5 key roles of plate heat exchanger gaskets.

Plate heat exchanger gaskets perform 5 key roles: ...

More

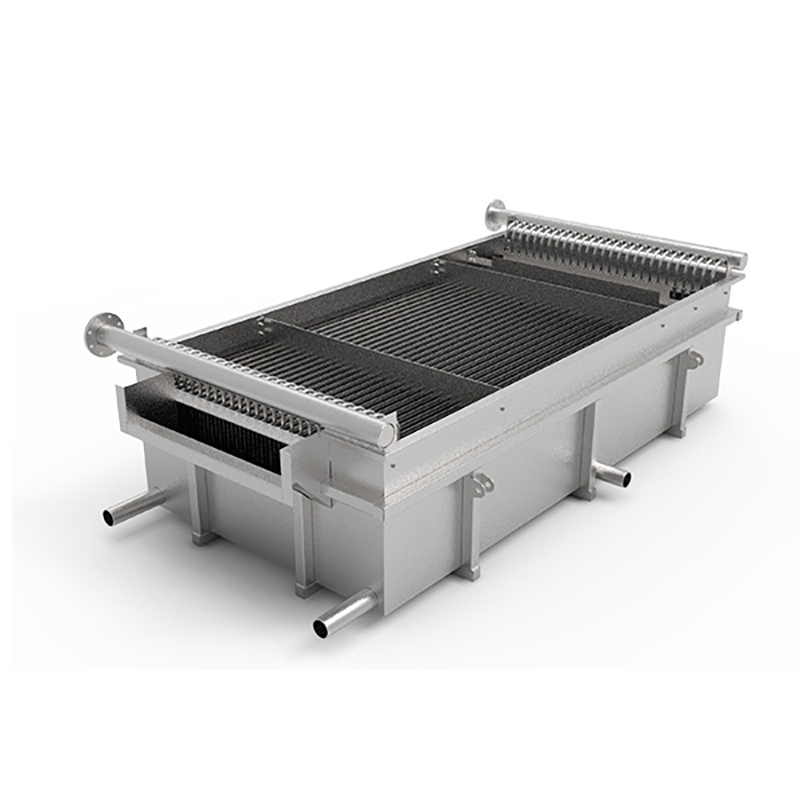

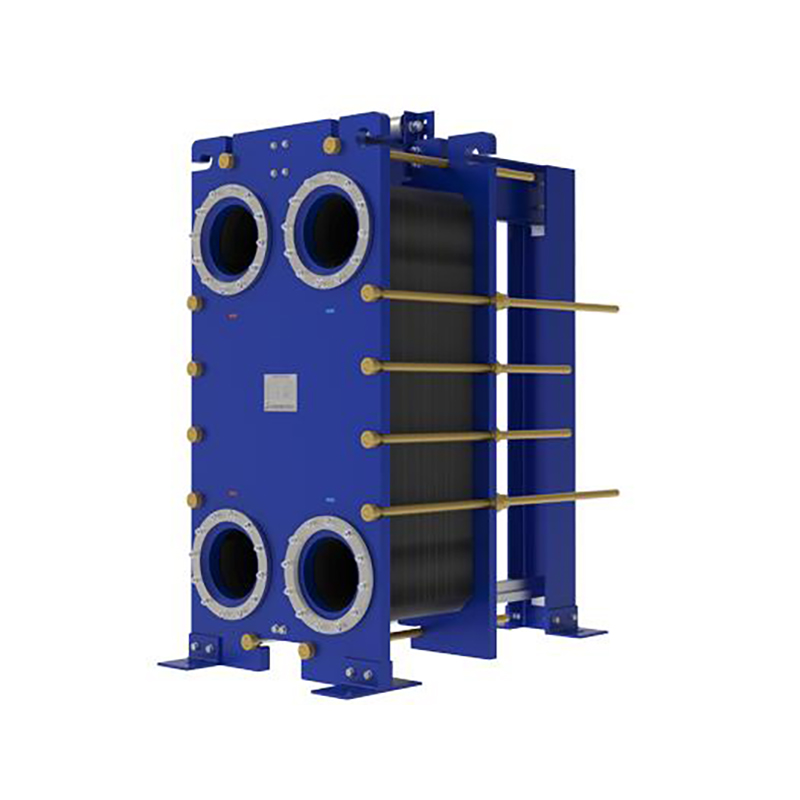

A liquid nitrogen heat exchanger is a specialized cryogenic device designed to transfer extreme cold from liquid nitrogen to another medium, such as a gas, liquid, or process stream, without direct contact. These systems are engineered to handle the ultra-low temperatures of liquid nitrogen, which boils at -196°C (-321°F), and are constructed from materials like stainless steel, copper, or aluminum that retain toughness and prevent brittleness at cryogenic levels. The core principle involves the latent heat of vaporization, where liquid nitrogen absorbs substantial energy as it changes phase from liquid to gas, providing intense cooling power. Common designs include shell-and-tube, plate-fin, and coil-wound configurations, each optimized for specific applications like rapid freezing, environmental simulation, or industrial gas cooling. They are critical in processes requiring precise temperature control and are integrated into systems where minimizing thermal loss and maximizing efficiency are paramount. Industries utilizing these exchangers range from food processing and pharmaceuticals to aerospace and electronics manufacturing, highlighting their versatility in handling extreme thermal transfer challenges.

Liquid nitrogen heat exchangers offer unparalleled cooling rates, capable of achieving temperatures as low as -196°C almost instantaneously, which is critical for applications like flash freezing in the food industry, where preserving cellular integrity and product quality is essential. Their high heat transfer efficiency, often exceeding 90% in well-designed systems, reduces nitrogen consumption and operational costs; for instance, industrial data shows optimized exchangers can lower LN2 usage by up to 30% compared to direct injection methods. They provide superior temperature uniformity and control, with precision within ±1°C in applications such as semiconductor testing or aerospace component conditioning, ensuring process reliability and repeatability. Safety is enhanced through non-contact designs that prevent contamination—vital in pharmaceutical or chemical processes—while robust construction minimizes risks of leaks or failures under thermal stress. Additionally, their scalability and adaptability to various pressures and flow rates make them ideal for diverse settings, from small labs to large-scale industrial plants, offering a sustainable solution by leveraging cryogenic by-products from air separation units.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Plate heat exchanger gaskets perform 5 key roles: ...

More

A gasket in heat exchanger seals surfaces, blocks ...

MoreAPI 662 defines standards for plate heat exchanger...

More

You can see clear differences between welded block...

More

The dimple plate heat exchanger, also known as the...

More

Shanghai Heat Transfer stands out with its ISO9001...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

Michael Chen

Cryogenic EngineerThis liquid nitrogen heat exchanger's efficiency is outstanding. It dropped our process cooling time by 40% and the build quality is incredibly robust. A critical piece of equipment that performs flawlessly.

Sarah Johnson

Lead Lab TechnicianPrecision temperature control is vital for our research. This heat exchanger maintains a stable -196°C with minimal fluctuation, which has significantly improved the reproducibility of our cryogenic experiments. Highly recommended for any biobanking application.

David Rodriguez

Food Processing Plant ManagerWe integrated this unit into our flash-freezing line. It's incredibly efficient, drastically reducing our nitrogen consumption. Lost one star only because the initial installation instructions could have been clearer, but the performance itself is top-notch.

Emily Watson

Materials ScientistExceptional performance in our superconductivity testing setup. The heat transfer rate is phenomenal, allowing for rapid and controlled cooling of samples. The safety features and durability make it well worth the investment for high-end R&D.