5 key roles of plate heat exchanger gaskets.

Plate heat exchanger gaskets perform 5 key roles: ...

More

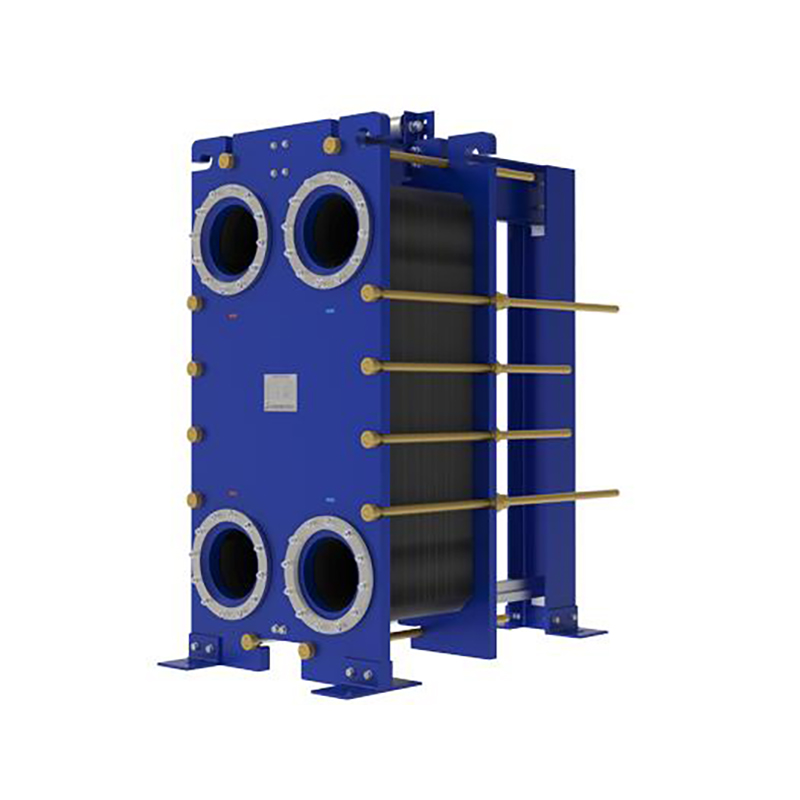

Liquid heat exchangers operate on the fundamental principle of transferring thermal energy between two or more liquid streams while keeping them physically separated. This process is governed by the laws of thermodynamics, primarily conduction and convection, and is facilitated by a solid barrier, typically a series of tubes, plates, or coils, which forms the heat transfer surface. The driving force for heat exchange is the temperature difference between the hot and cold fluids; heat naturally flows from the hotter medium to the cooler one. The efficiency of this transfer is quantified by the overall heat transfer coefficient (U-value), a measure of the total thermal resistance, which is influenced by the materials of construction, fluid properties, flow arrangement (counter-current, co-current, or cross-flow), and the velocity of the fluids. Counter-flow designs, where fluids move in opposite directions, are particularly efficient as they maintain a more consistent temperature gradient across the entire length of the exchanger, maximizing the log mean temperature difference (LMTD). The design is a precise engineering calculation balancing heat transfer rate, pressure drop, and physical size. Materials like stainless steel, titanium, or copper-nickel alloys are selected based on the fluids' corrosiveness and thermal conductivity requirements. Computational Fluid Dynamics (CFD) is extensively used to simulate and optimize the fluid dynamics and thermal performance, ensuring the design meets specific thermal duty and efficiency targets before manufacturing.

The principle dictates that effective heat exchange requires a large surface area relative to the exchanger's volume, leading to designs with intricate internal pathways. Plate heat exchangers, for instance, use corrugated plates to create turbulent flow, which enhances heat transfer coefficients and reduces fouling. In shell and tube exchangers, baffles are strategically placed to direct the shell-side fluid across tube bundles, improving heat transfer and providing structural support. The thermal design must also account for fouling factors—the accumulation of deposits on heat transfer surfaces—which insulate the surfaces and drastically reduce efficiency over time. To mitigate this, designs include fouling allowances or incorporate easy cleaning access. The operational principle is not merely about transferring heat but doing so in a controlled, predictable, and efficient manner, ensuring process stability, product quality, and energy conservation in systems ranging from power generation and chemical processing to HVAC and renewable energy applications.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Plate heat exchanger gaskets perform 5 key roles: ...

More

A gasket in heat exchanger seals surfaces, blocks ...

MoreAPI 662 defines standards for plate heat exchanger...

More

You can see clear differences between welded block...

More

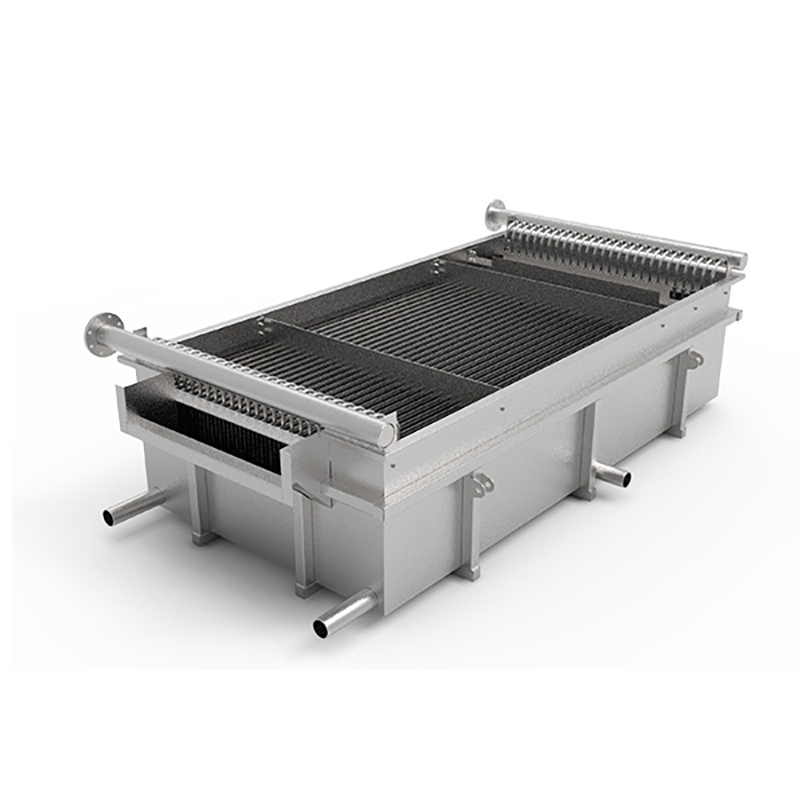

The dimple plate heat exchanger, also known as the...

More

Shanghai Heat Transfer stands out with its ISO9001...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

Michael Chen

Process EngineerThis liquid heat exchanger has been a game-changer for our chemical processing line. The thermal efficiency is outstanding, and it has significantly reduced our energy consumption. The build quality is robust and has required zero maintenance in the 6 months since installation. Highly recommended for demanding industrial applications.

Sarah Johnson

HVAC Systems DesignerWe specified this unit for a large commercial building's climate control system, and it has performed flawlessly. The compact design saved us crucial space in the mechanical room, and its ability to handle variable flow rates keeps the system running smoothly and efficiently. A superior product from a great manufacturer.

David Rodriguez

Maintenance ManagerExtremely reliable piece of equipment. It's been running 24/7 in our plant for over a year, transferring heat between our hydraulic oil cooling loop and process water. It's simple to clean and service, which is a huge plus for my team. Took off one star because the initial mounting brackets were a bit flimsy and needed reinforcing.

Emily Wang

R&D Lab DirectorPrecision and consistency are critical in our research, and this laboratory-scale liquid heat exchanger delivers both. The temperature control is exceptionally precise (±0.2°C), allowing for repeatable experiments. Its corrosion-resistant materials are perfect for handling our various coolant chemistries. An essential tool for our lab.