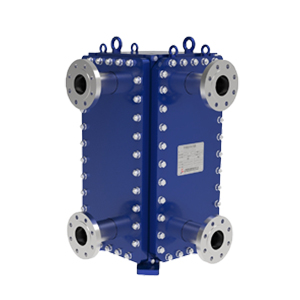

Top Gasket Free Heat Exchanger Models for Industrial Use

Compare top gasket free heat exchanger models for 2026, including Shanghai Heat Transfer, Alfa Laval, and more, for reliable industrial performance.

Jan-26-2026

Leakage free air preheater picks that stop waste now

Leakage free air preheater solutions from top brands cut energy waste, lower emissions, and ensure reliable, leak-proof performance for industrial systems.

Jan-23-2026

Printed Circuit Heat Exchanger Innovations Driving Sustainability

Printed circuit heat exchanger advancements in 2026 boost energy efficiency, sustainability, and industrial performance with smart, compact designs.

Jan-22-2026

Best Selling Plate Heat Exchangers for HVAC Applications

Compare top HVAC plate heat exchanger brands and models for efficient, reliable climate control. Find the best options for your heating and cooling needs.

Jan-21-2026

Why Choose 316L Stainless Steel for Your Heat Exchanger

Stainless steel 316L heat exchanger offers superior corrosion resistance, durability, and low maintenance, making it ideal for demanding industrial use.

Jan-20-2026

Easy Maintenance Tips for Gas Plate Heat Exchangers

Install and maintain your gas plate heat exchanger with safety tips, cleaning steps, and troubleshooting advice for long-lasting, efficient operation.

Jan-16-2026

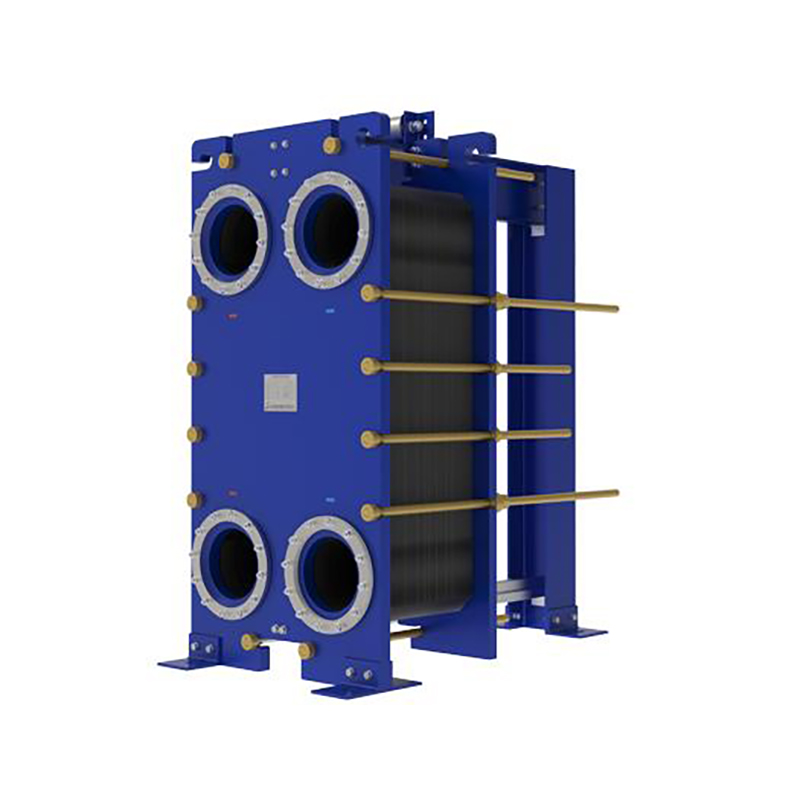

Fully Welded Heat Exchangers vs Gasketed Plate Heat Exchangers Which Is Right for Your Industry

Compare fully welded heat exchanger vs gasketed plate heat exchanger to choose the best fit for your industry’s durability, maintenance, and reliability needs.

Jan-15-2026

SHPHE has complete quality assurance system from design, manufacturing, inspection and delivery. It is certified with ISO9001, ISO14001, OHSAS18001 and hold ASME U Certificate.