5 key roles of plate heat exchanger gaskets.

Plate heat exchanger gaskets perform 5 key roles: ...

More

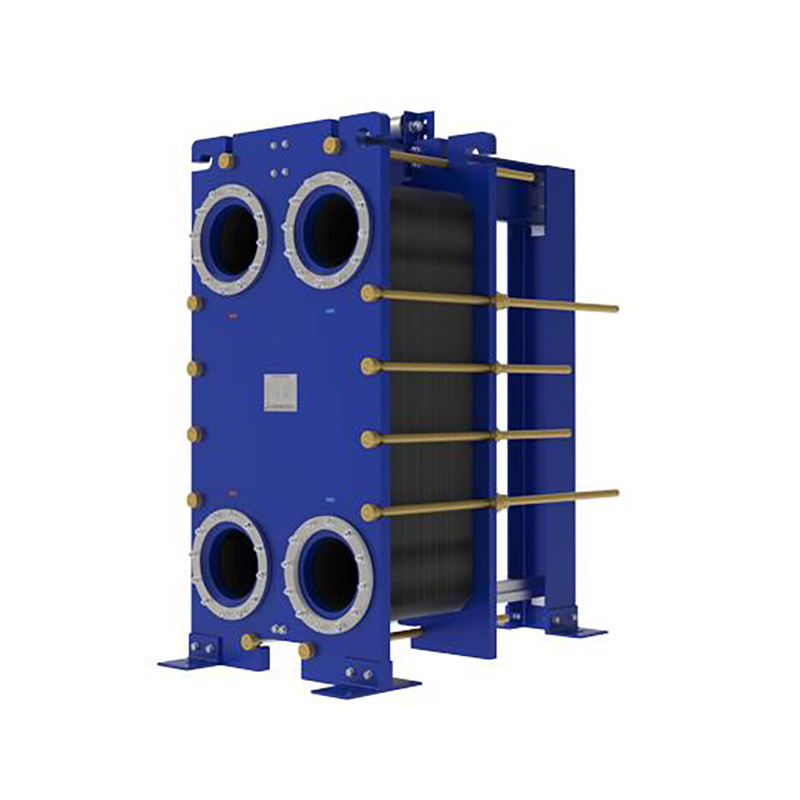

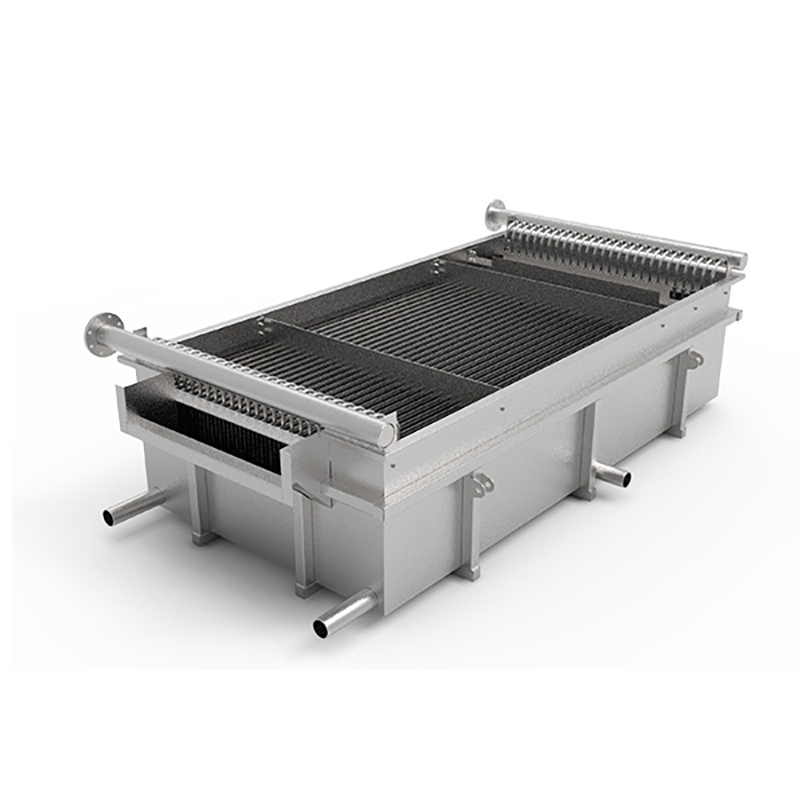

A marine hot water heat exchanger is a critical thermal management device specifically engineered for maritime applications, designed to efficiently transfer heat from a primary heat source, such as the vessel's main engine jacket water system, to a secondary freshwater circuit. This process provides a reliable and continuous supply of heated potable water and water for sanitation and heating systems aboard ships, offshore platforms, and other marine vessels. These units are fundamental components within a ship's hotel load and auxiliary systems, ensuring crew comfort and operational functionality. Constructed to withstand the harsh marine environment, they are typically built from corrosion-resistant materials like cupronickel, titanium, or stainless-steel to handle various water qualities, including seawater on the shell side or as the cooling medium in a plate-type design. Their operation is integral to the vessel's overall energy efficiency, as they utilize waste heat from the engine that would otherwise be dissipated uselessly into the sea through the central cooling system. The design, whether shell and tube, plate, or plate and shell, is chosen based on the application's specific pressure, temperature, and flow rate requirements, making them a versatile and indispensable piece of equipment for any marine engineering system.

The core function of a marine hot water heat exchanger is to harness waste thermal energy from the ship's propulsion and auxiliary diesel engines. In a typical setup, hot jacket water from the engine, which can reach temperatures between 80-90°C (176-194°F), is circulated through the heat exchanger. This primary fluid then transfers its thermal energy to a secondary, lower-temperature freshwater loop without the two fluids mixing. This heated freshwater is subsequently stored in insulated calorifier tanks, ready for on-demand use in galley sinks, showers, cabin heating, and other sanitary services. This process is highly efficient as it recovers energy that is already being produced, significantly reducing the need for electrically powered immersion heaters or boilers, which lowers fuel consumption and associated emissions. For instance, data from maritime engineering studies and manufacturer specifications, such as those from Alfa Laval and SWEP, indicate that a properly sized plate heat exchanger can achieve thermal efficiency ratings exceeding 90%, effectively transferring the vast majority of available waste heat. This direct linkage to the main engine means that hot water production is most effective while the vessel is underway; therefore, systems are often designed with alternative heating elements for use when the main engine is offline. The robust construction is mandated by classification societies like DNV, ABS, and Lloyd's Register, ensuring reliability and safety under constant vibration, rolling, and pitching motions, and exposure to saline environments.

Select the most popular foreign trade service products to meet your diverse needs

Learn more about the dynamics and professional knowledge of the foreign trade industry

Plate heat exchanger gaskets perform 5 key roles: ...

More

A gasket in heat exchanger seals surfaces, blocks ...

MoreAPI 662 defines standards for plate heat exchanger...

More

Compare top frame plate heat exchanger models for ...

More

You can see clear differences between welded block...

More

The dimple plate heat exchanger, also known as the...

MoreSelect the most popular foreign trade service products to meet your diverse needs

Explore more content related to foreign trade services

User Comments

Service Experience Sharing from Real Customers

Michael Rodriguez

Chief EngineerThis marine heat exchanger is incredibly robust and efficient. We've been using it for six months in harsh saltwater conditions, and it shows no signs of corrosion or performance drop. The heat transfer rate is exceptional, significantly reducing our fuel consumption for hot water heating. A top-tier product for any serious vessel.

Sarah Chen

Vessel Operations ManagerOutstanding performance and reliability. Installation was straightforward, and it integrated perfectly with our existing hot water system. The build quality is superior, and it requires minimal maintenance. It has solved all our inconsistent hot water issues on board. Highly recommended for the offshore industry.

David Kowalski

Shipyard Procurement SpecialistA very well-designed and durable heat exchanger. The compact design saves valuable engine room space without compromising on capacity. The titanium construction is worth the investment for its longevity. We are specifying these units for all our new build projects. One point off for the lead time being slightly longer than expected.

James Wilson

CaptainAn absolute game-changer for crew morale on long voyages. Provides a consistent and ample supply of piping hot water for showers and galley use, even when running multiple systems. Its efficiency is remarkable. A critical and reliable piece of equipment that every vessel should have.